Folding, dispensing and online ink-jet printing device and ink-jet printing method

A coding and dispensing technology, applied in printing devices, measuring devices, optical devices, etc., can solve problems such as coding errors, coding blur, position deviation, etc., to improve coding accuracy, positioning accuracy, and convenience The effect of positioning

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

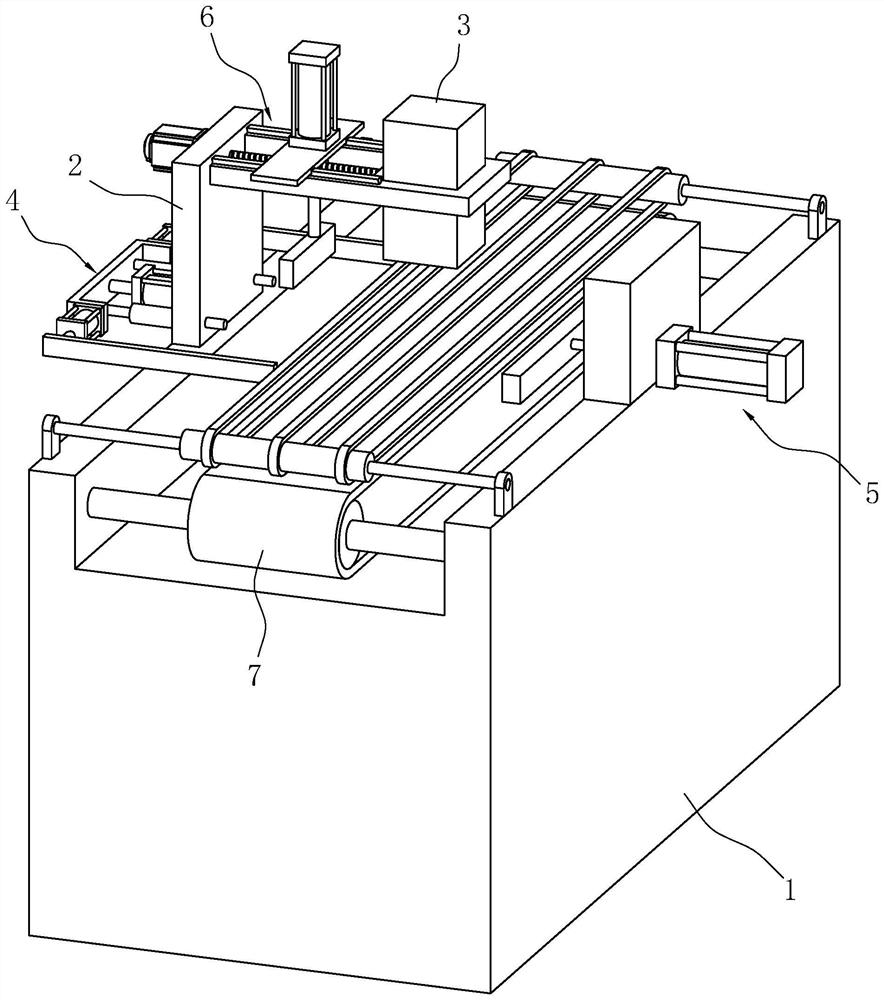

[0043] The embodiment of the present application discloses an online coding device for folding glue dispensing. refer to figure 1 , the folding page dispensing online inkjet device includes a base 1, a conveyor belt 7 set in the base 1 and a mounting frame 2 set on the base 1, and the mounting frame 2 is provided with an inkjet printer 3 for spraying the instructions . The conveyor belt 7 transports the instructions to the bottom of the inkjet printer 3 and pauses, and the inkjet printer 3 sprays codes on the instructions. After the inkjet coding of the instructions is completed, the conveyor belt 7 continues to run to convey the subsequent instructions to the inkjet printer 3 .

