Automatic gear shifting child safety seat

A child safety seat, automatic technology, applied in child seats, child chairs, children's furniture and other directions, can solve problems such as inconvenience in operation, and achieve the effects of simple structure, convenient operation and high degree of automation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0017] Further description will be made below in conjunction with drawings and embodiments.

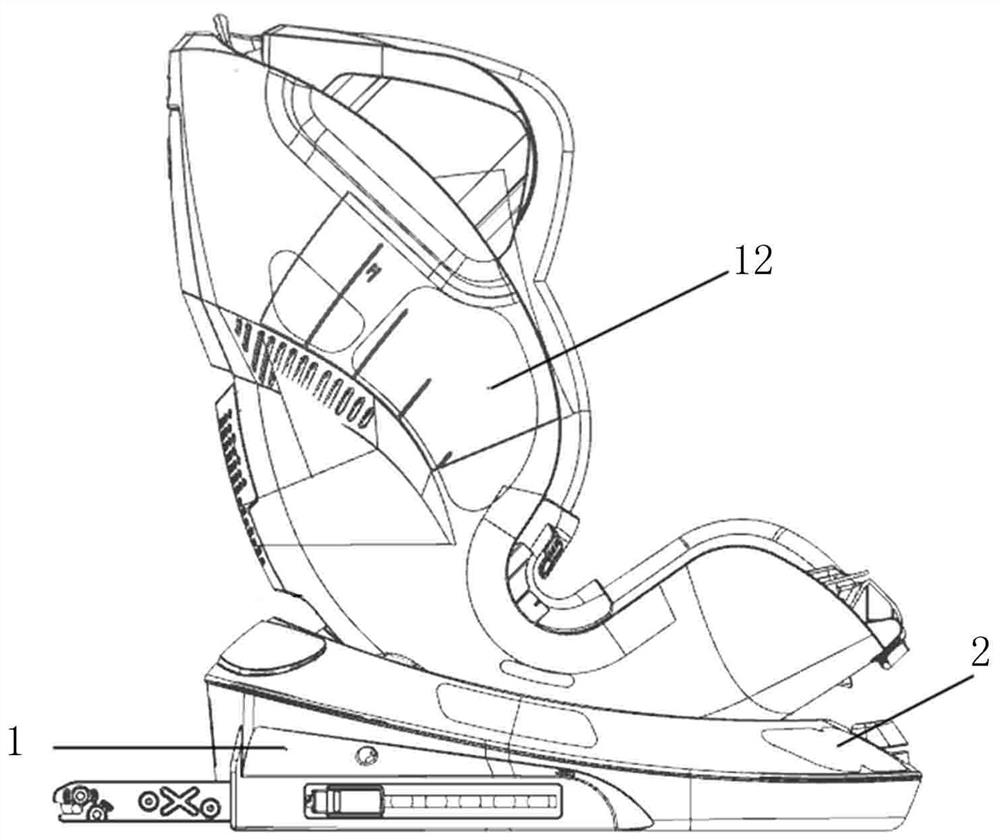

[0018] figure 1 Shown: an automatic shifting child safety seat, comprising a base 1, a seat body 12, and a chassis cover 2 mounted on the base 1.

