Hoisting structure of building machine

A technology for construction machinery and hanging baskets, applied in hoisting devices, lifting equipment safety devices, non-rotational vibration suppression, etc., can solve the problems of easy blockage of drainage holes, easy loosening of bolts, poor fixing firmness, etc., to improve the fixing strength, The effect of avoiding rigid fracture

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

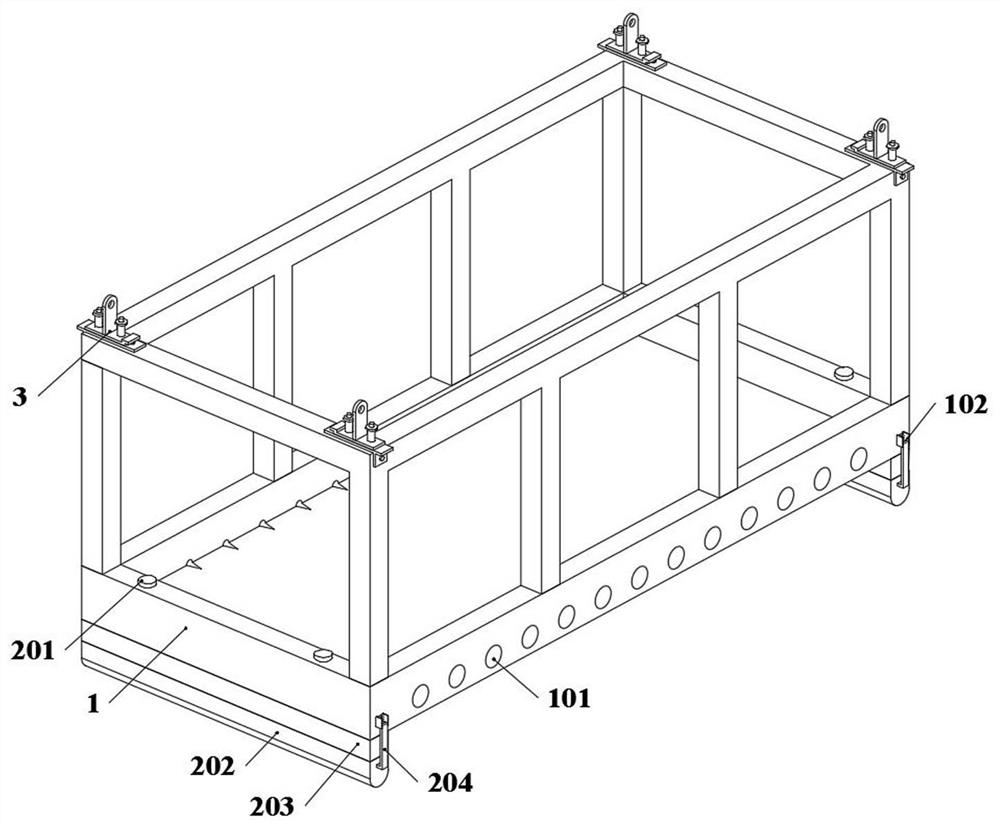

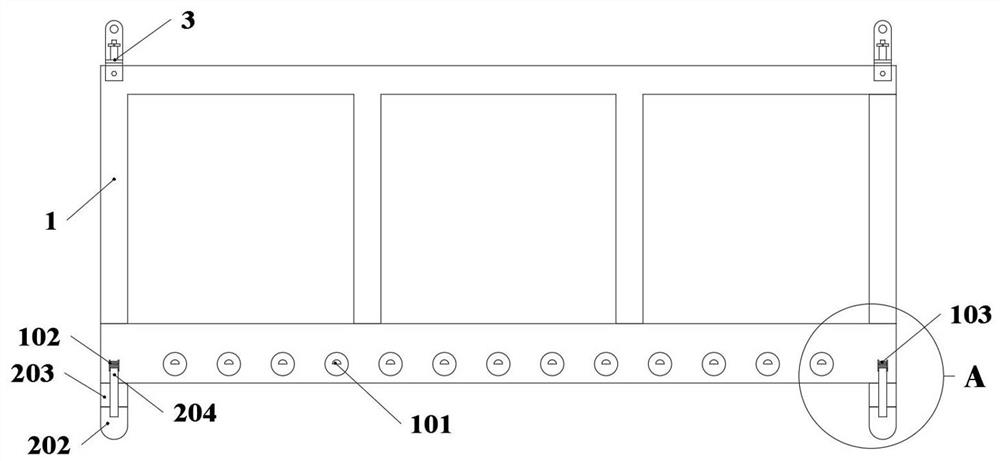

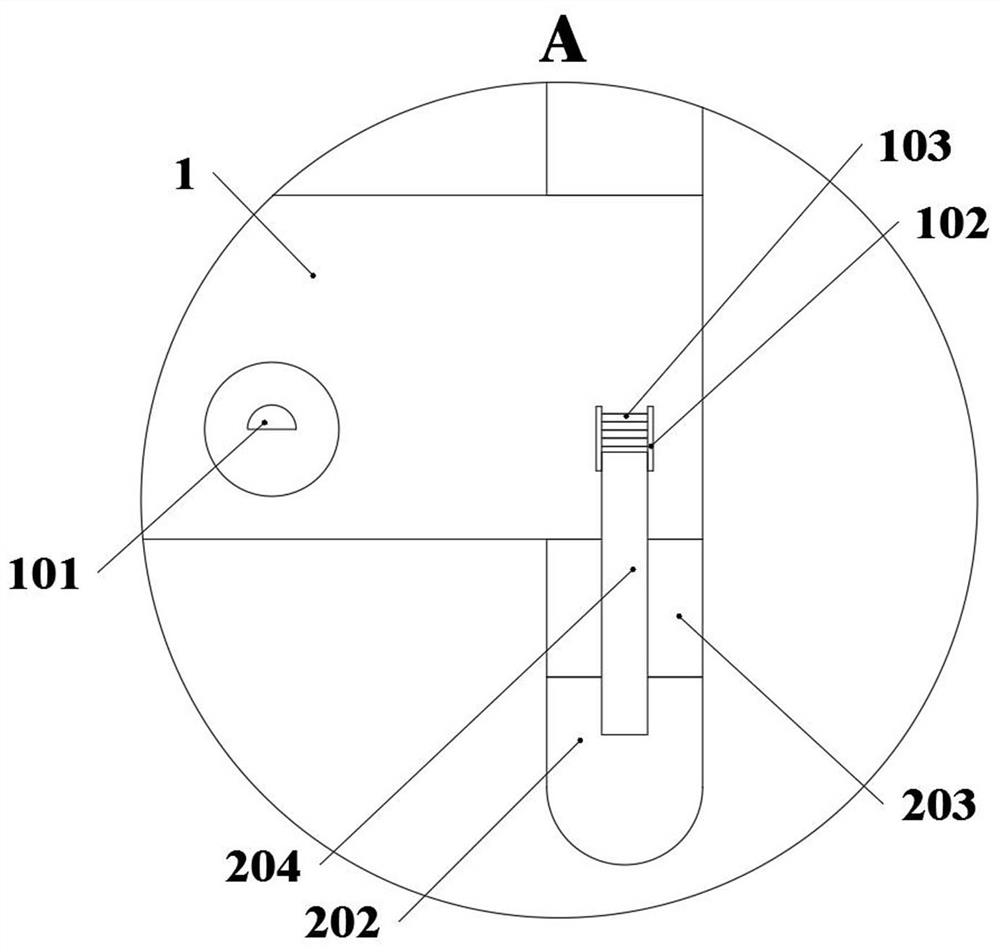

[0039] as attached figure 1 To attach Figure 9 Shown:

[0040]The invention provides a hoisting structure for a construction machine, which includes a hanging basket main body 1; the hanging basket main body 1 is a rectangular frame structure, and two buffer parts 2 are installed on the hanging basket main body 1; Four connecting parts 3; the hanging basket main body 1 includes: snap-in slots 104, four snap-in slots 104 are provided in total, and the four snap-in slots 104 are all set on the hanging basket main body 1, and the four snap-in slots 104 Both are T-shaped groove-shaped structures; the connecting part 3 includes: a seat body 301, on which the fixing bolt A303 and the fixing bolt B309 for fixing the seat body 301 and the main body of the hanging basket 1 are plugged, and the fixing bolt A303 and the fixing bolt Both B309 are threaded with the main body 1 of the hanging basket; the clamping protrusion 302 is welded on the seat body 301, and the clamping protrusion ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com