Use method of filtering membrane assembly

A filter membrane and component technology, applied in the field of filter membrane components, can solve problems such as reducing the effect of filtration, clogging of impurities inside the equipment, and inability to accurately control the fluid flow, so as to achieve the effect of improving the effect.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

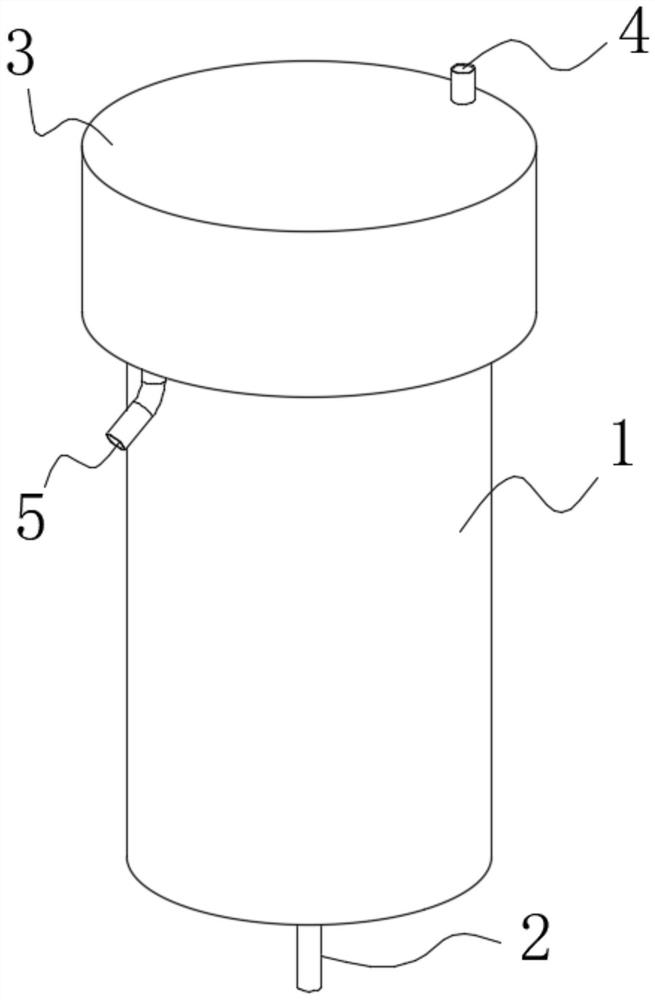

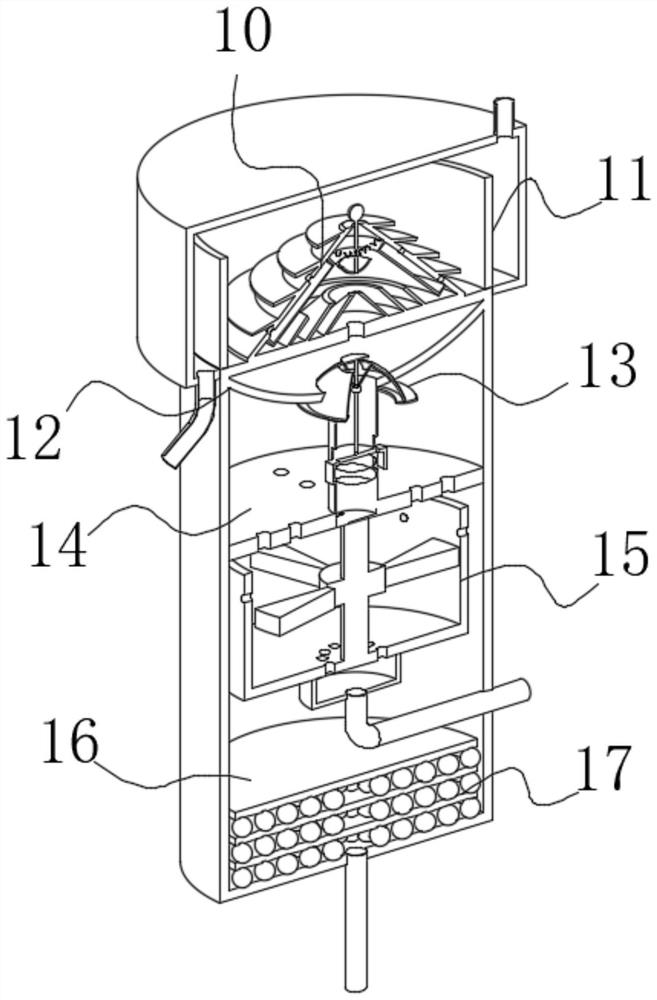

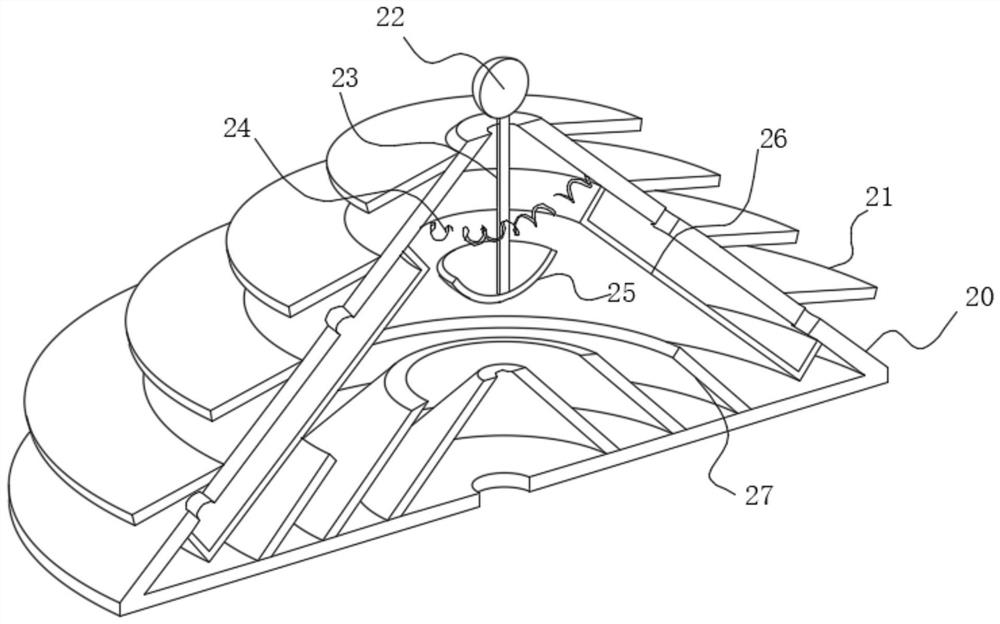

[0029] use Figure 1-Figure 7 A method for using a filter membrane module according to an embodiment of the present invention is described as follows.

[0030] Such as Figure 1-Figure 7 As shown, a method for using a filter membrane module according to the present invention comprises the following steps:

[0031] S1: Place the filter equipment vertically and fix it on the external plane, check whether the appearance of the equipment meets the requirements of normal operation, then pass a small amount of liquid into the filter equipment for trial operation, and check the airtightness and stability of the inside of the equipment;

[0032] S2: After the inside and outside of the equipment have reached the use standard, connect the pipe at the top of the filter equipment to the outside world, gradually increase the amount of water entering the equipment, and the water containing impurities will be filtered and purified by deceleration, centrifugal separation and activated carbon...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com