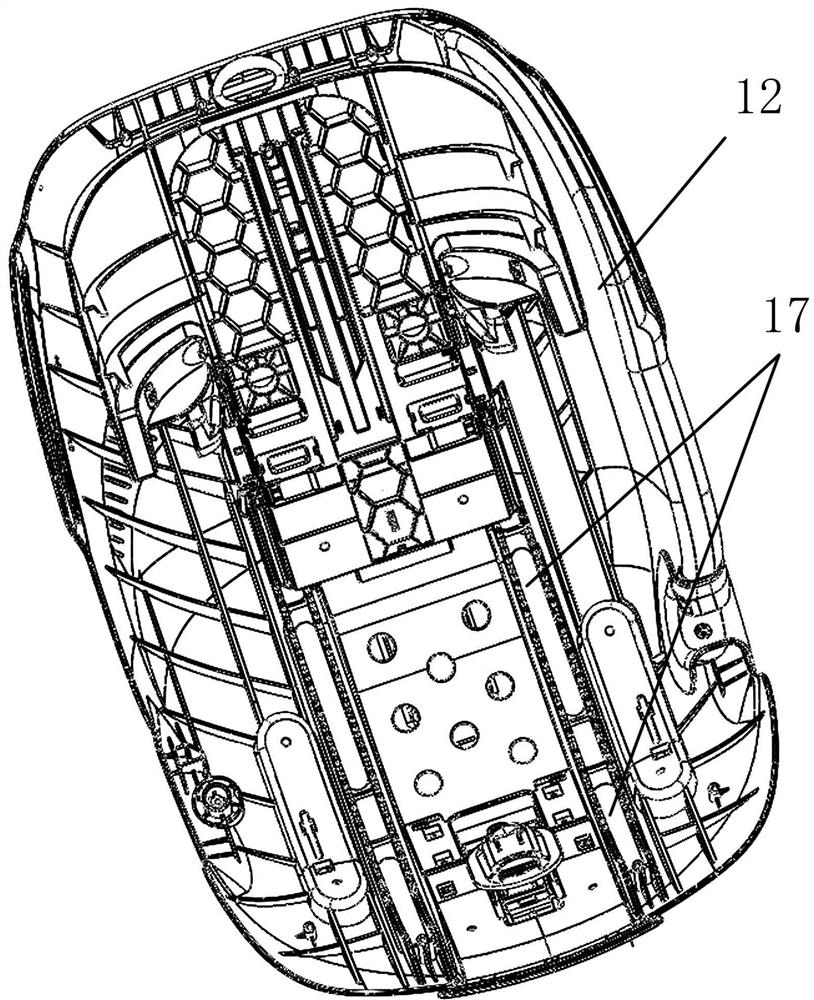

[0019] figure 2 As shown: the seat body 12 is provided with four guide grooves 17 arranged in a rectangular shape and grooved in the front and rear directions.

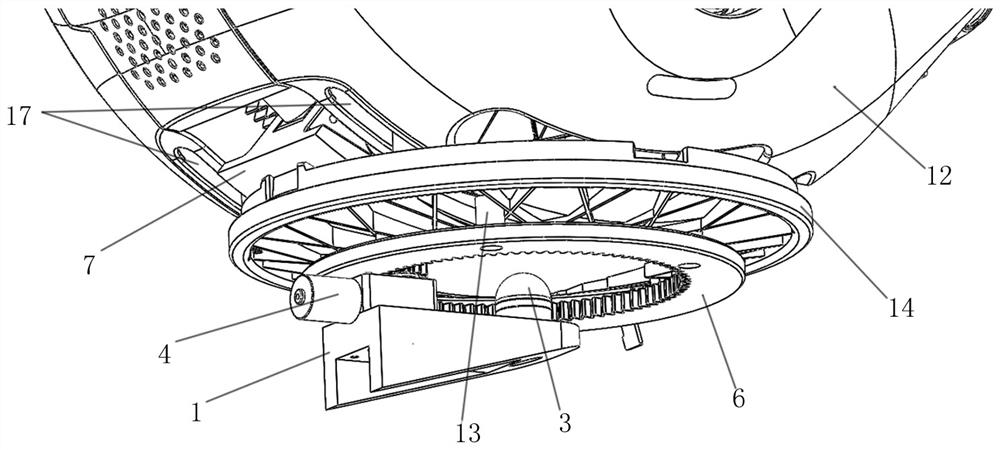

[0020] Figure 3-6 As shown: the upper end surface of the base 1 is an inclined plane, and the high position of the inclined plane supports the rotating stepping motor 4, and the rotating stepping motor 4 drives and connects the pinion gear 5, the pinion gear 5 meshes with the rotating large gear plate 6, the inner ring gear, and the rotating large gear plate 6 The connecting column 13 is hooked under the rotating disk seat 14, and the center position of the rotating disk seat 14 is connected to and supported on the ball head column 13 located on the center axis of the rotatin...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com