Nanofiber cable sleeve preparation process

A preparation process and nanofiber technology, applied in the field of cable sleeves, can solve the problems of no automatic cooling, inability to apply evenly, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

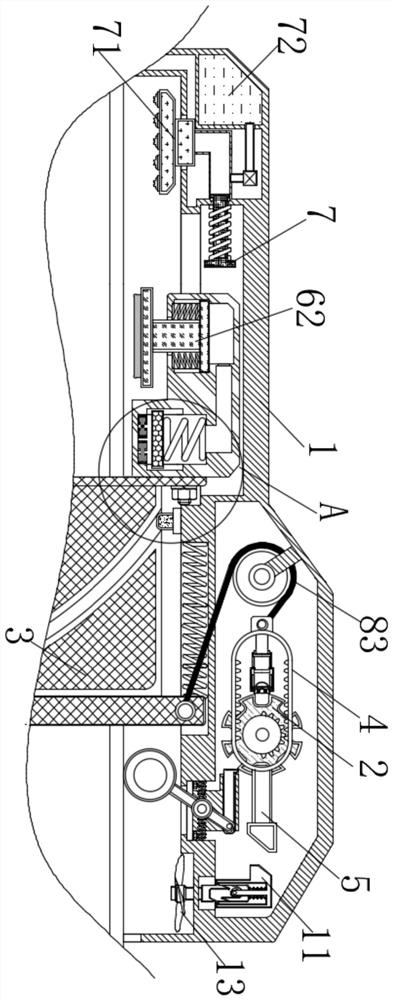

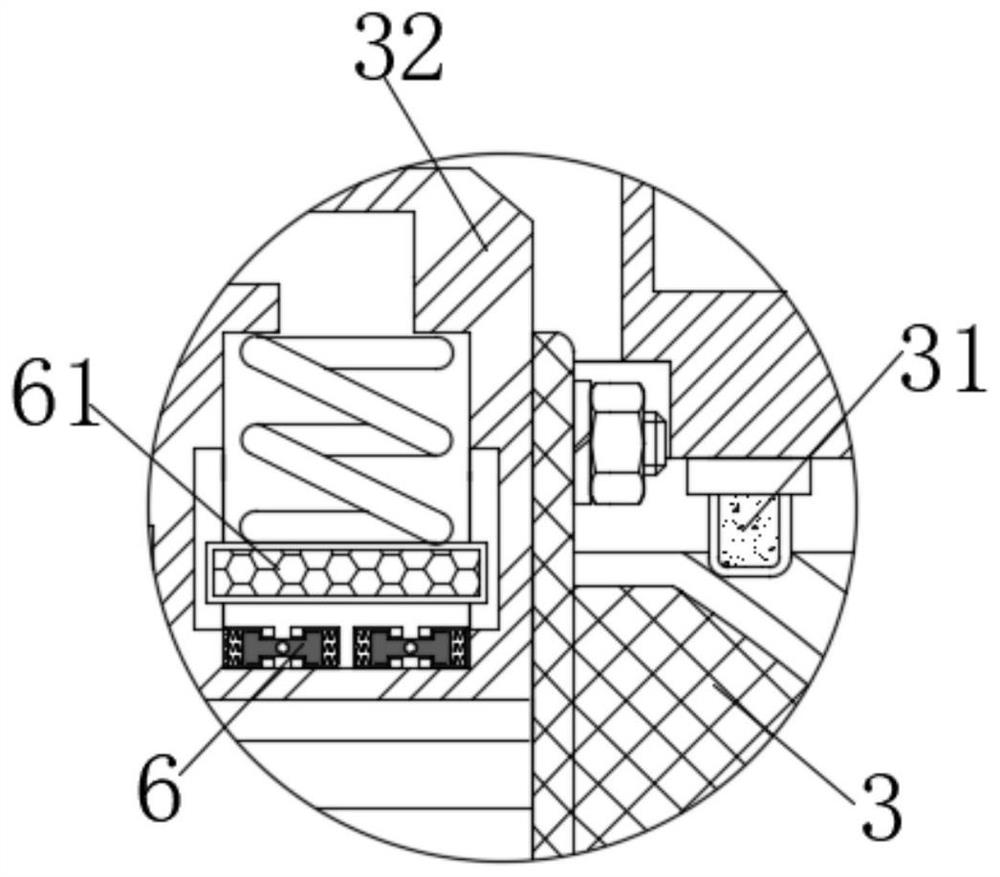

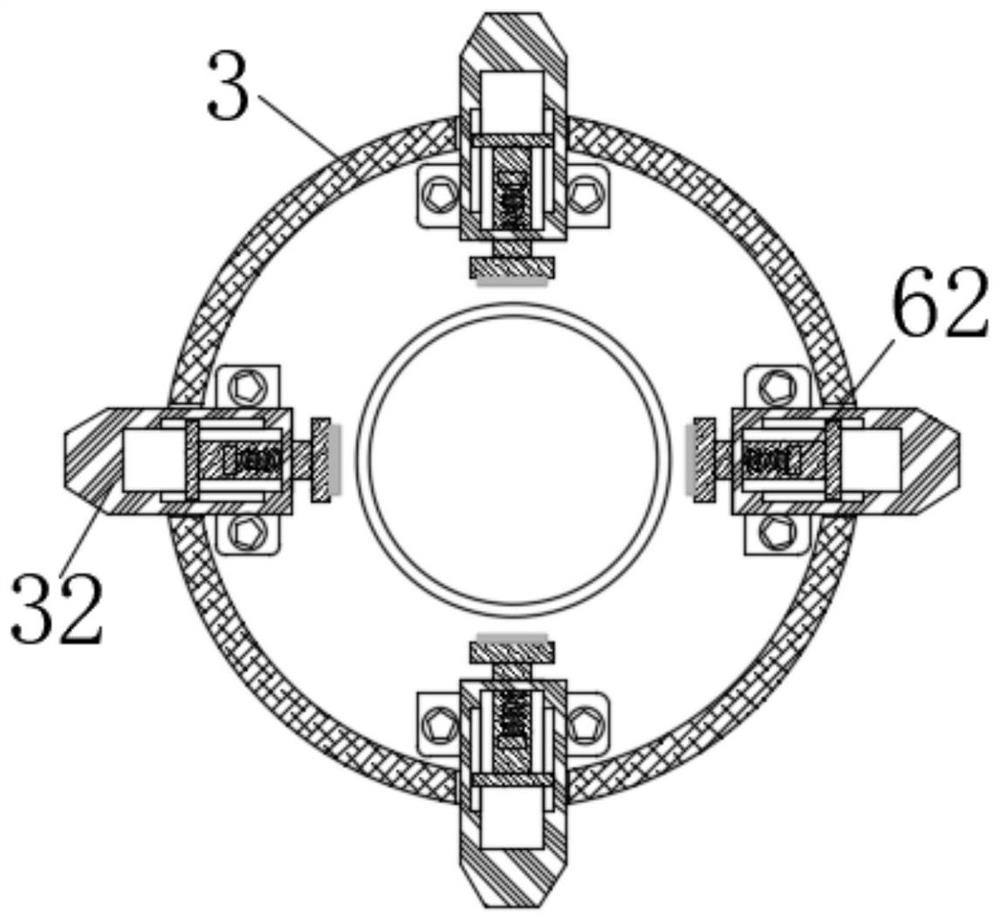

[0026] see Figure 1-3 , a nanofiber cable sleeve preparation process, including a casing 1 and a driving wheel 2, the inside of the casing 1 is slidably connected with a pushing mechanism 3, the upper part of the pushing mechanism 3 is provided with a first block 31, and the left side of the pushing mechanism 3 is fixedly connected with The clamping mechanism 32 is rotatably connected with the intermittent device 4 on the surface of the drive wheel 2 , and the first push rod 5 is fixedly connected with the right end of the intermittent device 4 .

[0027] Further, a notch is opened on the surface of the pushing mechanism 3, and cooperates with the first stopper 31 inside the casing 1, and the electromagnetic device 6 is fixedly connected inside the clamping mechanism 32, and the first magnetic block 61 is arranged on the upper part of the electromagnetic device 6 The magnetic poles of the magnetic field generated by the electromagnetic device 6 are the same as the magnetic po...

Embodiment 2

[0032] see Figure 2-5, a nanofiber cable sleeve preparation process, including a casing 1 and a driving wheel 2, the inside of the casing 1 is slidably connected with a pushing mechanism 3, the upper part of the pushing mechanism 3 is provided with a first block 31, and the left side of the pushing mechanism 3 is fixedly connected with The clamping mechanism 32 is rotatably connected with the intermittent device 4 on the surface of the drive wheel 2 , and the first push rod 5 is fixedly connected with the right end of the intermittent device 4 .

[0033] Further, the bottom of the first push rod 5 is provided with a fixed rod 9, the fixed rod 9 is slidably connected inside the casing 1, and matches with the notch on the surface of the drive wheel 2, the surface of the fixed rod 9 is rotatably connected with a movable rod 10, When the cable enters the inside of the casing 1, the cable drives the fixed rod 9 to slide to the right by squeezing the movable rod 10, so that the fix...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com