Equipment for manufacturing grooved honeycomb core

A technology for slotting honeycomb and equipment, which is applied in the direction of manufacturing tools, metal processing equipment, clamping, etc., can solve the problems of uneven slotting, achieve the effects of improving slotting efficiency, improving displacement stability, and simple operation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] In order to further explain the technical means and effects of the present invention to achieve the intended purpose of the invention, the specific implementation, structure, features and effects of the present invention will be described in detail below in conjunction with the accompanying drawings and preferred embodiments.

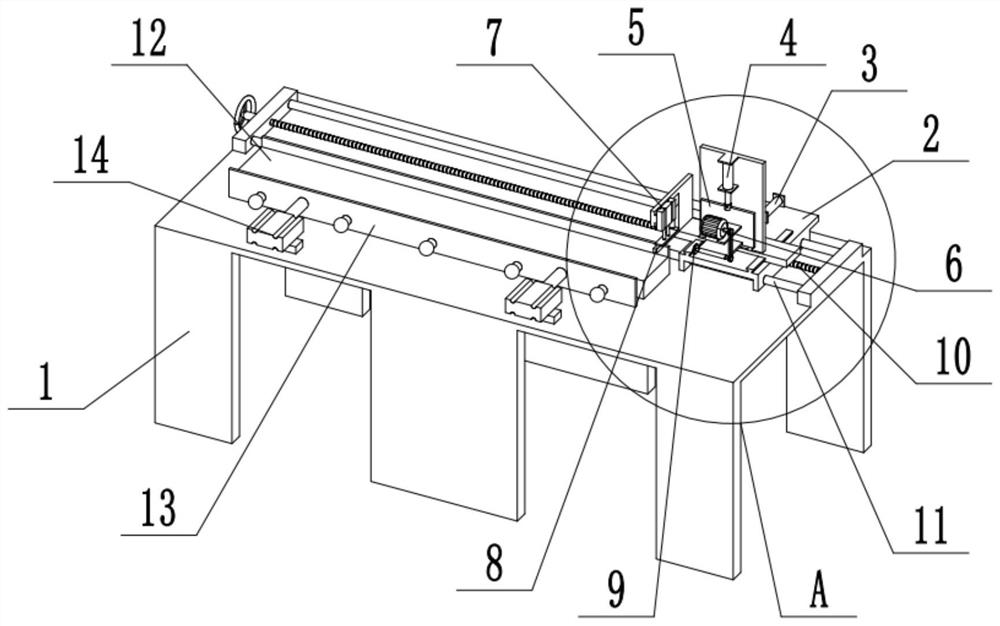

