Vertical continuous casting equipment for metal billets

A technology for casting equipment and metal billets, which is applied in the field of vertical continuous casting equipment for metal billets, can solve the problems of waste of raw materials, poor stability, and easy to cause deviations, and achieve the effects of improving casting effects, casting efficiency, and stability

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

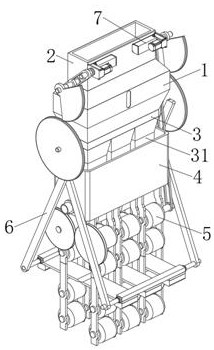

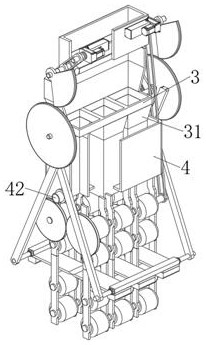

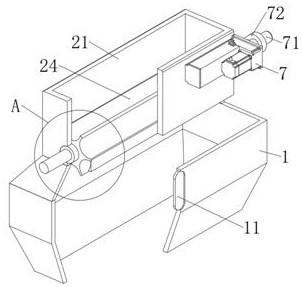

[0026] Example: such as Figure 1-8 As shown, the present invention provides a metal billet vertical continuous casting equipment, comprising a slow material bag frame 1, the top of the slow material bag frame 1 is fixedly equipped with a feed assembly 2, and the bottom end of the slow material bag frame 1 is fixedly installed with a The sub-package frame 3, the bottom end of the sub-package frame 3 is fixedly equipped with a casting package frame 31, the casting package frame 31 is provided with multiple groups that are equidistantly distributed, and the sub-material package frame 3 is provided with the casting package frame 31 Corresponding The multi-component material passes through the groove, and the raw materials buffered in the slow material bag frame 1 enter the corresponding casting bag frame 31 through the multi-component material through the groove to carry out vertical continuous multi-group casting of the metal billet, which effectively improves the casting efficie...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap