Corrugated paperboard and corrugated carton production process

A corrugated cardboard and corrugated box technology, which is applied in the direction of paper/cardboard layered products, special paper, paper/cardboard containers, etc., can solve the problem that the inner layer of corrugated cardboard cannot play a protective role and affects the integrity of the package, cardboard Problems such as poor waterproof performance, to achieve the effect of increasing protection performance, increasing waterproof function, and increasing waterproof performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

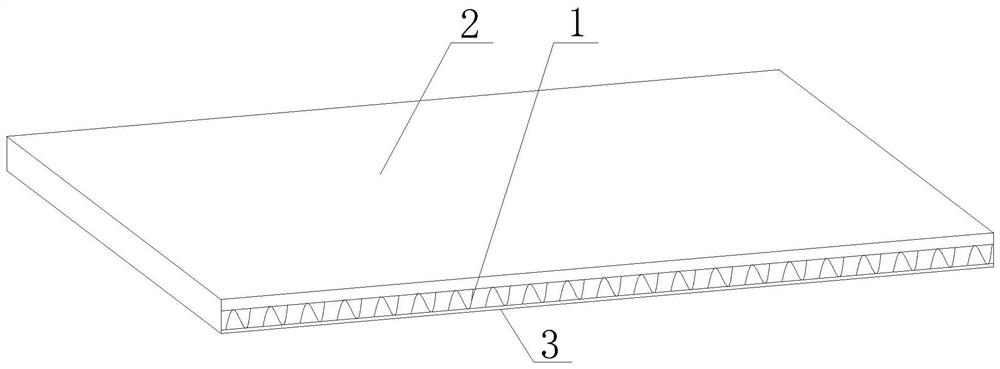

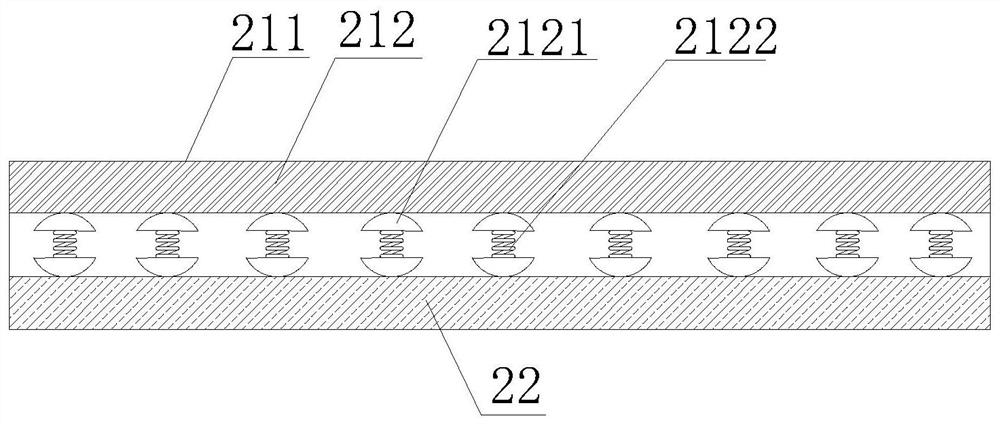

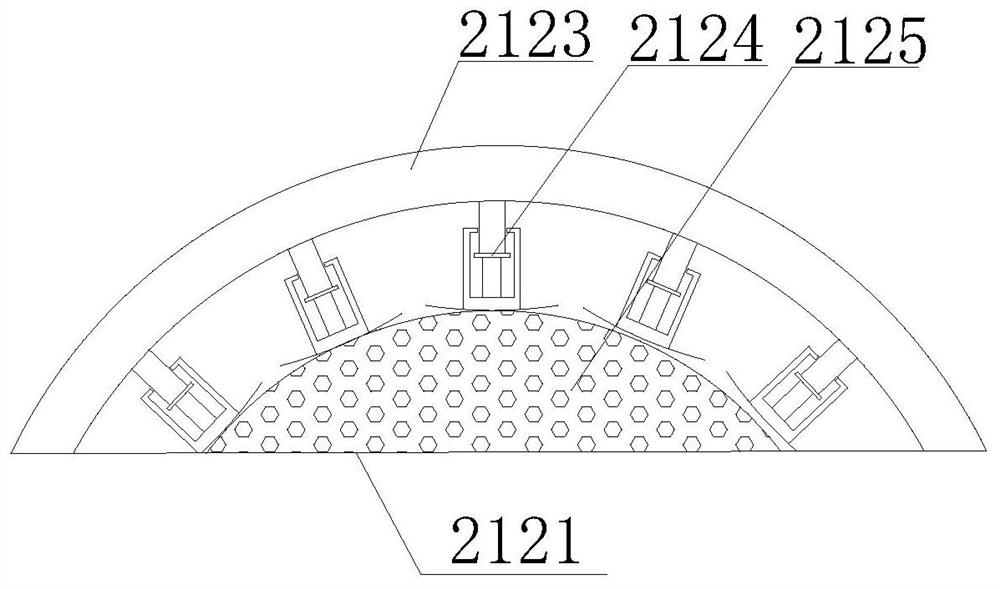

[0035] First aspect, such as Figure 1-4 As shown, the present invention provides a corrugated cardboard, comprising a cardboard body 1, an upper paper layer 2 and a bottom layer 3, the top of the cardboard body 1 is fixedly installed with the upper paper layer 2, and the bottom of the cardboard body 1 is fixedly installed with a bottom layer 3 , the inside of the upper paper layer 2 is fixedly equipped with a protective layer 21, the inside of the protective layer 21 is fixedly installed with a protective baffle 211, the bottom of the protective baffle 211 is fixedly installed with a buffer layer 212, and the bottom of the buffer layer 212 is fixedly installed with a buffer pad 213, the inside of the buffer layer 212 is fixedly installed with a pressing block 2121, the inner side of the pressing block 2121 is fixedly installed with a soft spring column 2122, the inside of the pressing block 2121 is fixedly installed with an air cushion layer 2123, and the bottom of the air cus...

Embodiment 2

