Laser searchlighting device for metal trace detection

A trace and laser technology, used in measuring devices, optical testing of flaws/defects, material analysis by optical means, etc. The effect of easy maintenance and increased shooting range

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0057] The following description serves to disclose the present invention to enable those skilled in the art to carry out the present invention. The preferred embodiments described below are only examples, and those skilled in the art can devise other obvious variations.

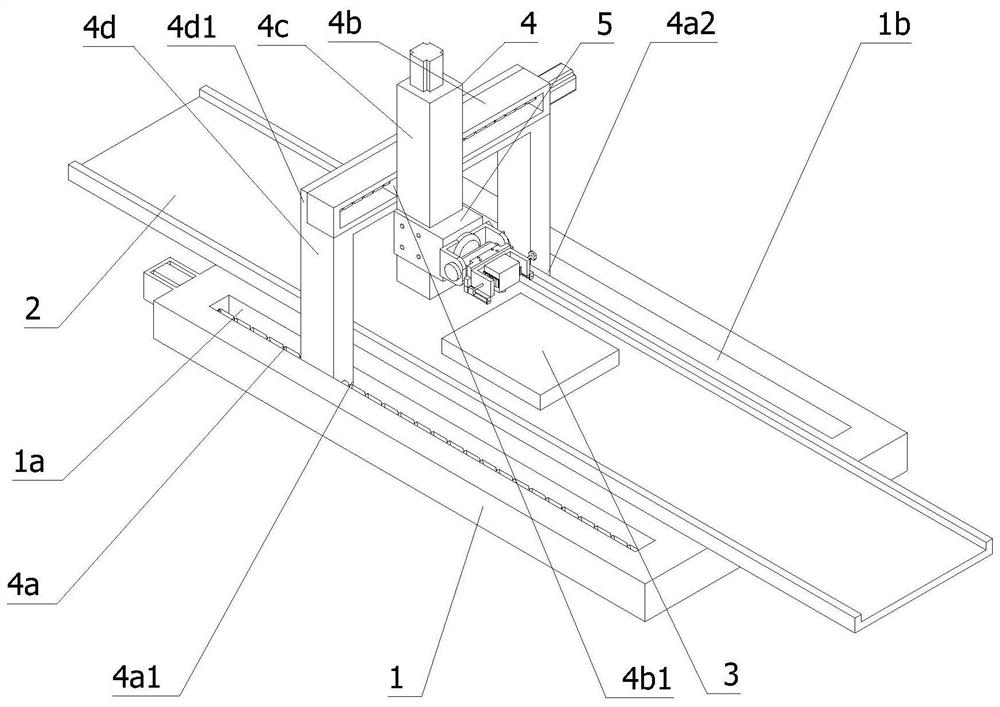

[0058] In order to solve the technical problem of how to increase the shooting range of the camera module during the detection process, refer to Figure 1-10 A laser search device for metal trace detection is shown, comprising,

[0059] Workbench 1;

[0060] Conveyor 2, part of conveyor 2 is set above workbench 1;

[0061] The workpiece 3 is set on the conveyor 2;

