Auxiliary positioning device for welding body and point of end mill

An auxiliary positioning and end milling technology, applied in the field of machinery, can solve the problems that the position of the high-frequency induction coil cannot be kept consistent, the mutual position of the tool tip and the tool body cannot be kept consistent, and the quality of the finished product is different, so as to improve the welding quality. Quality, reduce labor intensity, ensure the effect of technical precision

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

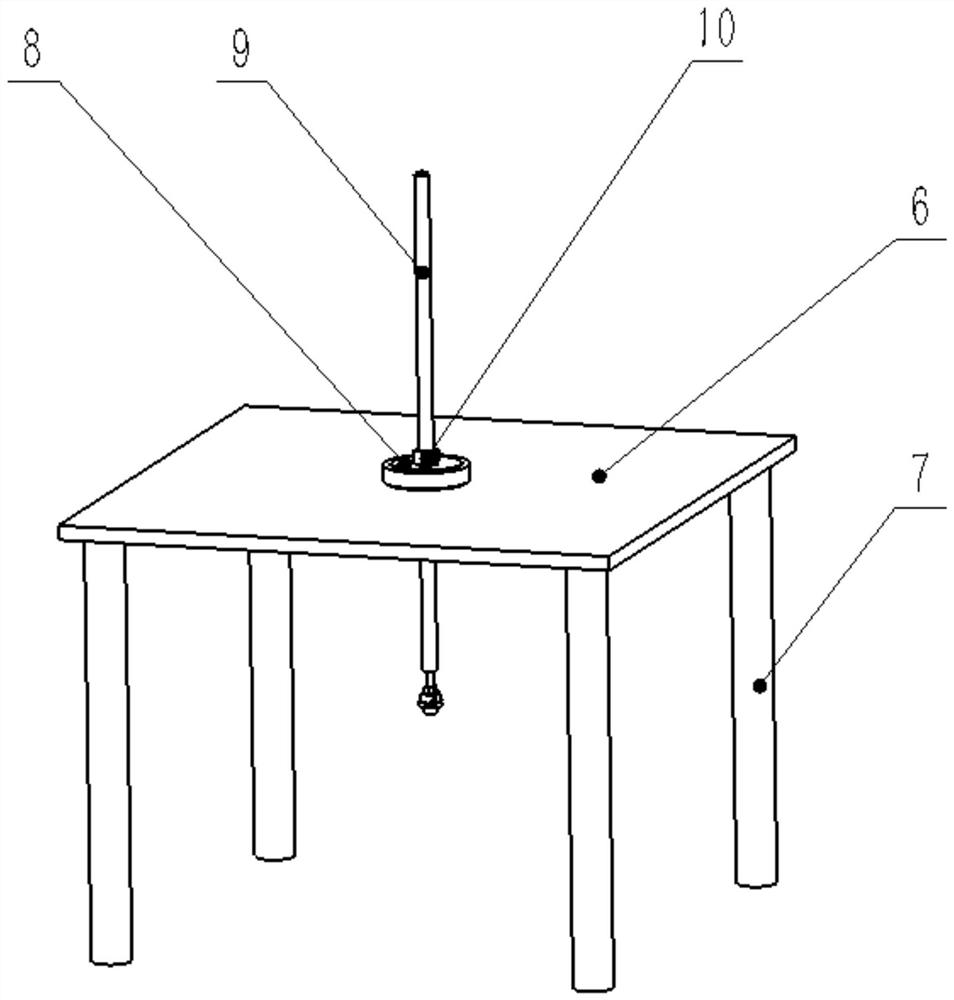

[0013] The auxiliary positioning device of the present invention includes a positioning frame inlaid with the knife body and the knife tip before welding, a clamping member after the knife body and the knife tip are inlaid, and an assembly component bracket during welding,

