Joint construction method for hot-mix asphalt mixture and emulsified asphalt cold-recycling surface layer

A technology of asphalt mixture and construction method, which is applied to cohesive pavement paved on site, buildings, roads, etc., which can solve problems such as poor connection effect, uneven rolling of joints, and differences in connection methods, so as to improve connection quality , the effect of improving the overall performance

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0022] A joint construction method between hot-mix asphalt mixture and emulsified asphalt cold recycled surface course, comprising the following steps:

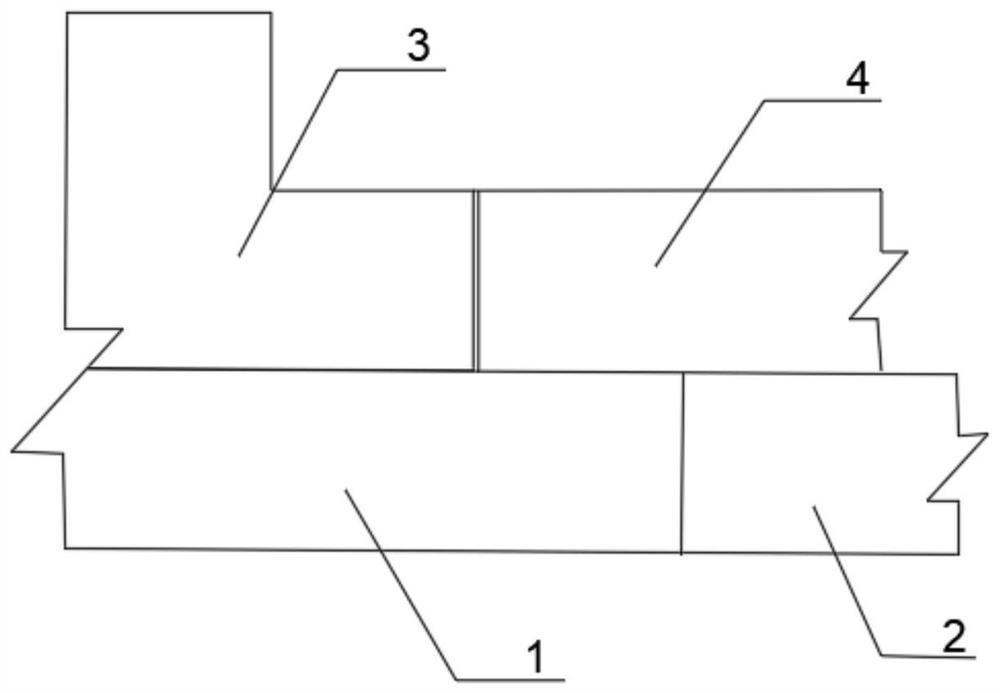

[0023] (1) milling the old pavement layer 3, making the edge distance of the old pavement layer 3 and the edge distance of the corresponding old road base 1 be 15cm, and cleaning and reclaiming the asphalt mixture for subsequent use;

[0024] (2) Lay the new road base 2 next to the old road base 1, so that the top surface of the new road base 2 and the top surface of the old road base 1 are on the same level, and after the maintenance of the new road base 2 is completed, lay it next to the old road surface layer 3 The asphalt cold regeneration surface layer 4; the new road base 2 contains the following raw materials in parts by weight: 25 parts by weight of stone chips with a particle size of less than 5 mm, 10 parts by weight of crushed stones with a particle size of 5-10 mm, and 10 parts by weight of crushed stones with a pa...

Embodiment 2

[0027] A joint construction method between hot-mix asphalt mixture and emulsified asphalt cold recycled surface course, comprising the following steps:

[0028] (1) milling old pavement layer 3, the edge distance that makes the edge of old pavement layer 3 and its corresponding old road base 1 be 25cm, and clean up and reclaim asphalt mixture for subsequent use;

[0029] (2) Lay the new road base 2 next to the old road base 1, so that the top surface of the new road base 2 and the top surface of the old road base 1 are on the same level, and after the maintenance of the new road base 2 is completed, lay it next to the old road surface layer 3 The asphalt cold regeneration surface layer 4; the new road base 2 contains the following raw materials in parts by weight: 28 parts by weight of stone chips with a particle size of less than 5mm, 12 parts by weight of crushed stones with a particle size of 5-10mm, and 12 parts by weight of gravel with a particle size of 10-20mm 35 parts ...

Embodiment 3

[0032] A joint construction method between hot-mix asphalt mixture and emulsified asphalt cold recycled surface course, comprising the following steps:

[0033] (1) milling old pavement layer 3, make the edge distance of the edge of old pavement layer 3 and its corresponding old road base 1 be 30cm, and clean up and reclaim the asphalt mixture for subsequent use;

[0034] (2) Lay the new road base 2 next to the old road base 1, so that the top surface of the new road base 2 and the top surface of the old road base 1 are on the same level, and after the maintenance of the new road base 2 is completed, lay it next to the old road surface layer 3 The asphalt cold regeneration surface layer 4; the new road base layer 2 contains the following raw materials in parts by weight: 32 parts by weight of stone chips with a particle size of less than 5 mm, 15 parts by weight of gravel with a particle size of 5-10 mm, and 15 parts by weight of gravel with a particle size of 10-20 mm 40 part...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

| Particle size | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com