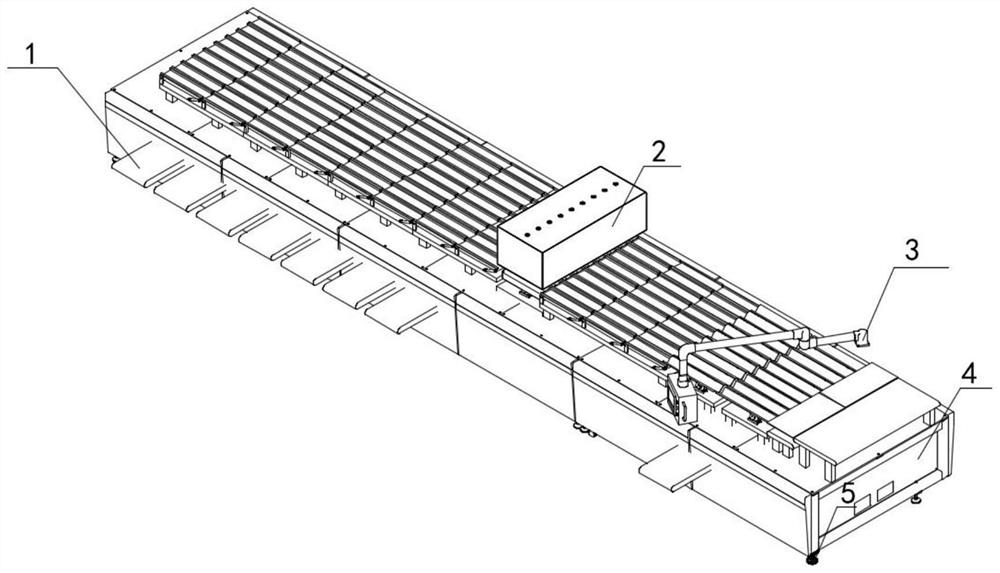

Classified screening assembly line

A grading screening and assembly line technology, applied in the seafood grading and screening industry, fruit and vegetable fields, can solve the problems of information misjudgment, high maintenance cost, single feed channel, etc., to achieve stable and reliable detection, improve detection efficiency and reliability.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment example 1

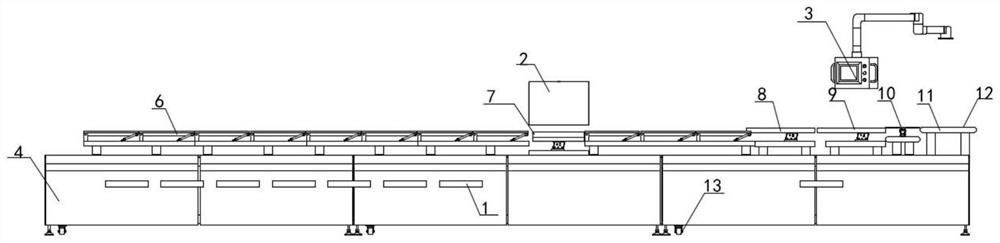

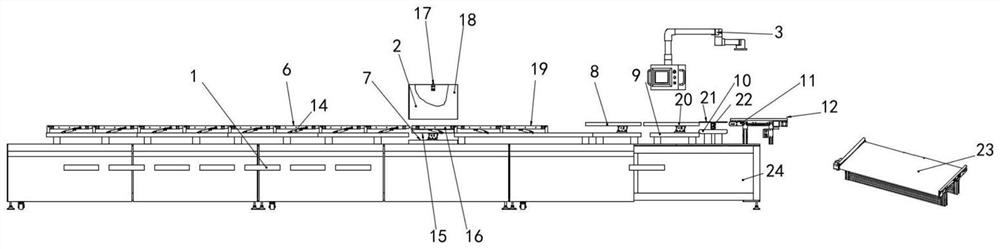

[0047] Such as figure 2As shown, the present embodiment provides a grading and screening assembly line, which is characterized in that: the modular feeding device 6 adopts a standard part and is modularly arranged, and the modular feeding device arranged on one side of the flipping conveying device 7 6 is composed of a belt conveyor 23, the driving shaft of the belt conveyor 23 is connected to the modular frame 4 through a bearing (standard part, not marked in the figure) to form a hinge structure, and the gear shaft of the belt conveyor 23 is connected through a gear (standard part , not marked in the figure) is connected to the motor gear shaft of the modular delivery device 6, the middle part of the belt conveyor 23 is connected to one end of the cylinder 14 to form a hinge structure, and the other end of the cylinder 14 is connected to the modular frame 4 Form a hinge structure.

Embodiment example 2

[0049] Such as Figure 5 As shown, the present embodiment provides a classification and screening assembly line, which is characterized in that: the chain plate conveying device 42 is composed of multiple groups of chain plate delivery mechanisms 25 connected in series, the upper side of the modular frame is provided with a track 40, and the chain plate Plate throwing mechanism 25 is arranged on the upper side of track 40, and described chain plate throwing mechanism 25 is formed into a circle by bracket a28 and chain drive 39 in series, is ring-shaped setting, and described chain drive 39 also can adopt belt drive; The bracket a28 at the position of the chain plate conveying device is connected to the turning plate 30 through the first pin shaft 29, and the turning plate 30 is connected to the upper connecting rod 32 through the second pin shaft 31, and the upper connecting rod 32 is connected through the third pin shaft 33 is connected with the lower link 34, and the lower l...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com