Automatic abrasive paper clamping type flexible automatic grinding device

A clamping and sandpaper technology, which is applied in the direction of grinding machines, grinding machine parts, grinding/polishing equipment, etc., can solve the problems of easy damage of sandpaper clips and difficulties in loading and unloading sandpaper, so as to improve production efficiency, reduce vibration, reduce The effect of human cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0035] The present invention will be more clearly and completely described below by way of a preferred embodiment with reference to the accompanying drawings, but the present invention is not limited to the scope of the described embodiment.

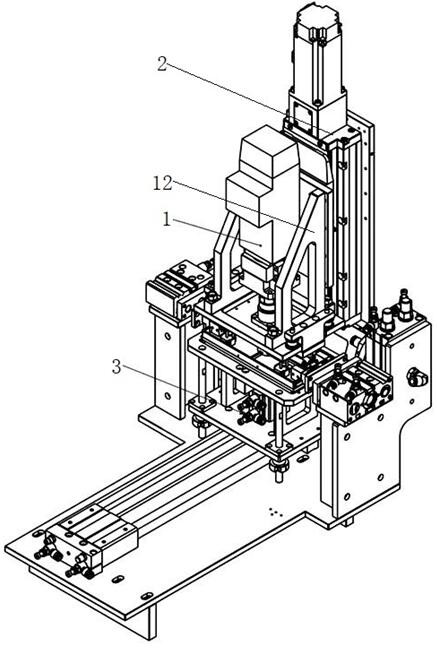

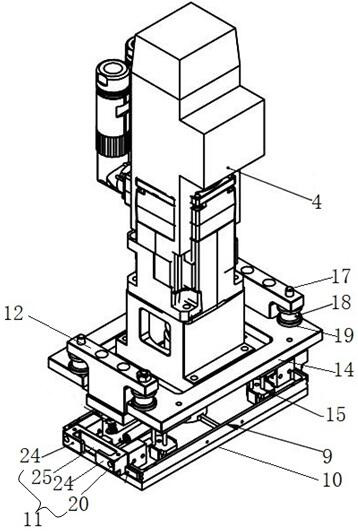

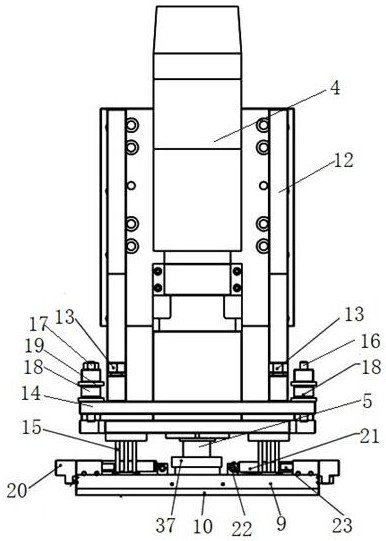

[0036] Such as Figure 1-Figure 5Shown is a kind of automatic sandpaper clamping type flexible automatic grinding device provided by the present invention, including a grinding device 1, a moving mechanism 2 for driving the grinding device to move in space, and a sandpaper loading and unloading device for replacing sandpaper on the grinding device Device 3, the grinding device and the moving mechanism are fixed by installing a fixed frame 12. The moving mechanism 2 includes a horizontal moving component and a vertical moving component, both of which adopt a transmission structure of a motor, a slide rail, and a slider, and the vertical moving component is fixed on a horizontal The transmission end of the moving assembly is fixed on the t...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com