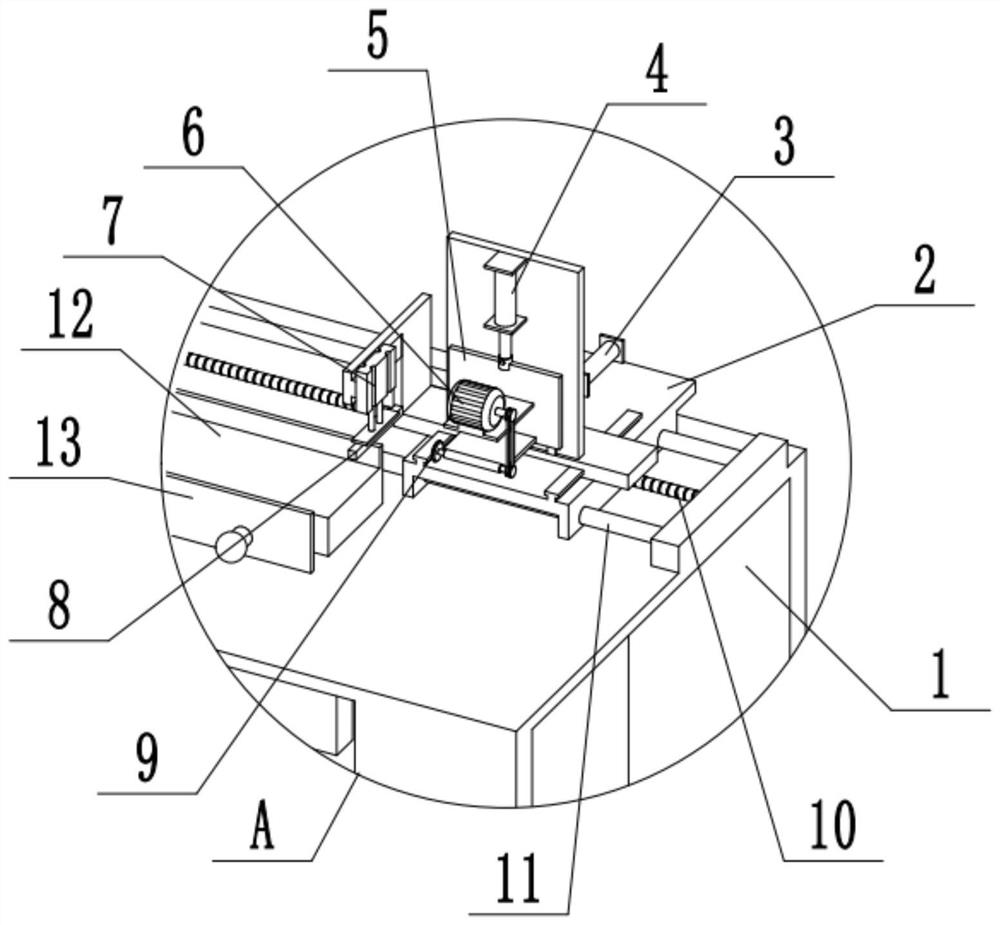

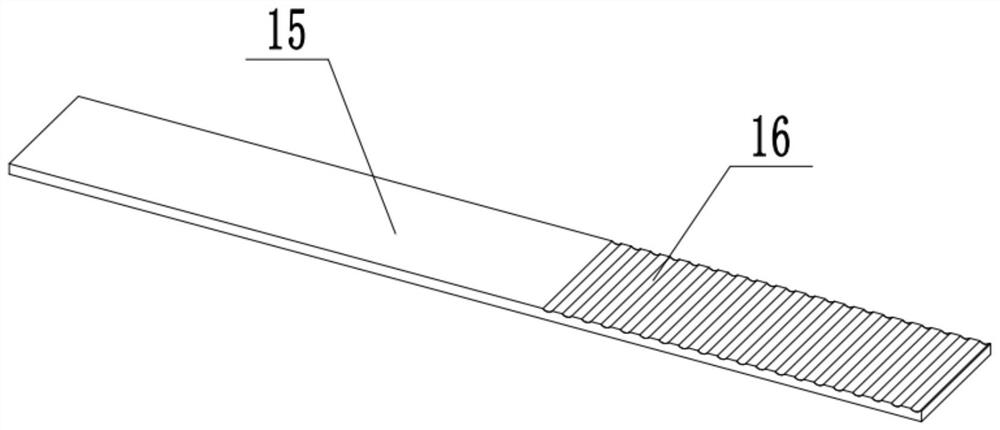

[0022] The reference signs in the accompanying drawings of the description include: working platform 1, function board 2, first cylinder 3, second cylinder 4, slotting support plate 5, motor 6, fourth cylinder 7, pressure plate 8, slotting wheel 9, Lead screw 10, guide rod 11, slotting platform 12, splint 13, third cylinder 14, honeycomb core raw material 15, honeycomb core slotting 16.

[0023] Example figure 1 with figure 2 As shown, including the working platform 1, two guide rods 11 are symmetrically fixed on the rear side of the upper surface of the working platform 1, and a lead screw 10 connected to the working platform 1 in rotation is ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap