Intelligent modular building self-mixing mortar transportation device and operation method

A transportation device and a modular technology, applied in the direction of transportation and packaging, multi-axis trolleys, trolleys, etc., can solve the problems of safe and civilized construction, messy and messy construction, decline in masonry quality, impact on workability, etc., to improve operating efficiency, Guaranteed workability and favorable effects for mass production

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

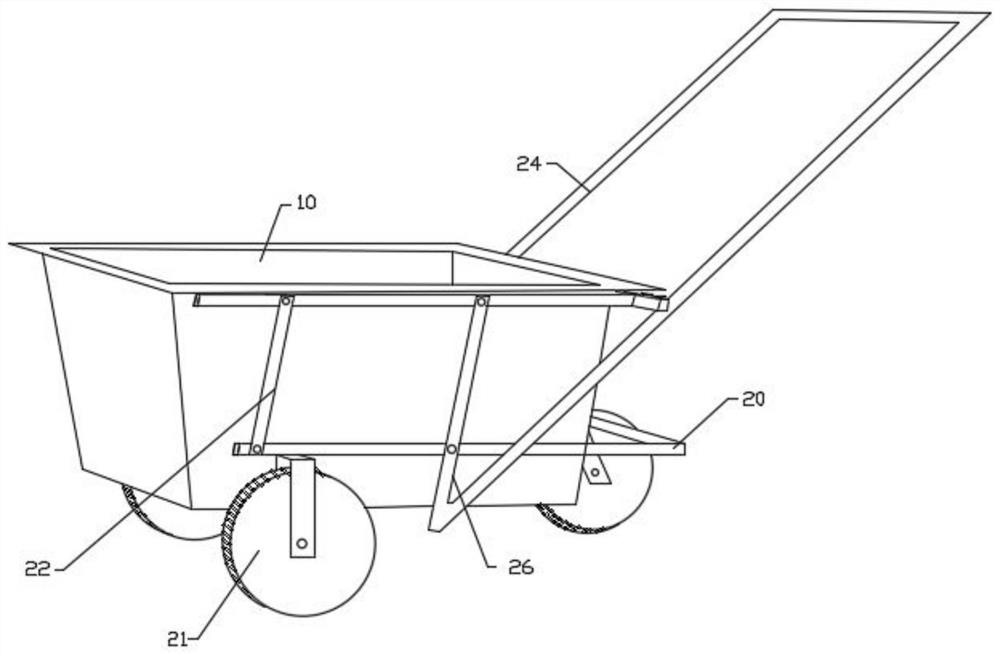

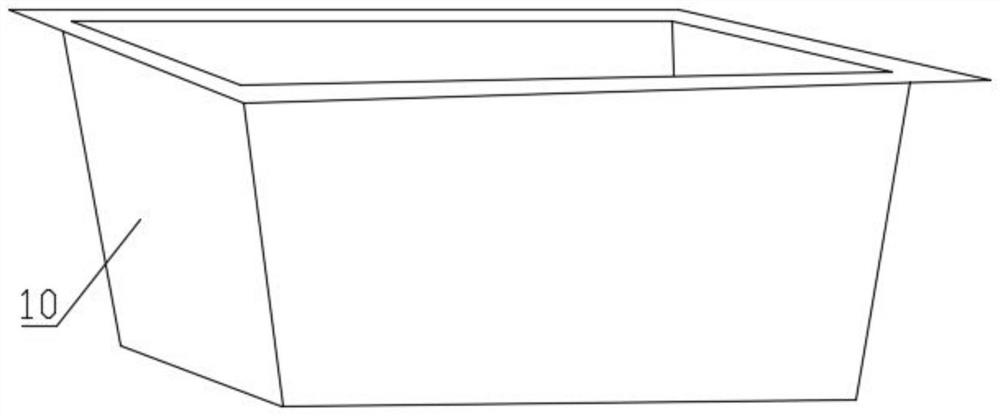

[0028] Embodiment: An intelligent modular building self-mixing mortar transportation device, including a modular box body 10, the top opening of the modular box body 10 is larger than the bottom seal, and the upper mouth of the modular box body 10 is provided with The integrally formed 80mm wide-band rib load-bearing side, the modular box 10 is made of modified polyethylene material.

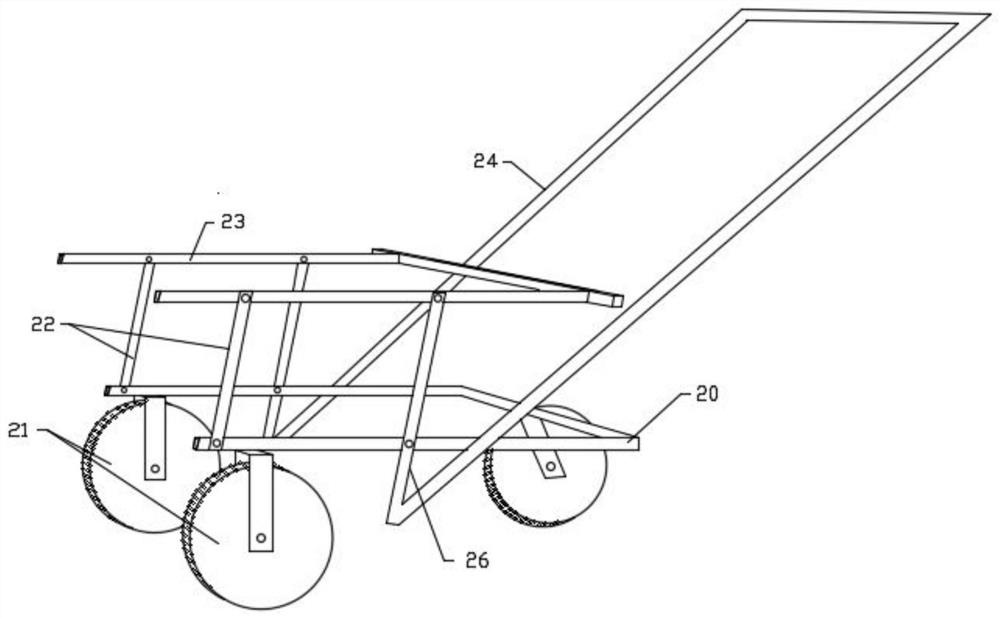

[0029] Also comprise transport body 20, the mobile mechanism that is installed on transport body 20, this mobile mechanism comprises the mobile wheel 21 that is installed on both sides of transport body 20 front part and installs rear part, and the mobile wheel 21 that is positioned at rear part is universal self-direction The locking wheel prevents the device from running off when the device is transported or moved or removed from the modular box 10 through the universal self-locking wheel on the rear side.

[0030] And the handling mechanism that moves the modular box body 10 to the top of the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com