Building board arc surface grinding device

A technology of building boards and cambered surfaces, which is used in grinding machines, grinding workpiece supports, grinding machine parts, etc., can solve the problems of excessively large rounded corners, affecting building construction, and inability to complete assembly, and achieves increased quality and The effect of efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

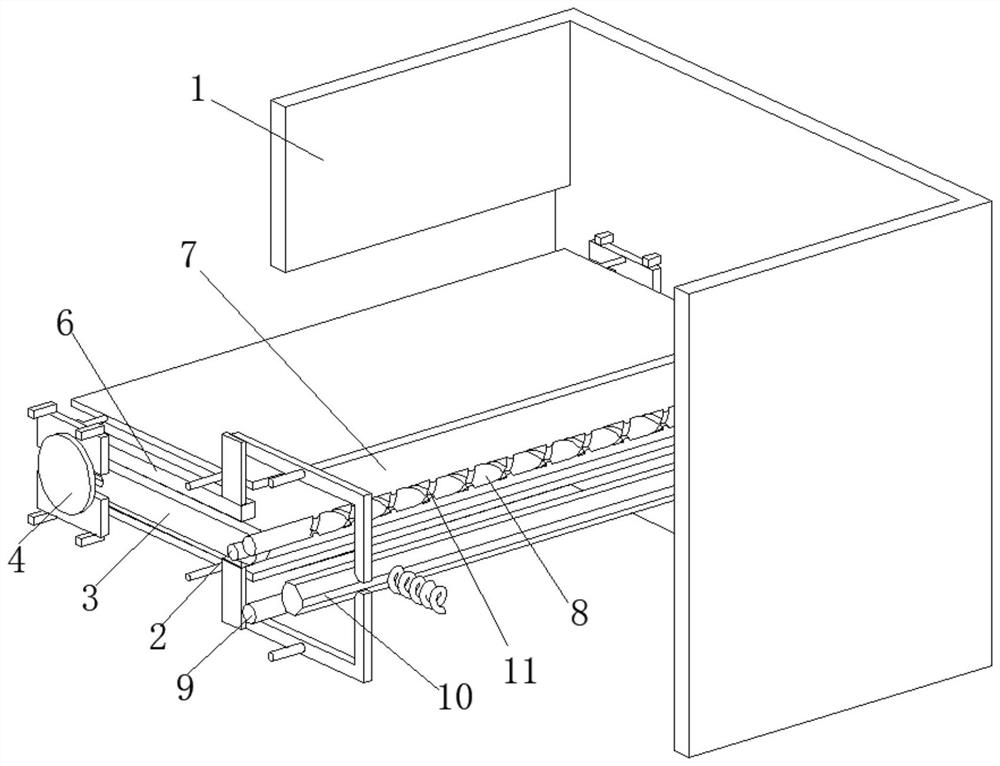

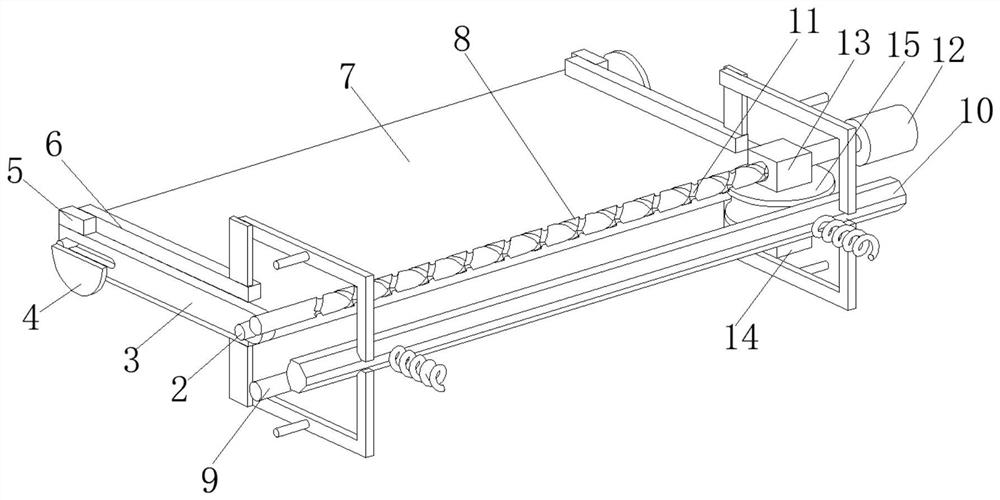

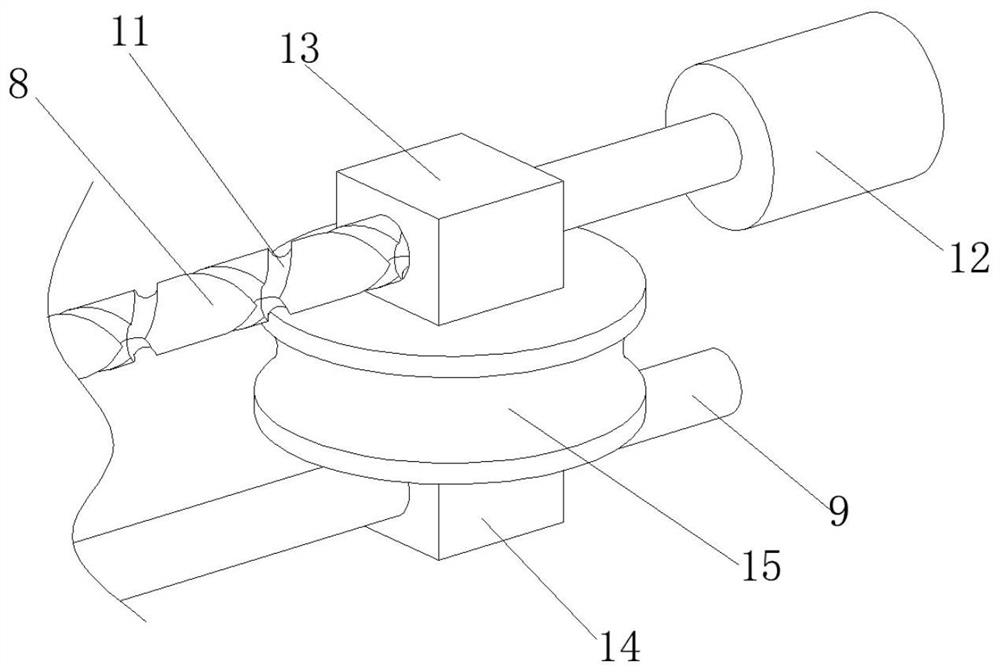

[0027] A kind of arc surface grinding device for building boards, such as Figure 1-Figure 6 As shown, it includes a box body 1, the inner wall of the box body 1 is rotatably connected with a fixed rod 2, the rear end of the fixed rod 2 is welded with a fixed plate 3, the inner wall of the box body 1 is provided with a working mechanism 4, and the top of the fixed plate 3 is welded with a The fixed block 5 is provided with a fixed mechanism 6 at the rear of the fixed block 5, the rear of the fixed plate 3 is movably connected with a sheet material 7, the inner wall of the box body 1 is rotatably connected with a transmission rod 8, and the inner wall of the box body 1 is fixedly connected with a limit Rod 9, the inner wall of box body 1 is fixedly connected with scraper 10 by spring, the surface of transmission rod 8 is provided with spiral groove 11, the rear part of box body 1 is connected with motor 12 by bolt, and the surface of transmission rod 8 is movably connected with ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com