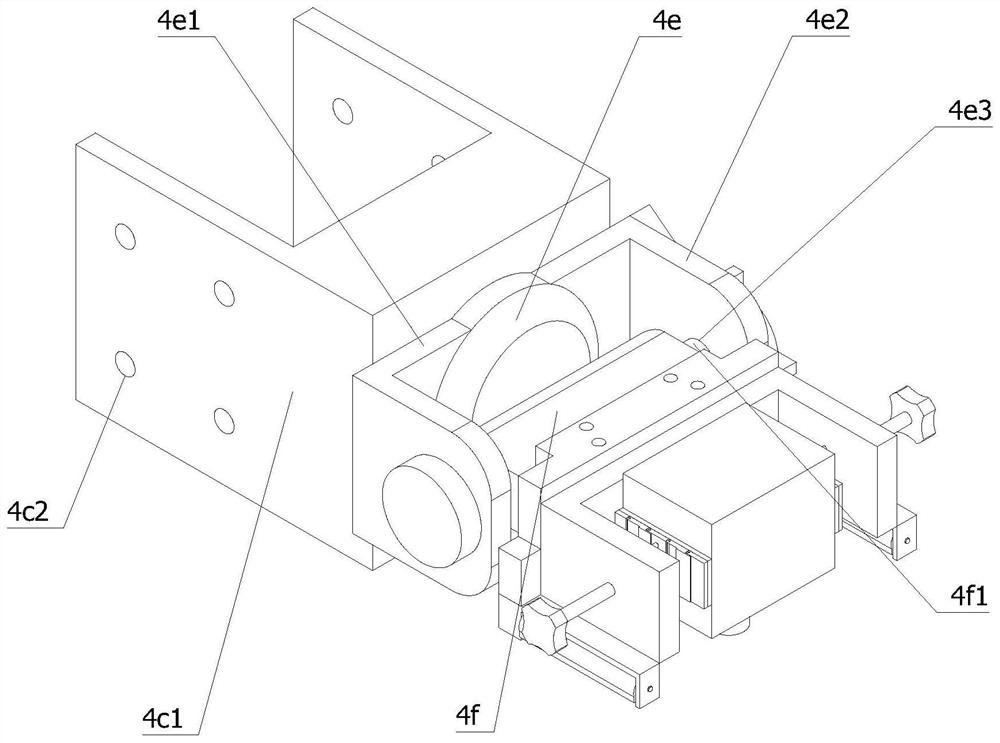

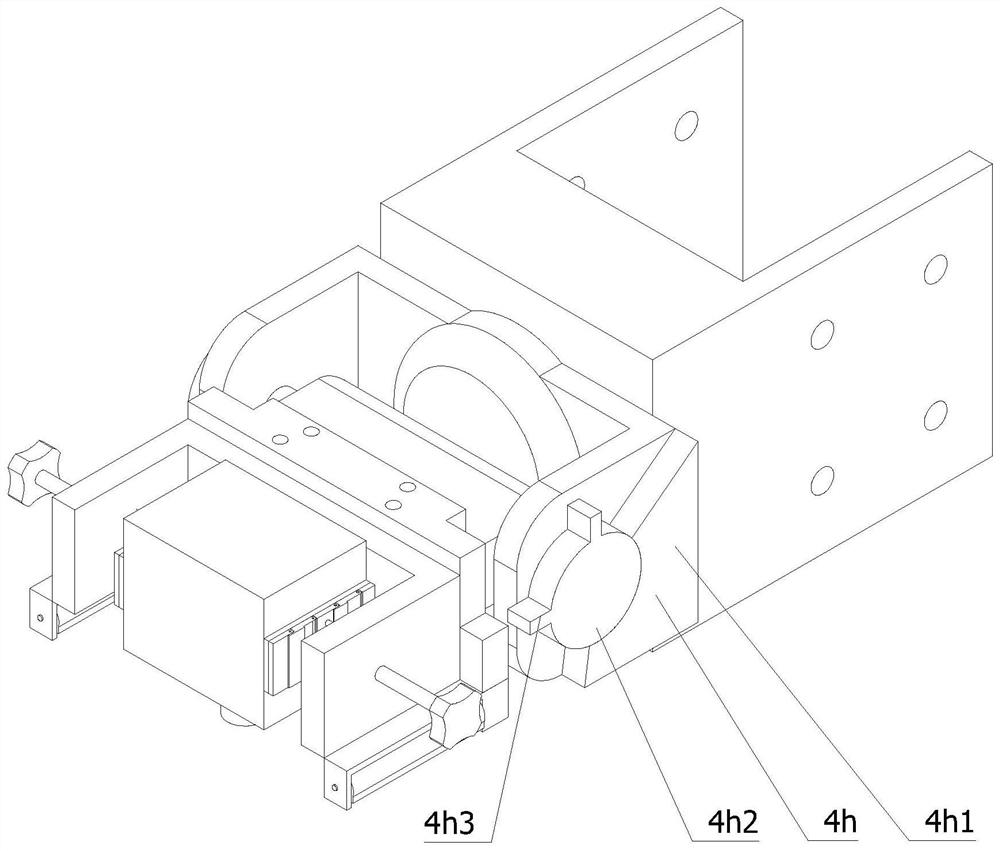

[0062] The five-axis linkage mechanical arm 4 is set on the workbench 1;

[0063] One end of the camera assembly 5b on the five-axis linkage mechanical arm 4 is also provided with a first fixing mechanism 5, the first fixing mechanism 5 includes,

[0064] The first support 5a is arranged on the five-axis linkage mechanical arm 4 and is locat...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com