Hydraulic motor detection system and method

A technology of hydraulic motor and detection system, which is applied in the test of fluid pressure actuation system, fluid pressure actuation device, mechanical equipment, etc., can solve the problems of large influence of test workers' operation, increase of working hours and labor costs, etc., and reduce human resources. Demand and labor costs, the effect of improving detection accuracy and improving production efficiency

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0025] The specific implementation manners of the present invention will be further described in detail below in conjunction with the accompanying drawings and embodiments. The following examples are used to illustrate the present invention, but are not intended to limit the scope of the present invention.

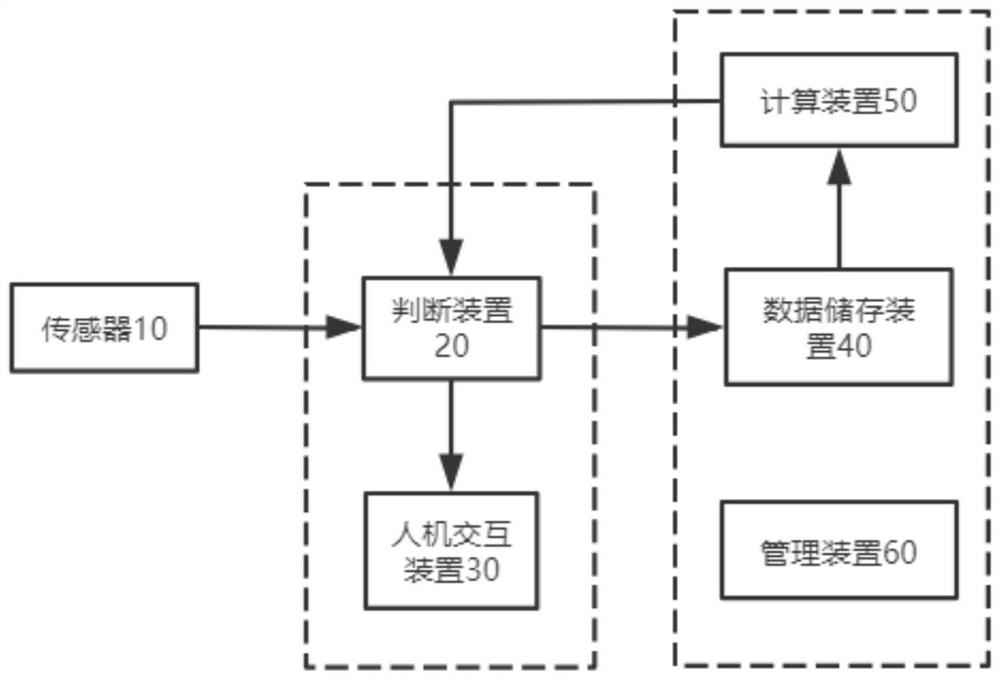

[0026] Please refer to figure 1 According to an embodiment of the present invention, a hydraulic motor detection system includes a sensor 10 , a judging device 20 , a human-computer interaction device 30 , a data storage device 40 , a computing device 50 and a management device 60 . The hydraulic motor (not shown) after the production line enters the detection link, and simulates the normal working condition, and the sensor 10 obtains the test process parameter data of the hydraulic motor under test. In this embodiment, the sensor 10 includes a pressure sensor, a noise sensor, an oil temperature sensor, a flow sensor, and a vibration sensor. In other embodiments, the sen...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com