A highly reliable hydrogen tank storage structure

A storage structure and hydrogen tank technology, applied in the direction of gas processing/storage, gas/liquid distribution and storage, container discharge methods, etc., can solve the problems of not being able to be fixed in the same device, so as to improve safety and stability Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

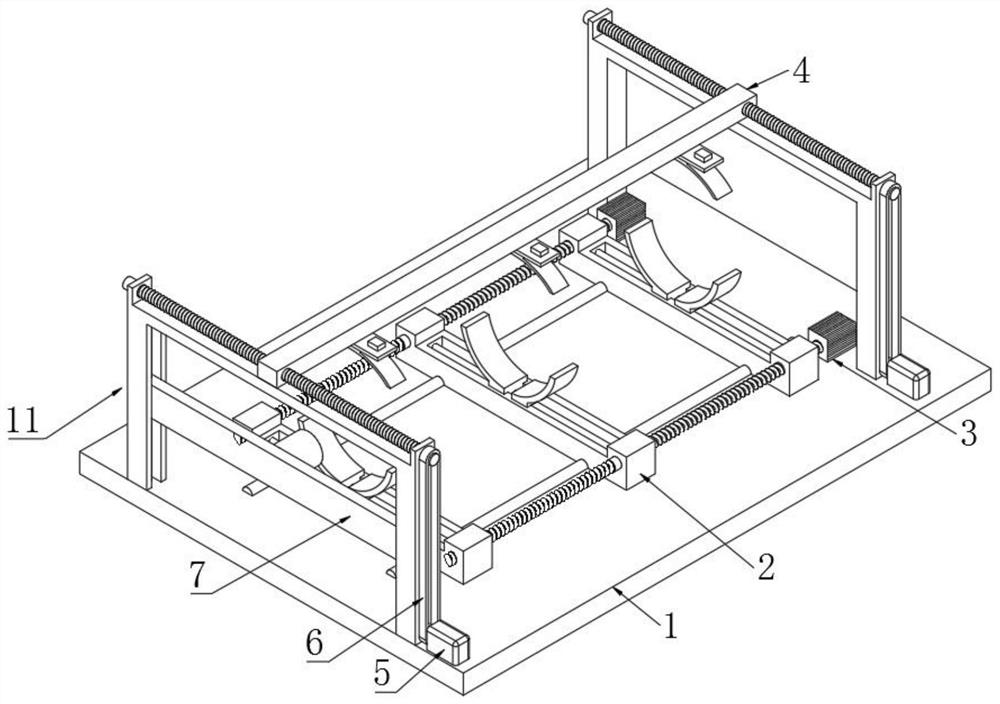

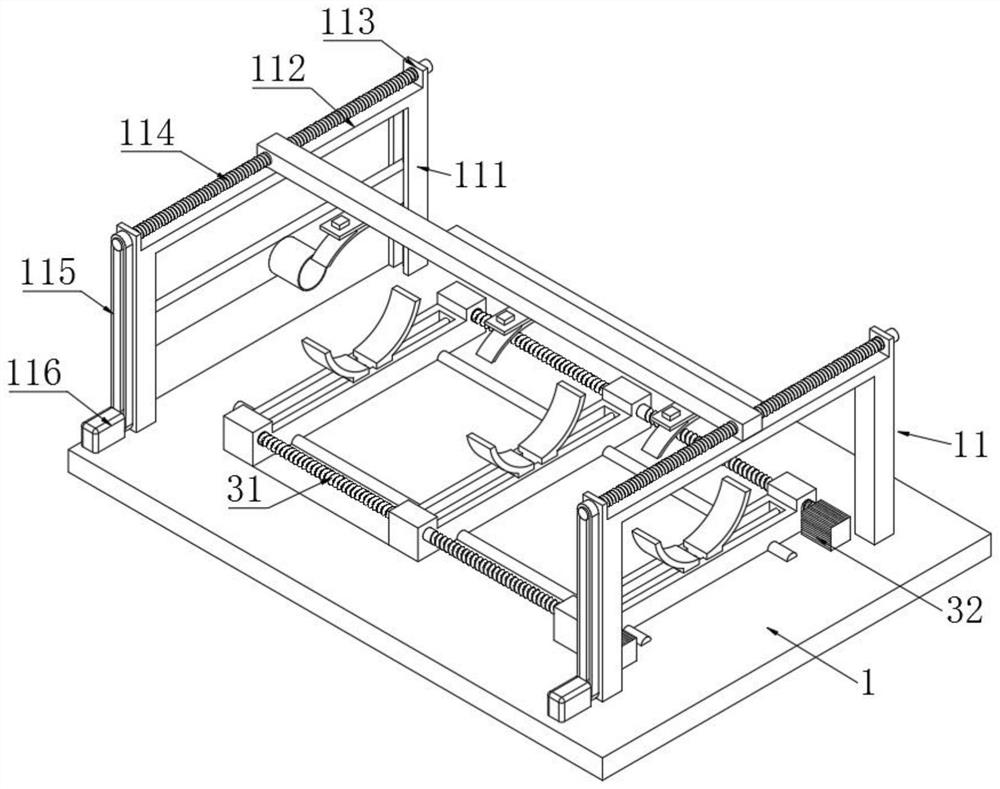

[0050] like figure 1 , figure 2 As shown, the present invention provides a highly reliable hydrogen tank storage structure, comprising:

[0051] Bottom plate 1; both sides of the bottom plate 1 are provided with mounting brackets 11 that are perpendicular to the bottom plate, the mounting bracket 11 includes a beam 112 and two columns 111, the beam 11 is installed on the top of the two columns 111, and the bottoms of the two columns 111 are connected to the bottom plate. 1 connection;

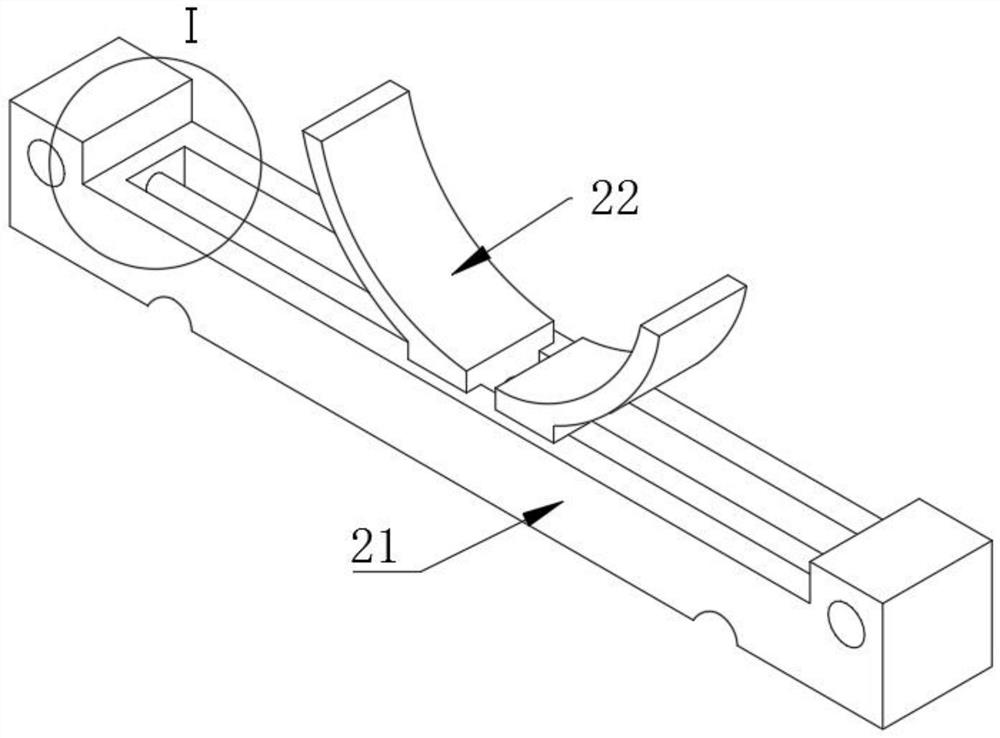

[0052] Three clamping devices 2; the three clamping devices 2 are arranged in the same horizontal direction, each clamping device 2 can be slidably installed on the base plate 1, the sliding direction is the first direction, the first direction is perpendicular to the vertical direction, the clamping device 2 The holding device 2 is parallel to the mounting frame 11, and the hydrogen tank is placed on the three holding devices;

[0053] Drive mechanism; used to drive the two clamping device...

Embodiment 2

[0078] like Figure 12 As shown, this embodiment is further improved on the basis of Embodiment 1: an extrusion device 8 is provided on the right side of the bottom plate, and the extrusion device 8 cooperates with the valve protection device 7 to further fix the hydrogen tank 100 back and forth, improving the Stability of the hydrogen tank 100 .

[0079] The extrusion device 8 includes a fixed plate 81, an electric push rod 82, and an extrusion plate 83. The fixed plate 81 is installed on the base plate 1 and is perpendicular to the base plate 1, and the electric push rod 82 is installed on the fixed plate 81. The push rod of the electric push rod The ends are connected to a pressing plate 83 for pressing the bottom of the hydrogen tank 100 .

[0080] When the present invention is used: first adjust the position of the clamping device 2 according to the length of the hydrogen tank, start the driving mechanism to adjust the position of the clamping device, ensure that the hyd...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com