High-safety power supply box

A high-safety, power supply box technology, applied in the field of power supply boxes, can solve the problems of overheating damage to the power supply box, poor heat dissipation effect, affecting safe use, etc., to achieve the effect of enhancing the cooling effect, improving the heat dissipation effect, and avoiding overheating damage.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

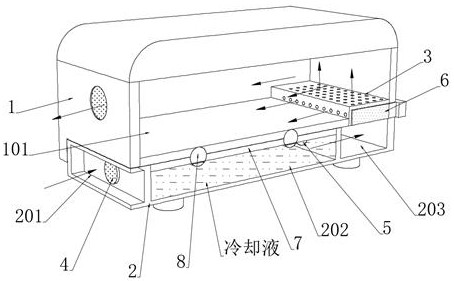

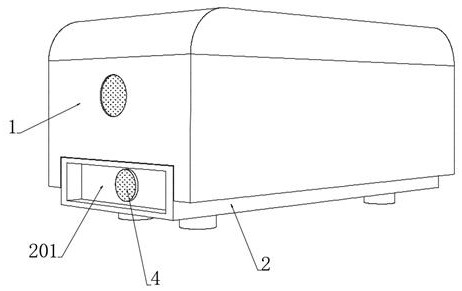

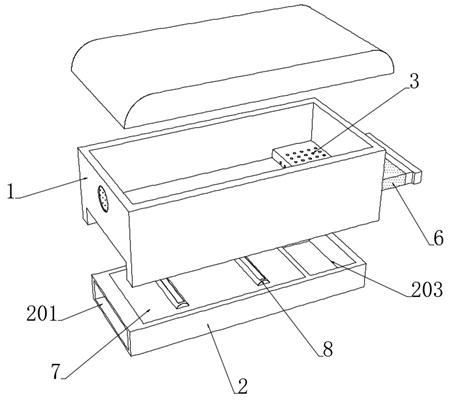

[0042] see Figure 1-6 , a high-safety power supply box, including a power supply box 1, a water cooling box 2 is embedded in the bottom of the power supply box 1, a connecting cavity corresponding to the position of the water cooling box 2 is opened at the bottom of the power supply box 1, and a connecting cavity corresponding to the position of the water cooling box 2 is opened at the bottom of the power supply box 1. The connecting cavity is connected to the hollow cavity, and the hollow cavity is embedded with a flow-through heat-conducting element, which includes a heat-conducting plate 101 and a dispersing wind plate 3 connected to each other. Chamber 202, the left and right ends of the water cooling box 2 are provided with an air induction chamber 201 and an overflow chamber 203 communicating with the water cooling chamber 202 respectively, and a one-way inlet chamber 201 and an overflow chamber 203 are respectively provided at the places where the air induction chamber ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com