Method for producing eicosapentaenoic acid alkyl ester-containing composition

A technology of eicosapentaenoic acid alkyl ester and manufacturing method, which is applied in the fields of medical preparations containing active ingredients, fatty acid preparation/refining, food science, etc., and can solve problems such as difficult purification of EPA, and achieve low ratio and high content little effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

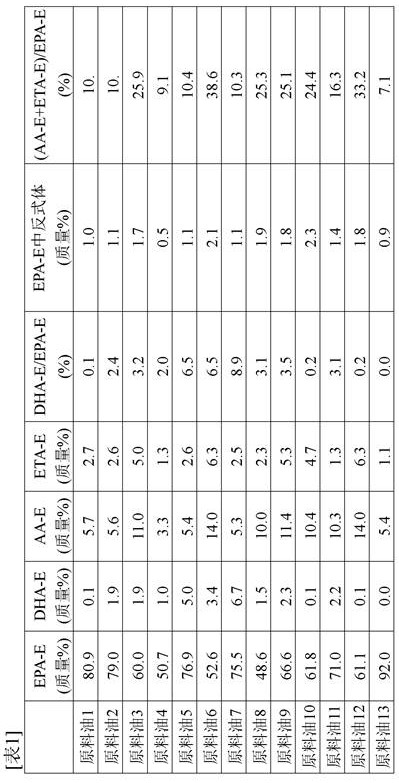

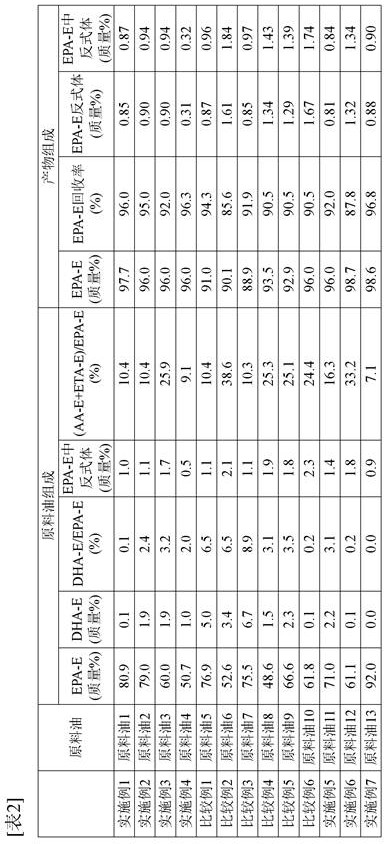

[0073] Hereinafter, examples are given to illustrate the present invention in more detail, but the present invention is not limited to these examples.

reference example 1

[0074] (Reference Example 1) Analysis of Fatty Acid Composition Ratio

[0075] 12.5 mg of the measurement sample was diluted in 1 mL of n-hexane, and the content ratio of each fatty acid in the total fatty acids was analyzed under the following conditions using a gas chromatography analyzer (Type 7890GC; manufactured by Agilent Technologies). The results are shown in mass % converted from the area of the chromatogram.

[0076]

[0077] Injection port temperature: 250°C, split ratio: 10.

[0078]

[0079] Column: DB-WAX 0.25mm×30m manufactured by J&W;

[0080] Column temperature: 210°C;

[0081] He flow: 1.0mL / min, He pressure: 20 PSI.

[0082]

[0083] h 2 Flow: 40mL / min, air flow: 450mL / min;

[0084] He flow rate: 1.00 mL / min, DET temperature: 260°C.

[0085] The fatty acids analyzed were as follows. EPA-E: Eicosapentaenoic acid ethyl ester, DHA-E: Docosahexaenoic acid ethyl ester, AA-E: Arachidonic acid ethyl ester, ETA-E: Eicosatraenoic acid ethyl ester .

...

Embodiment 1

[0092] Thoroughly stir and mix 30g of raw material oil 1 and 14mL of cyclohexane to dissolve it. 41 g of the obtained solution and 150 g of a silver salt solution (50 mass % silver nitrate aqueous solution) were put into the flask, and it stirred at 300 rpm at 20 degreeC for 20 minutes in nitrogen atmosphere (oxygen concentration 0.4%). The liquid after stirring was left still at 20° C. for 15 minutes, and the separated organic layer and aqueous layer (silver salt solution containing PUFA-silver complex) were collected respectively. Add 150g of newly prepared silver salt solution to the recovered organic layer, stir at a speed of 300rpm at 20°C for 20 minutes under a nitrogen environment (oxygen concentration 0.4%), and leave the stirred liquid for 15 minutes at 20°C. minute. Recover the separated water layer, add 15mL hexamethylene therein, stir 20 minutes with the speed of 300rpm at 20 ℃, the liquid after stirring is left standstill at 20 ℃ for 15 minutes, reclaim the separ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap