Suspension motor rotor suspension position, deflection angle and rotating speed integrated detection system and application

A technology of deflection angle and motor rotor, applied in the direction of measuring devices, instruments, etc., can solve the problems of low resolution, complex structure of rotor detection device, poor measurement position and speed detection accuracy, etc., to eliminate common mode interference and improve speed detection Accuracy and sensitivity, the effect of improving detection accuracy and sensitivity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

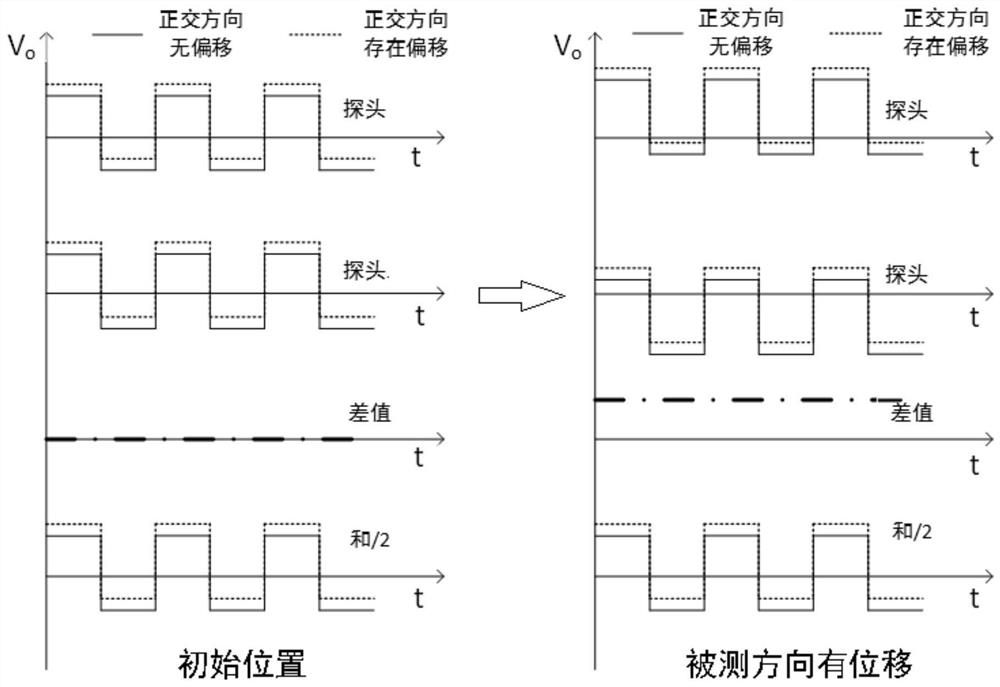

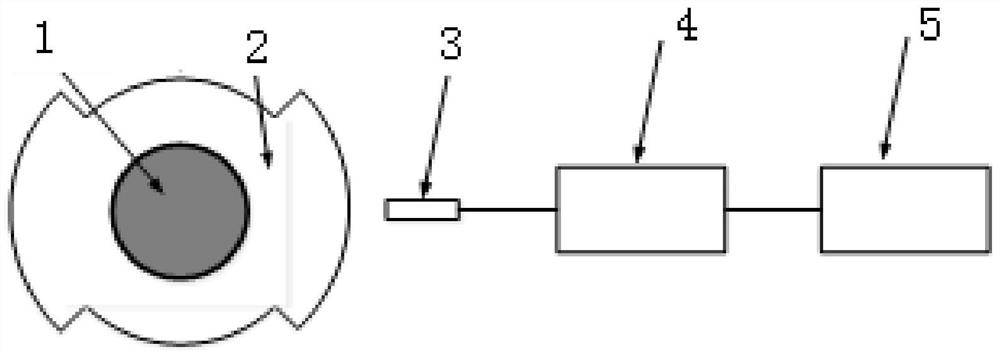

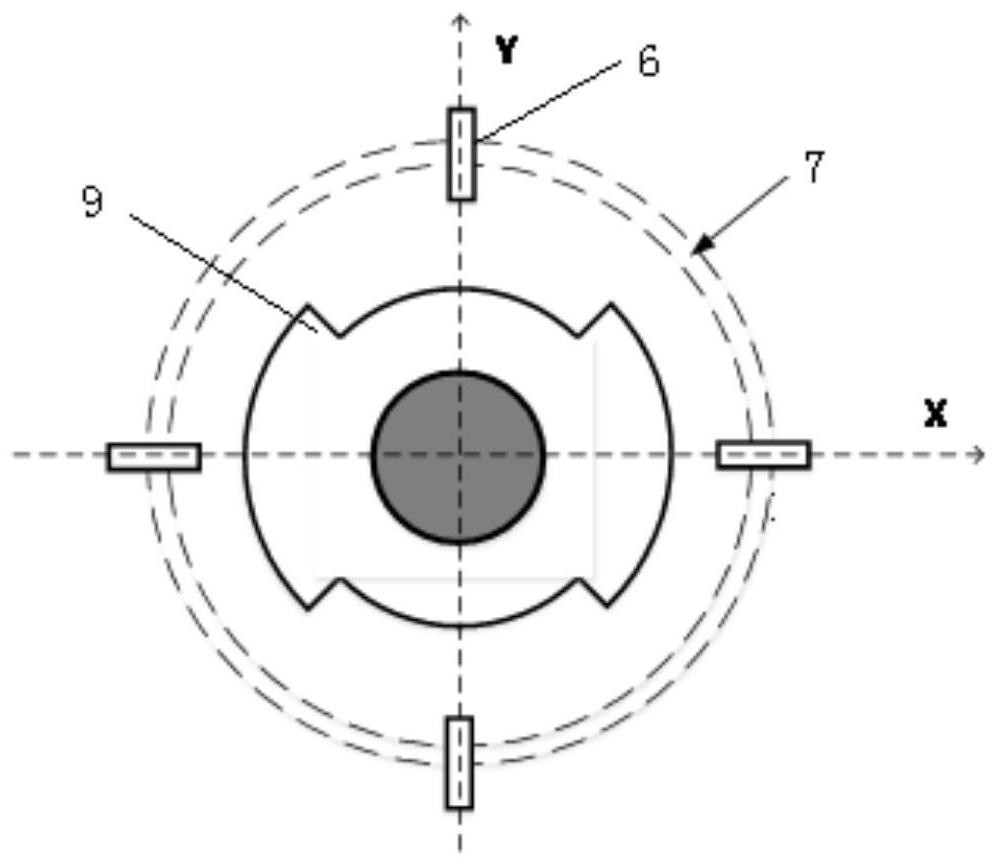

[0048] Such as Figure 2-3 As shown, this embodiment provides an integrated detection system for the suspension position, deflection angle and rotational speed of the rotor of a suspension motor, including a radial test piece 2, an eddy current sensor 3, a front processor 4 and a processor 5, wherein the eddy current sensor 3 is connected with a front-end device 4, and the front-end device 4 is connected with a processor 5, the front-end device 4 is used to supply power to the eddy current sensor 3 and detect and analyze the circuit, and the processor 5 is used to process the measurement results of the eddy current sensor and eliminate the rotor Influence of radial suspension position eccentricity on detection result accuracy.

[0049] The radial test piece 2 includes an annular cylinder, and the outer symmetrical protrusion of the annular cylinder is provided with an arc segment 9, and the arc segment is concentric with the annular cylinder.

[0050] There are at least 2 arc...

Embodiment 2

[0067] An application of an integrated detection system for the suspension position, deflection angle and rotational speed of the rotor of a suspension motor. The operation steps are as described in Embodiment 1. The difference is that the zero adjustment tooling 8 includes a hollow cylinder with an open end, and the bottom of the hollow cylinder is A cylinder is set at the center, such as Figure 4 As shown, the inner diameter of the hollow cylinder is the same as the outer diameter of the annular shell, and it is used to fix the annular shell. The diameter of the cylinder is the same as that of the rotor shaft. The center position of the radial test piece is the same as the center position during work, so as to adjust the zero position of the eddy current sensor.

Embodiment 3

[0069] An application of an integrated detection system for the levitation position, deflection angle, and rotational speed of the rotor of a levitation motor. The operation steps are as described in Embodiment 1. The difference is that in step (1), four eddy current sensors are respectively arranged at both ends of the rotor. , determine the axial installation distance L of the eddy current sensors at both ends, and the ratio of the displacement difference (y1-y2) measured by the eddy current sensors in the corresponding directions at both ends to the axial installation distance (L) is the rotor deflection angle in this direction The tangent value tanα, the arctangent calculation can get the deflection angle α of the rotor, the calculation principle diagram is as follows Figure 10 shown.

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com