Construction method for post-pouring coke oven floor ventilation trench and gas pipe trench

A construction method and gas pipe technology, applied in the foundation of the furnace, the processing of building materials, construction, etc., can solve the problems of long travel of concrete conveying pipelines, many joints, and easy leakage of slurry, so as to shorten the construction period, ensure continuity, The effect of small conveying distance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0024] The present invention will be further described below in conjunction with the examples, the purpose is only to better understand the contents of the present invention, therefore, the examples given do not limit the protection scope of the present invention.

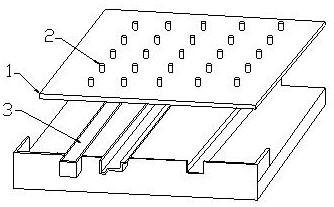

[0025] see Figures 1 to 4 Shown, the post-pouring coke oven floor ventilation ditch provided by the present invention and the construction method of gas pipe ditch, carry out according to the following steps,

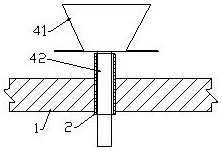

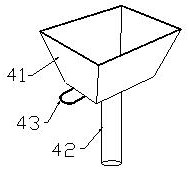

[0026] The first step is to make the string bucket 4 and the chute 5. The string bucket 4 includes a funnel 41, and the bottom of the funnel 41 is provided with a concrete guide tube 42; The cleaning pipe 2 is inserted into the coke oven; the chute 5 is set inside the coke oven, and its lower end is set at the pouring position of the coke oven floor (that is, the ventilation trench 3 or the gas pipe trench).

[0027] In the second step, a certain position on the floor of the coke oven is selected as the st...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com