Graphene battery combination support based on guide rail movement and combination method thereof

A graphene and combined bracket technology, applied in battery pack parts, secondary batteries, battery covers/end covers, etc., can solve problems such as large deviation angles, melting and damage of parts, and many human-controlled factors, and achieve improved performance. The speed of heat dissipation and the effect of reducing damage

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

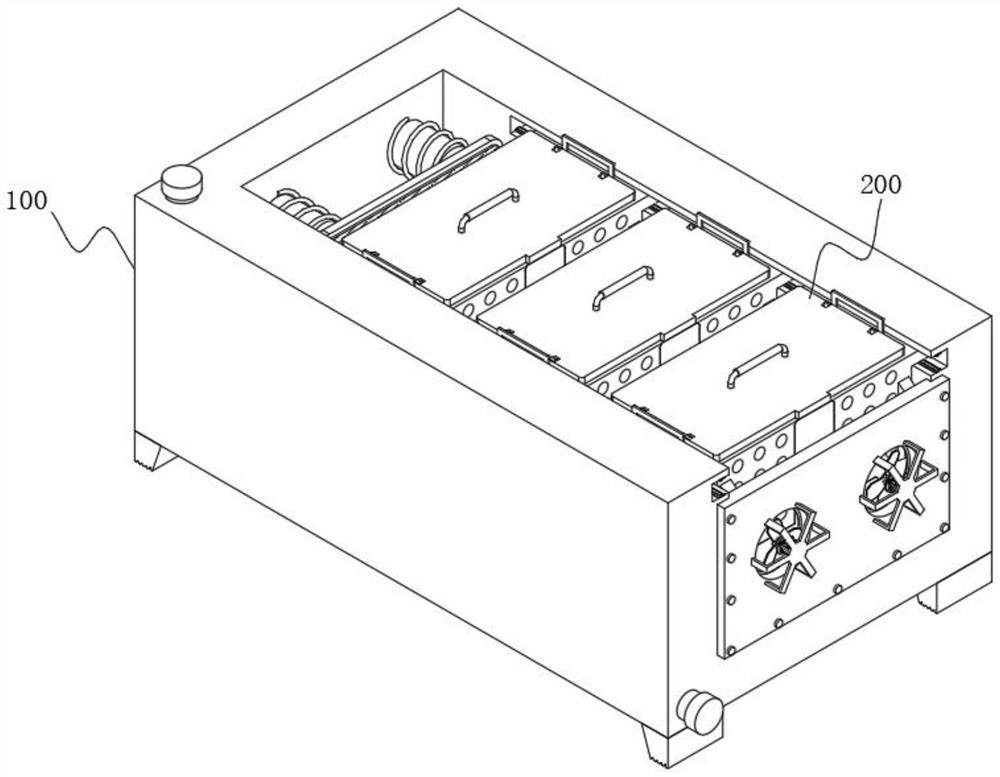

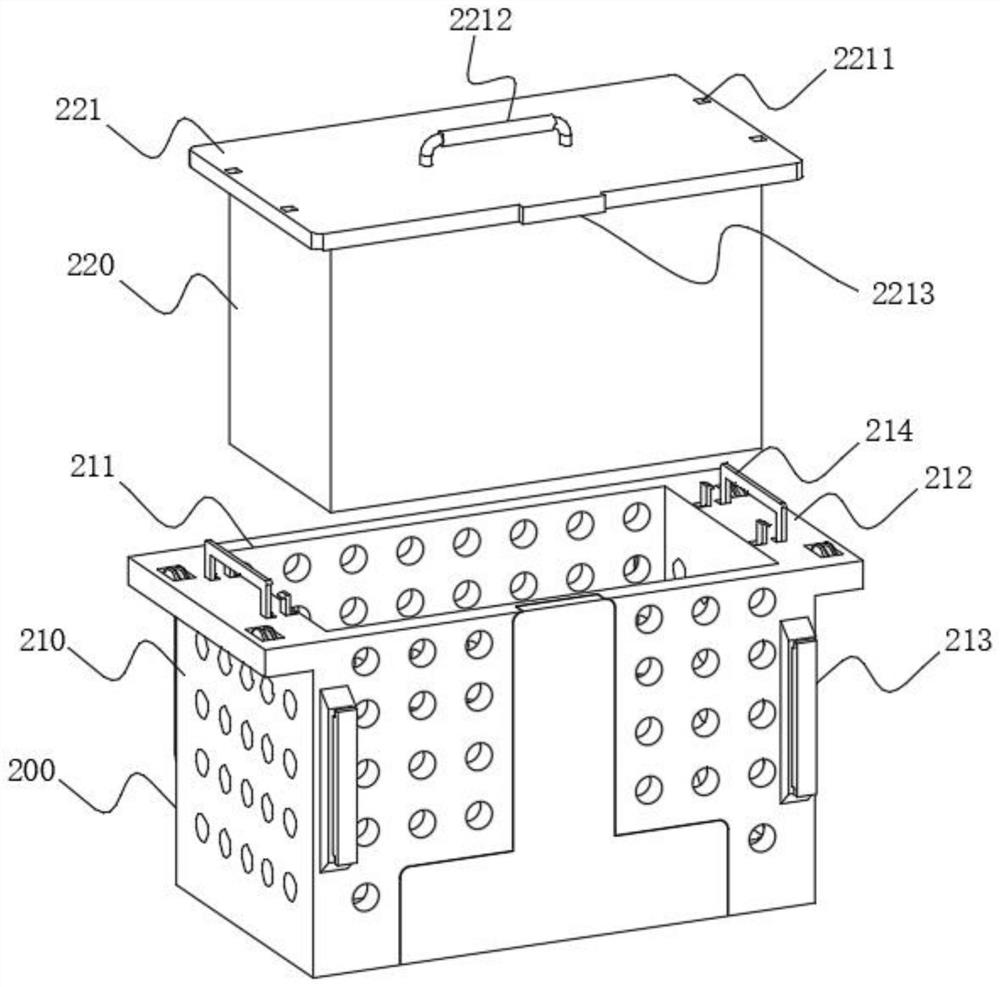

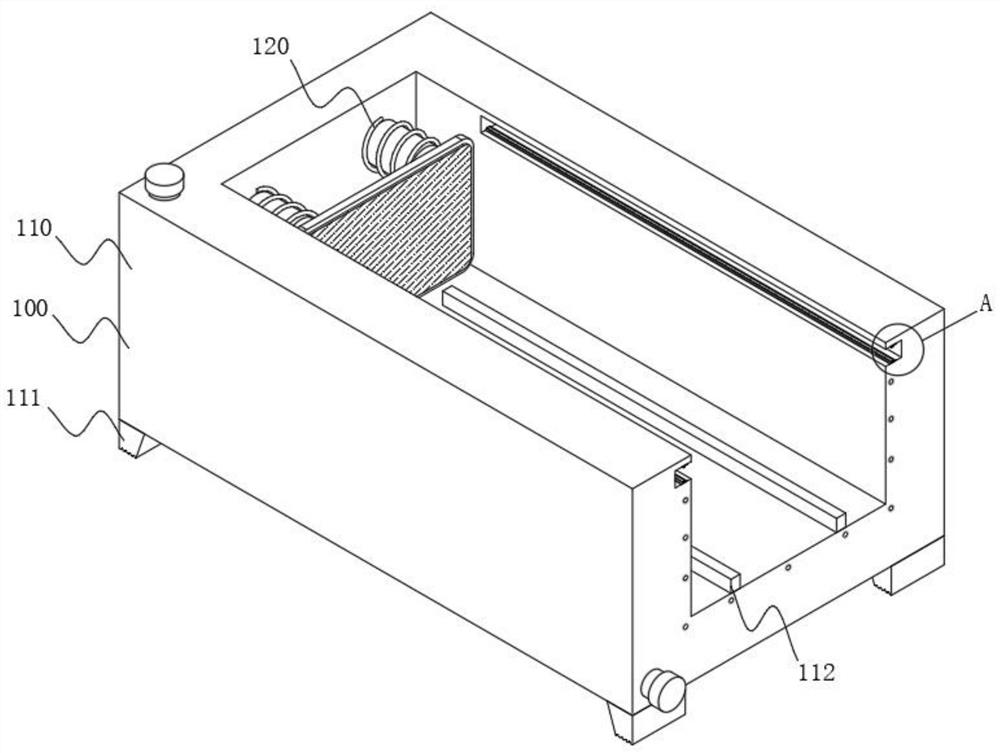

[0077] see Figure 1-Figure 17 As shown, one of the purposes of this embodiment is to provide a graphene battery assembly support based on guide rail movement, including a guide mechanism 100 and a plurality of combination mechanisms 200 arranged inside the guide mechanism 100, the guide mechanism 100 at least includes a guide seat 110, The guide seat 110 is a "U"-shaped structure, thereby forming a cavity with a hollowed out top to provide a moving space for the combined outer box 210. The top of the opposite side of the guide seat 110 two side walls is provided with a guide groove 113, and the top of the guide groove 113 Both the bottom and the bottom are provided with guide rails 1131;

[0078] Limiting device 120, the limiting device 120 is arranged on the rear side inside the guide seat 110, the limiting device 120 includes a sealing slide bar 122, the front end of the sealing sliding bar 122 is provided with a support plate 1221, and the front side of the support plate 1...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com