[0038] Such as Figure 1-4 As shown, on the basis of Embodiment 1, the present invention provides a technical solution: preferably, the bottom of the protective layer 21 is fixedly installed with a moisture-proof layer 22, and the top of the moisture-proof layer 22 is fixedly installed with a sealing strip 221, and the sealing strip A waterproof coating 222 is fixedly installed on the bottom of the waterproof coating 221, and a waterproof paper layer 223 is fixedly installed on the bottom of the waterproof coating 222.

[0039] In this embodiment, through the tightness and adhesion of the sealant strip 221, the sealant strip 221 is connected to increase the sealability, and then cooperate with the waterproof function of the waterproof coating 222, wherein the waterproof coating 222 adopts polyurethane waterproof coating, polyurethane Waterproof coating is a single-component environment-friendly waterproof coating for liquid construction. It is based on imported polyurethane pr...

Embodiment 3

[0041] Second aspect, such as Figure 1-4 As shown, the present invention also provides a technical solution: a corrugated box production process, the corrugated box production process, including the following steps:

[0042] Step 1. Produce a cardboard body 1, an upper paper layer 2, and a bottom layer 3 of corresponding sizes according to the corrugated box;

[0043] Step 2: Cooperate with the sealing tape 221 to bond and assemble the main body 1 of the cardboard, the upper paper layer 2 and the bottom layer 3;

[0044] Step 3. Use the paper press to properly compress the cardboard, and press at different positions to make folding marks, and then fold to form the shape of the carton;

[0045] Step 4: Glue the folded junctions.

[0046]The first step includes: cutting the cardboard of the raw material with a circular pressure flat cutting device, and after cutting, cooperate with the grinder to polish the cut surface, and the second step includes: using the double-sided adh...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap