Active safety protection system and method for energy storage battery station

An active safety, energy storage battery technology, applied in secondary batteries, circuits, electrical components, etc., can solve the problems of inability to monitor abnormal temperature, difficult to analyze and determine the concentration of multi-component mixed gas, high technical cost and difficult to popularize, etc. The effect of active safety protection

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

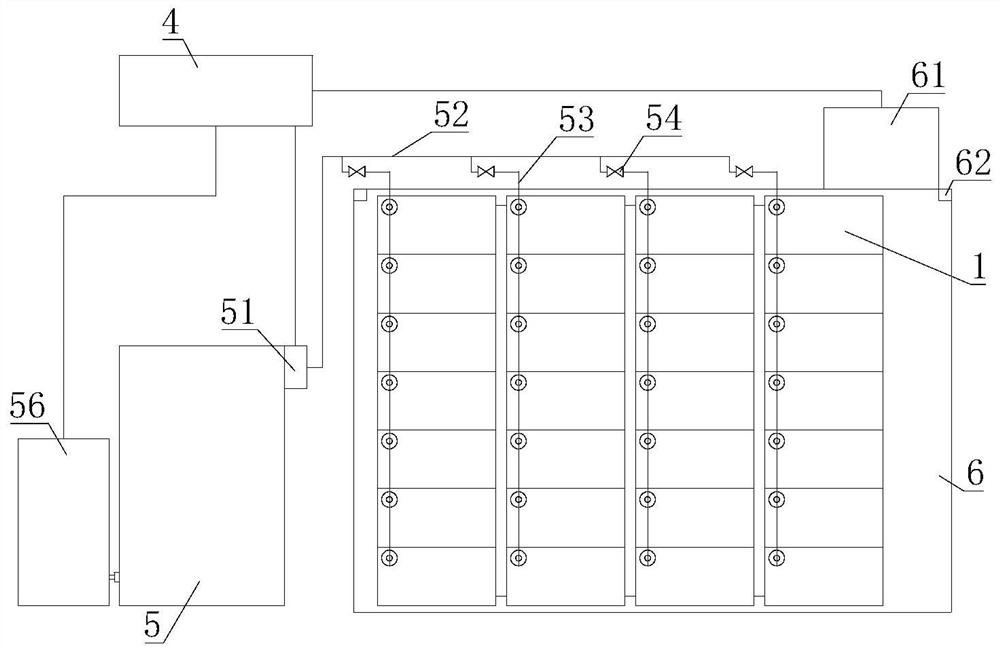

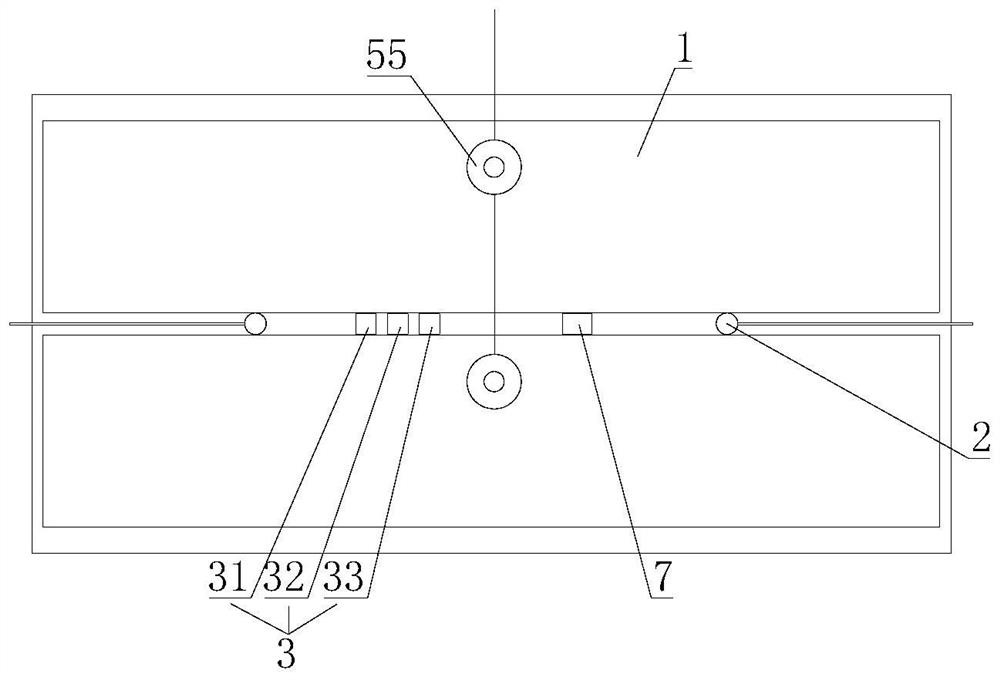

[0040] Such as figure 1 and figure 2 As shown, the active safety protection system for energy storage battery stations in this embodiment includes several temperature sensors 2 and several gas concentration detectors 3 installed between adjacent lithium battery modules 1; it also includes a control device 4, several The lithium battery module 1, some temperature sensors 2 and some gas concentration detectors 3 are all electrically connected to the control device 4; and a fire extinguishing agent storage tank 5 is also included, and a pump group 51 is connected to the fire extinguishing agent storage tank 5, and the outlet of the pump group 51 A fire extinguishing agent delivery pipeline 52 is connected, and a number of branch pipelines 53 are connected to the fire extinguishing agent delivery pipeline 52. A solenoid valve 54 is installed on the branch pipeline 53, and a nozzle 55 is installed on the lithium battery module 1, and the nozzle 55 extends into the lithium battery ...

Embodiment 2

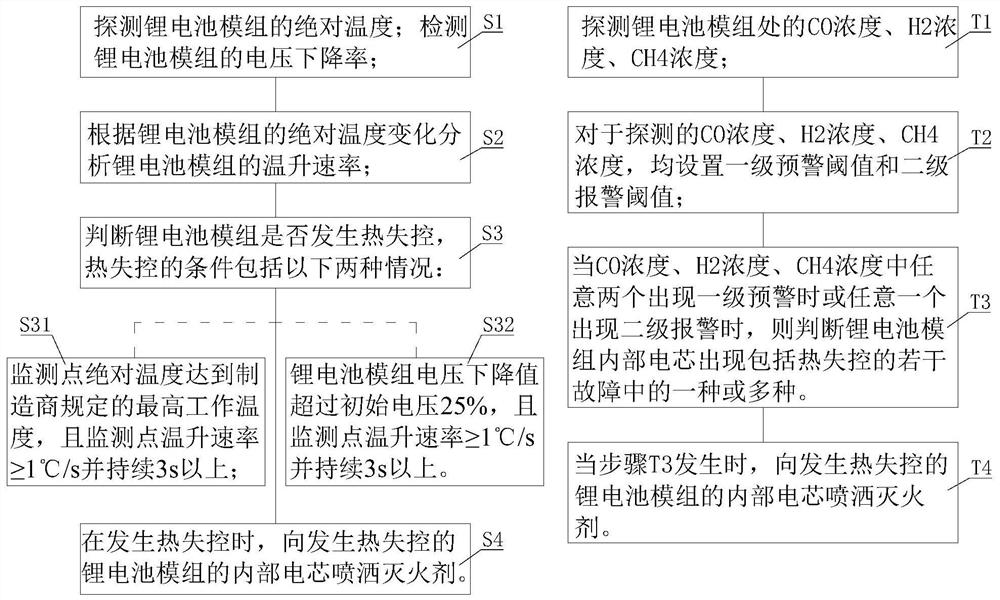

[0052] Such as Figure 1 ~ Figure 3 As shown, the active safety protection method for energy storage battery stations in this embodiment includes the following steps:

[0053] S1: Detect the absolute temperature of the lithium battery module 1; detect the voltage drop rate of the lithium battery module 1;

[0054] S2: Analyze the temperature rise rate of the lithium battery module 1 according to the absolute temperature change of the lithium battery module 1;

[0055] S3: Determine whether thermal runaway occurs in the lithium battery module 1, where the conditions for thermal runaway include the following two situations:

[0056] S31: The absolute temperature of the monitoring point reaches the maximum working temperature specified by the manufacturer, and the temperature rise rate of the monitoring point is ≥1°C / s and lasts for more than 3s;

[0057] S32: The voltage drop of lithium battery module 1 exceeds 25% of the initial voltage, and the temperature rise rate of the m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com