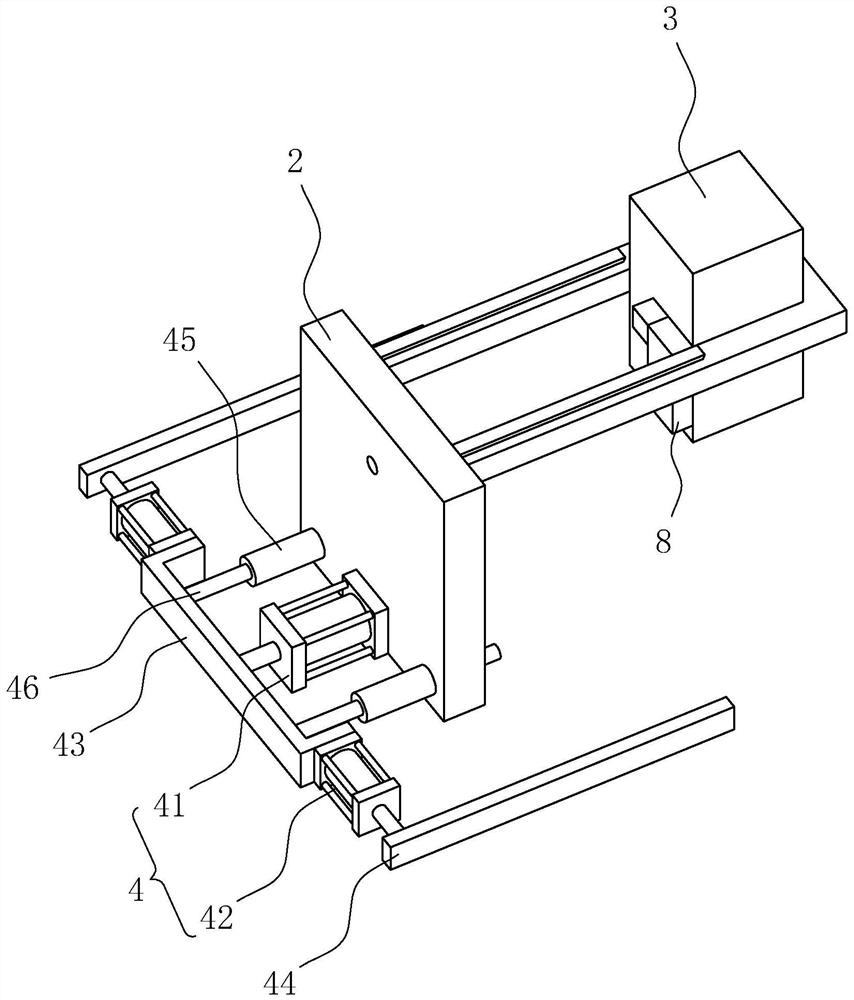

[0044] refer to figure 1 with figure 2 , the side wall of the installation frame 2 is provided with a first correction assembly 4 for correcting the position of the instructions in the conveying direction, the first correction assembly 4 includes a push-pull cylinder 41 and two clamping cylinder...

Embodiment 2

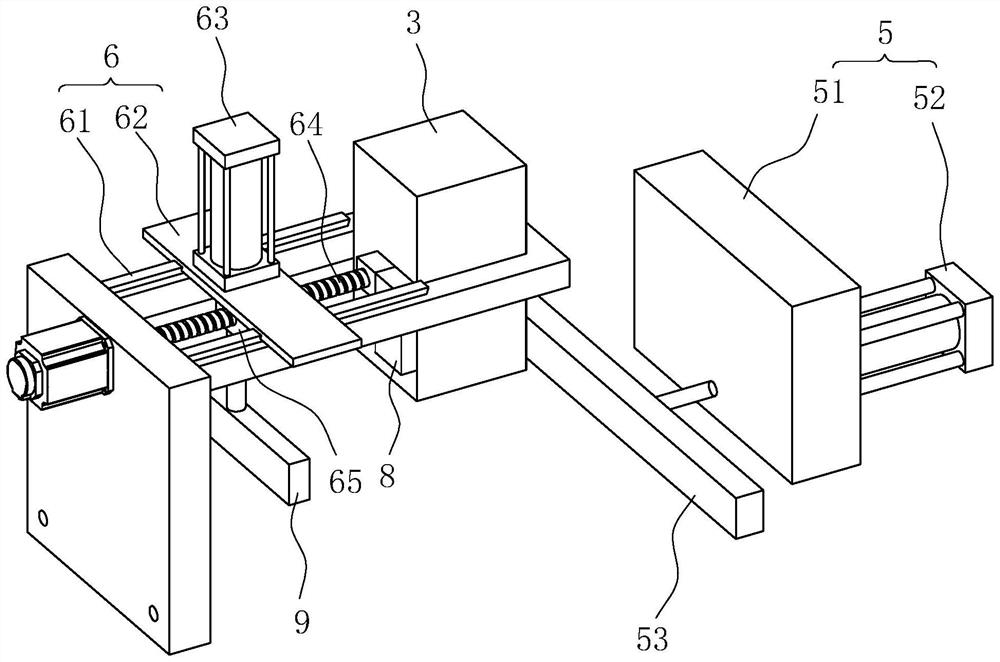

[0056] refer to Figure 4 The difference between embodiment 2 and embodiment 1 is that the detection element 8 is a sensor, specifically a photoelectric sensor, and there are two sensors spaced apart, and the two sensors are spaced at opposite corners of the coding area of the manual. The positioning point is printed on the manual corresponding to the position of the sensor, the manual is moved to the bottom of the installation frame 2, and the photoelectric sensor emits a light signal downward. If no reflected light signal is received, the positioning of the manual is accurate. If the reflected optical signal is received, it means that there is a deviation in the positioning of the instruction manual and needs to be corrected.

[0057] The implementation principle of a folded page dispensing online coding device in the embodiment of the present application is as follows: the manual is delivered to the bottom of the inkjet printer 3, the photoelectric sensor emits a light si...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com