Industrial robot clamping device

An industrial robot and clamping device technology, applied in the field of manipulators, can solve the problems of affecting clamping action, heavy clamping force adjustment, cumbersome clamping mechanism operation, etc., and achieve the effect of stably clamping goods and stable clamping force

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

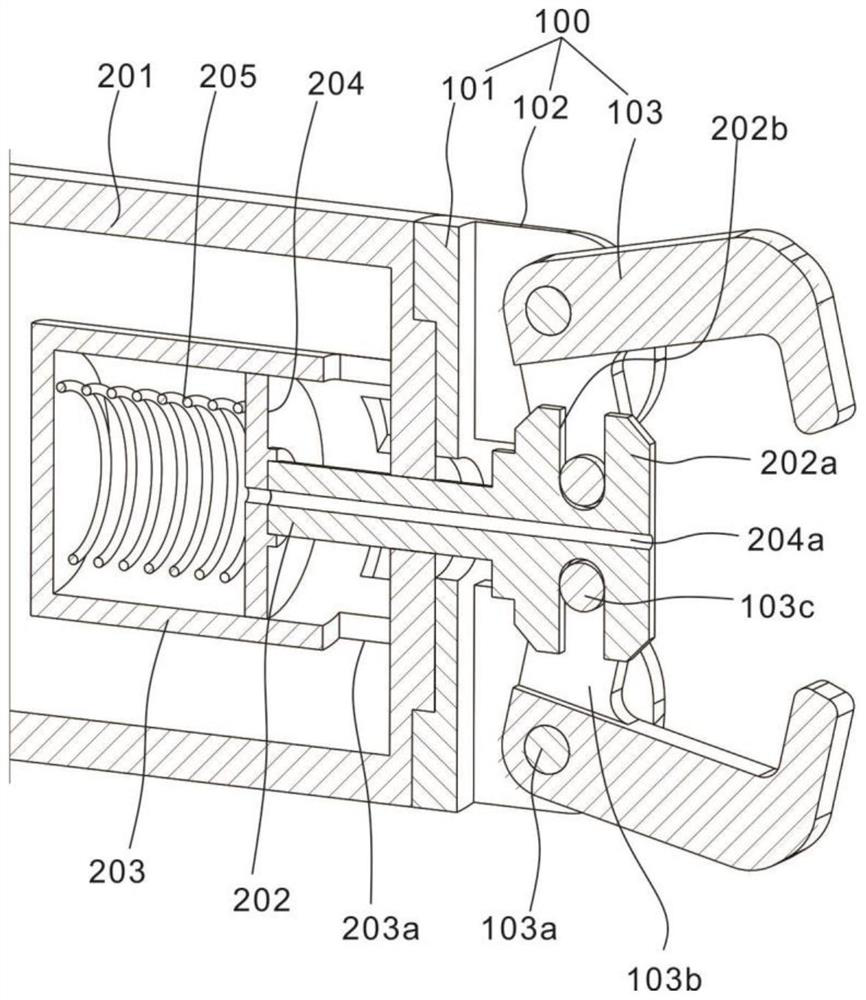

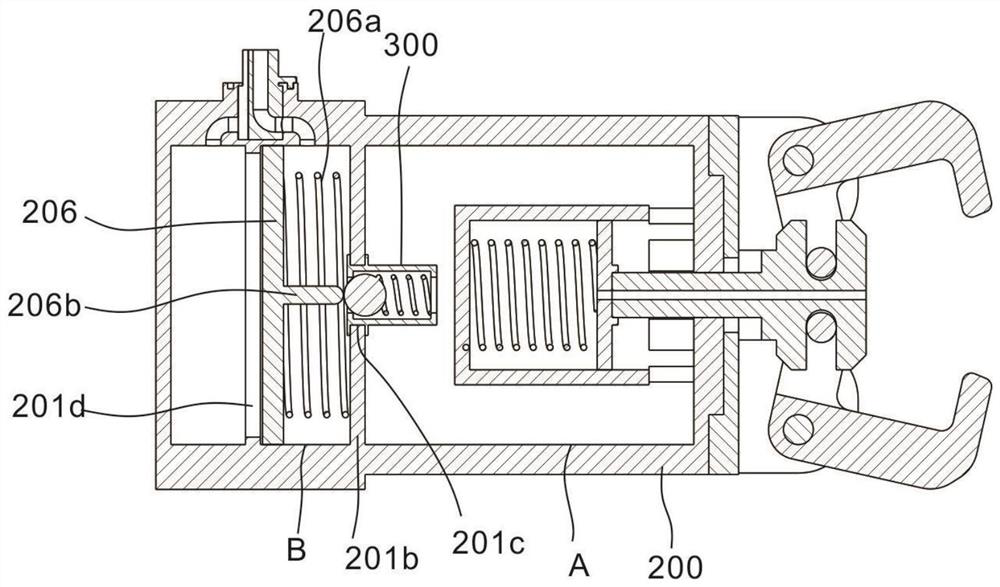

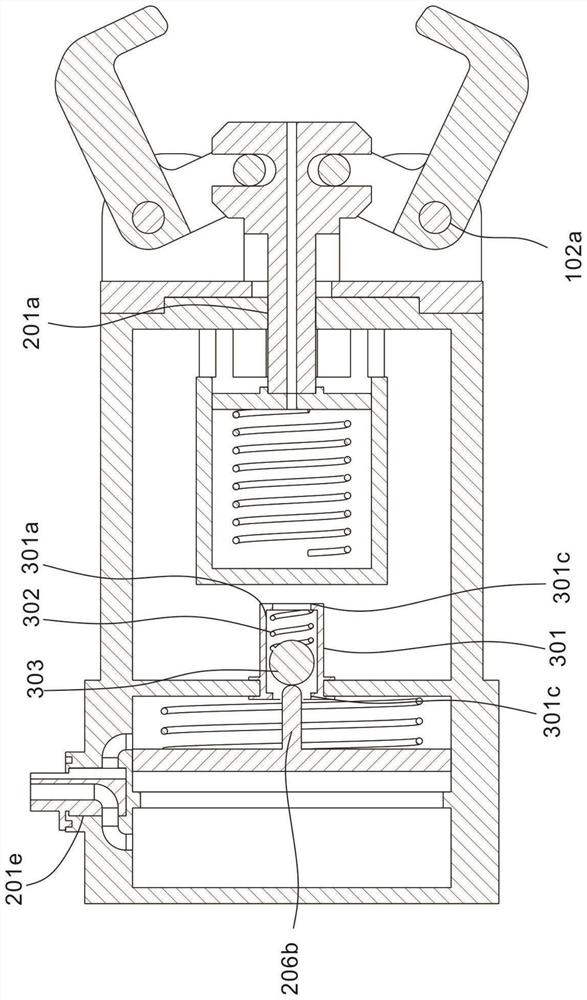

[0032] refer to Figure 1-5 , the present embodiment provides a clamping device for an industrial robot, including a clamping assembly 100 and a control assembly 200, wherein the clamping assembly 100 is used to clamp an object, and the control assembly 200 is used to control the clamping state of the clamping assembly 100.

[0033] The clamping assembly 100 includes a fixing plate 101, on which the fixing plate 101 is symmetrically provided with a mounting plate 102, the mounting plate 102 is arranged perpendicular to the fixing plate 101, the mounting plate 102 is provided with a first hole 102a, and the mounting plate 102 is connected with a claw 103 , the claw 103 is C-shaped, the claw 103 is provided with a first shaft 103a, the first shaft 103a is at a bend of the claw 103, the first shaft 103a is embedded in the first hole 102a, the mounting plate 102, the claw 103 are provided with a pair; so the two claws 103 are arranged oppositely, and the ends of the two claws 103 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com