Transformer substation inspection robot indoor positioning method based on information fusion

An inspection robot and indoor positioning technology, which is applied in the direction of instruments, electromagnetic radiation induction, computer components, etc., can solve the problems of accumulation and lack of visual positioning, and achieve the effects of strong pertinence, fast convergence, and accurate pose information

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0045] The present invention will be described in detail below in conjunction with the accompanying drawings and specific embodiments.

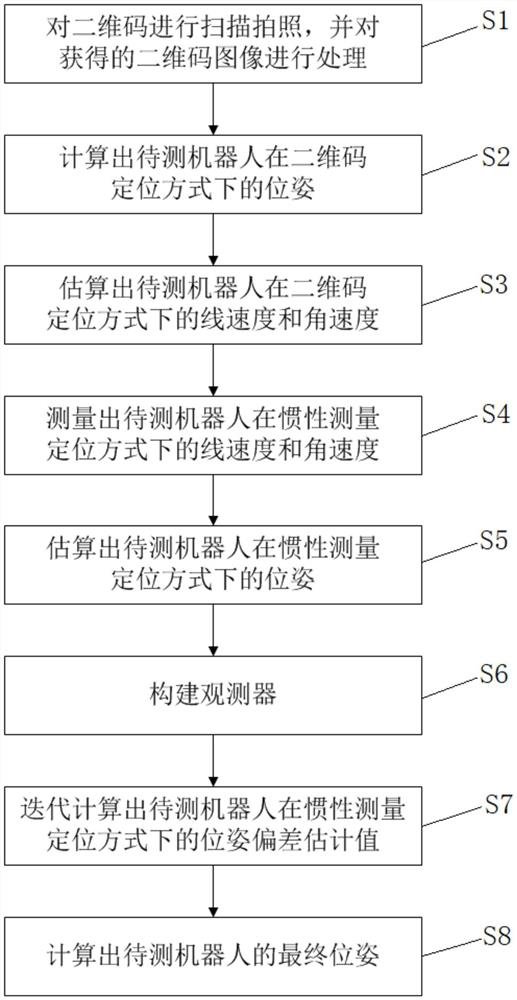

[0046] Such as figure 1 As shown, an indoor positioning method for a substation inspection robot based on information fusion includes the following steps:

[0047] S1. Use the camera installed in the center of the robot to be tested to scan and take pictures of the two-dimensional code, and process the obtained two-dimensional code image, specifically including:

[0048] S11. Perform grayscale processing on the obtained two-dimensional code image to obtain a grayscale image.

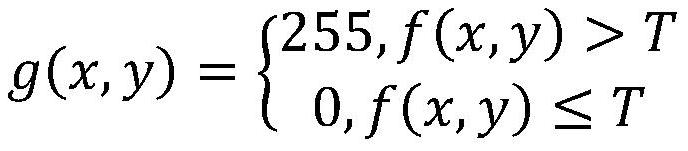

[0049] S12. Perform binarization processing on the obtained grayscale image, that is, change the grayscale values of all pixels in the grayscale image to 0 (black) or 255 (white), to obtain a binarized image.

[0050] In order to obtain ideal results, it is necessary to determine a threshold to distinguish and classify the gray value of the pixels in the grayscale i...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com