Photovoltaic panel frame assembling machine capable of preventing glue from overflow drain

A photovoltaic panel and assembly machine technology, applied in photovoltaic power generation, photovoltaic modules, electrical components, etc., can solve the problems of unavoidable glue overflow and inability to install the upper frame of photovoltaic panels, and achieve the effect of preventing excess glue overflow and improving quality.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

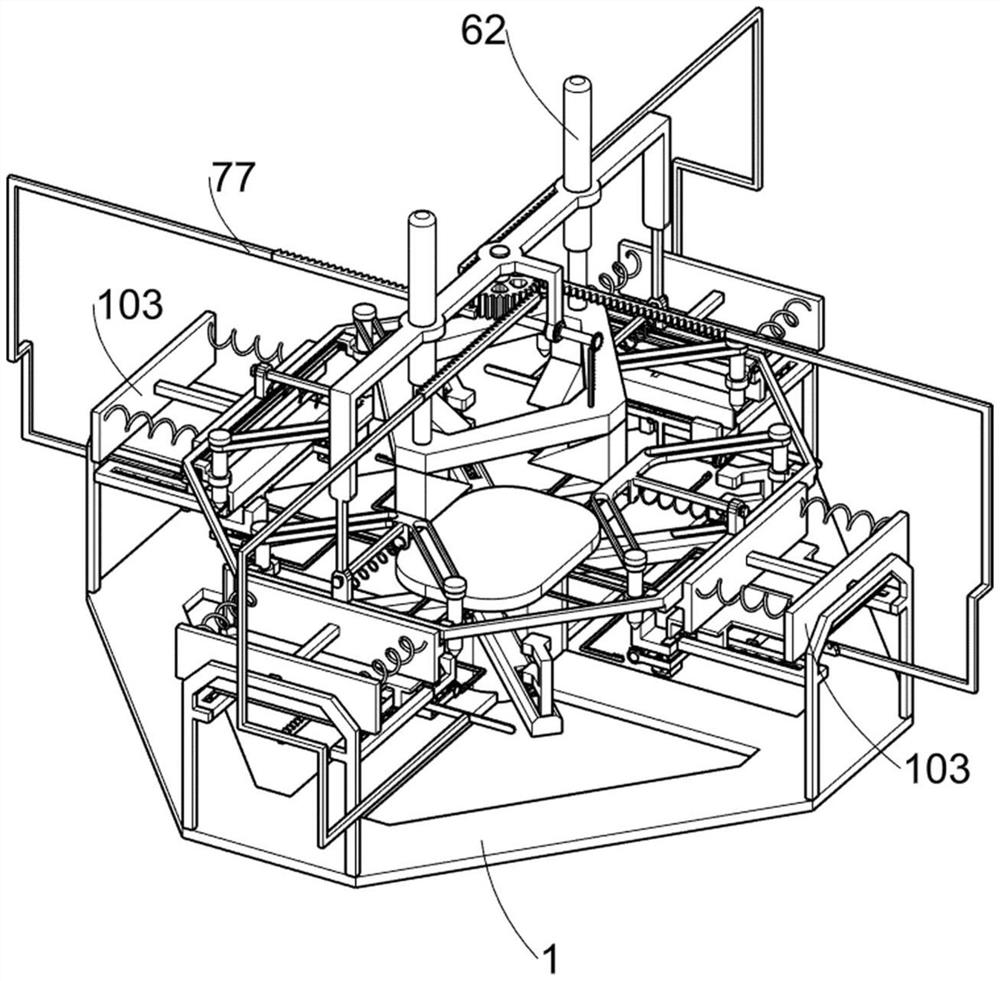

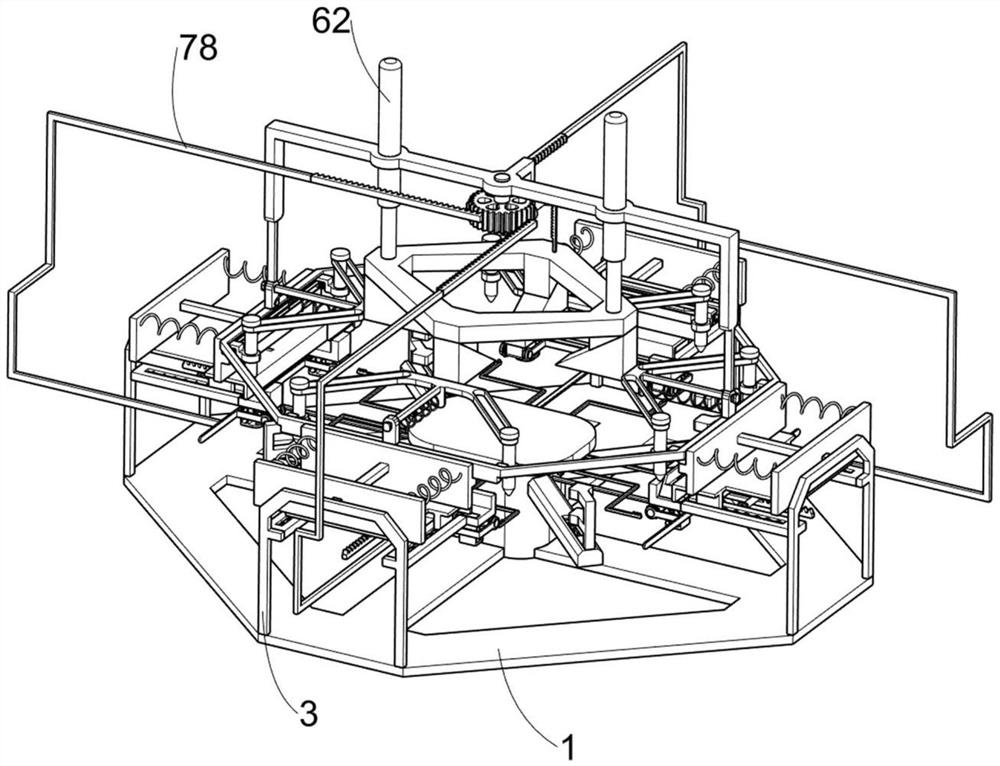

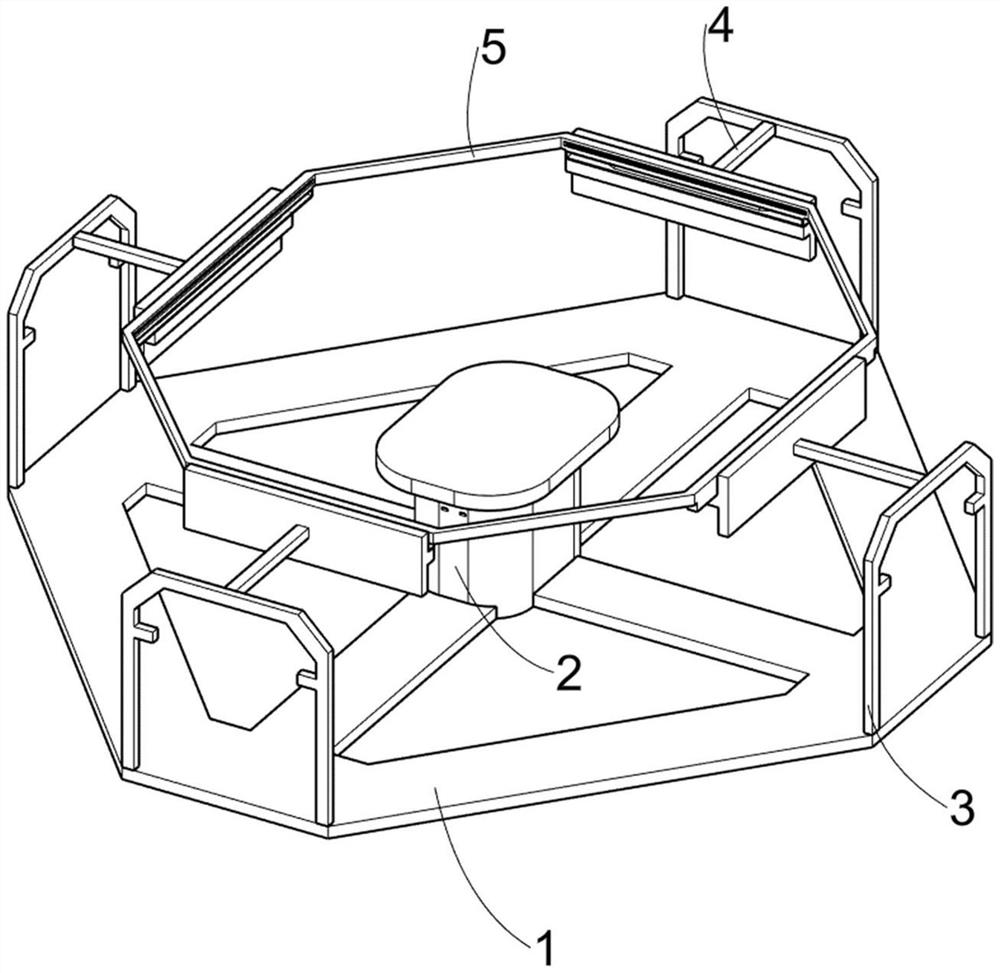

[0030] A photovoltaic panel frame assembly machine to prevent glue leakage, such as Figure 1-12 As shown, it includes a four-corner base 1, a slotted pile 2, a special-shaped support door frame 3, a special-shaped connection block 4, a slotted slide rail frame 5, a downward pressure reciprocating extrusion mechanism 6, a surrounding closing mechanism 7, and a rotating assembly mechanism 8 And the reinforcement mechanism 9, the top of the four-corner base 1 is connected with a slotted pile 2, the top of the four-corner base 1 is connected with two pairs of special-shaped support gantry 3, and the special-shaped support gantry 3 is connected with a special-shaped connection block 4, one of four special-shaped connection blocks 4 A slotted slide rail frame 5 is jointly connected between the slotted slide rail frames 5, and four pairs of slide grooves are arranged on the slotted slide rail frame 5. After extruding the glue onto the frame, the surrounding closing mechanism 7 is se...

Embodiment 2

[0042] On the basis of Example 1, such as Figure 11-12 As shown, a pushing mechanism 10 is also included, and the pushing mechanism 10 is arranged on the special-shaped support door frame 3. The pushing mechanism 10 is used to push out the frame. The pushing mechanism 10 includes an N-shaped slotting frame 101, a blanking plate 102, push plate 103, second tension spring 104, fourth return spring 105, fixed block 106, rotating shaft two 107, third gear 108, second rack 109 and third rack 110, on the special-shaped support door frame 3 Connected with an N-shaped slotting frame 101, the N-shaped slotting frame 101 is slidably connected with a blanking plate 102, the blanking plate 102 is in contact with the slotted swing frame 87, the blanking plate 102 is in contact with the wedge-shaped block 88, and the special-shaped connection A push plate 103 is slidably connected on the block 4, and the push plate 103 is in contact with the blanking plate 102. A pair of second tension spr...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com