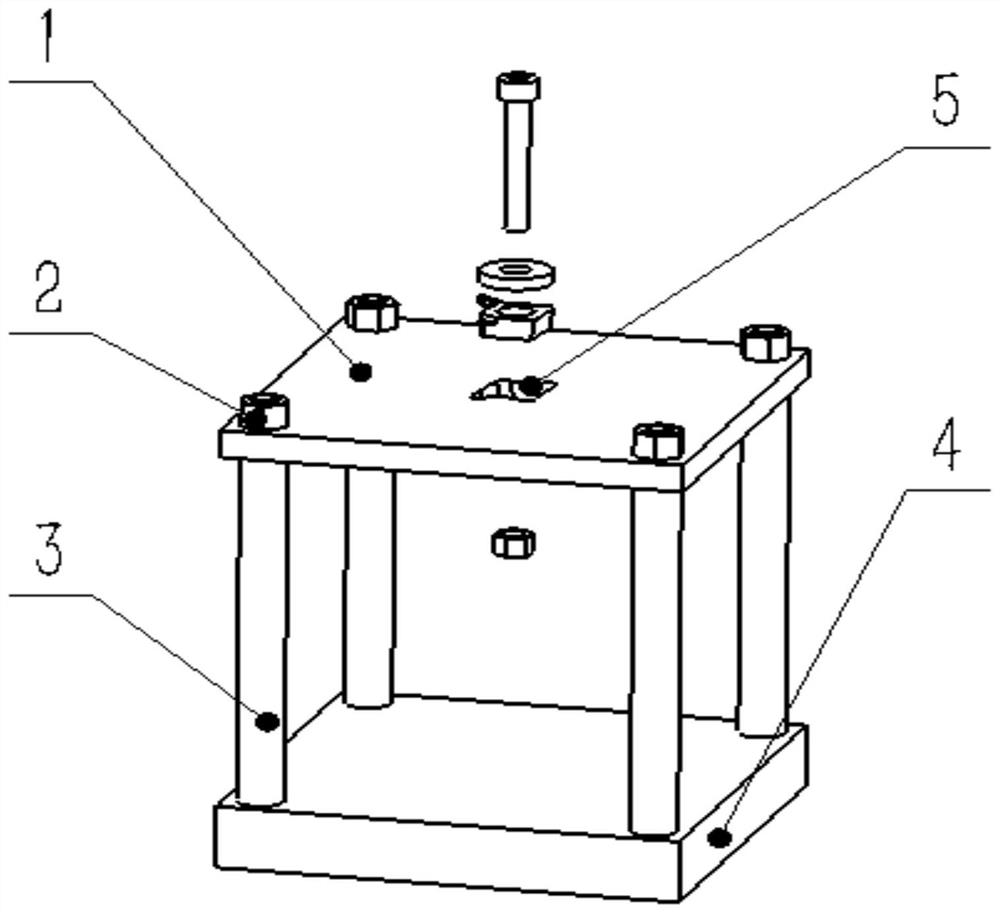

[0014] refer to figure 1 , the inlaid positioning frame is composed of the upper plate 1 carrying the knife block, the base plate 4 of the stable overall positioning frame, the column 3 between the upper plate and the base plate, and the lower end of the column 2 is connected with the base plate 4 through threads, and the column 3. The upper end passes through the upper plate 1 and is fastened with the upper plate 1 with the locking nut 2. The upper plate 1 has a positioning groove 5 matching the knife block, and the groove bottom of the positioning groove has an assembled knife body, a knife Pointed ceramic screw and nut through hole.

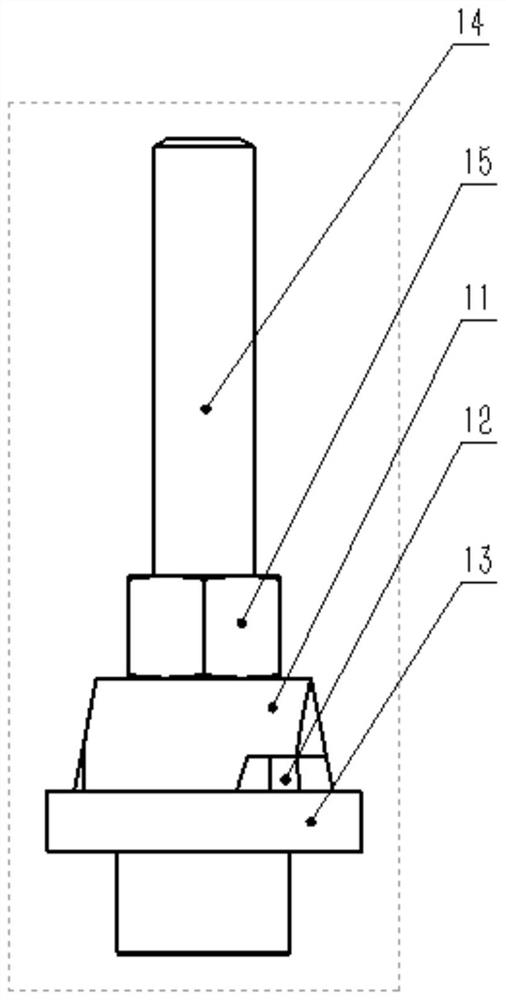

[0015] refer to figure 2 The clamping member after the cutter body...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com