Provisioning vehicle-mounted intelligent inspection robot system and method

A robot system and intelligent inspection technology, applied in the directions of manipulators, vehicle components, cable installation devices, etc., can solve the problems of low inspection efficiency, reduced image segmentation accuracy, and area inspection personnel missing poles, etc., to improve inspection efficiency. and inspection quality, improve real-time and accuracy, and achieve the effect of effective segmentation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

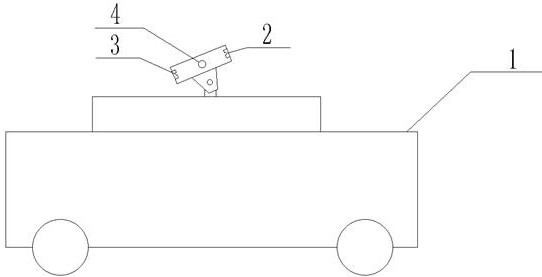

[0066] Such as figure 1 As shown, Embodiment 1 of the present invention provides a vehicle-mounted intelligent inspection robot system for a distribution network, including: a robot body installed on the vehicle 1 and a detection device mounted on the robot body;

[0067] The detection device at least includes an ultrasonic detection mechanism 2, an infrared detection mechanism 4, and a visible light imaging mechanism 3 fixed on the rotating platform, and the ultrasonic detection mechanism and the visible light imaging mechanism are arranged coaxially and oppositely, or the ultrasonic detection mechanism and the visible light imaging mechanism are arranged in opposite directions. The included angle is the default value.

[0068] It can be understood that in some other embodiments, the detection device may also include other sensors, such as temperature and humidity sensors, air pressure sensors, etc., which can be selected by those skilled in the art according to specific work...

Embodiment 2

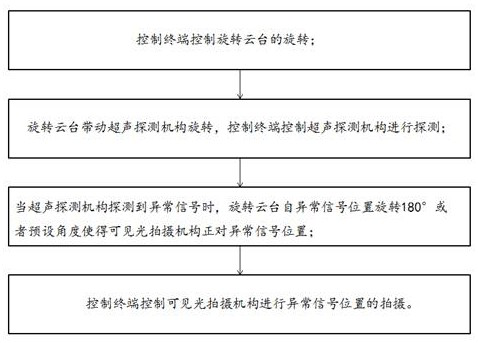

[0073] Embodiment 2 of the present invention provides a method for locating discharge points of power distribution equipment, such as figure 2 As shown, using the distribution network vehicle intelligent inspection robot system described in Embodiment 1 of the present invention includes the following processes:

[0074] S201: the motor of the rotating pan / tilt receives a control command from the control terminal;

[0075] S202: The rotating pan / tilt drives the ultrasonic detection mechanism to rotate, and the ultrasonic detection mechanism performs detection according to the received control command from the control terminal;

[0076] S203: When the ultrasonic detection mechanism detects an abnormal signal, the rotating platform rotates 180° from the position of the abnormal signal so that the visible light imaging mechanism faces the position of the abnormal signal;

[0077] S204: The visible light photographing mechanism photographs the position of the abnormal signal acco...

Embodiment 3

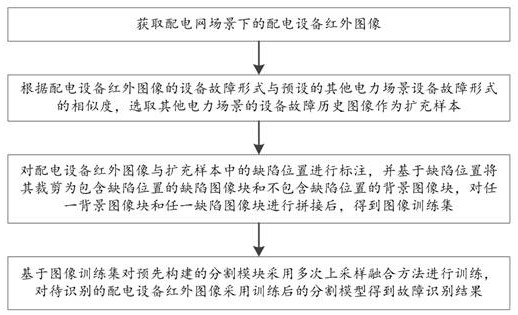

[0080] Embodiment 3 of the present invention provides a fault identification method for power distribution equipment, such as image 3 As shown, using the distribution network vehicle intelligent inspection robot system described in Embodiment 1 of the present invention includes the following processes:

[0081] S301: Obtain the historical infrared images of power distribution equipment in the distribution network scene and other preset power scenes, and select the equipment in other power scenes according to the similarity between the equipment failure form of the power distribution equipment infrared image and the equipment failure form in other power scenes Fault history images are used as extended samples;

[0082] Preferably, the structural similarity algorithm is used to select samples with similar defect forms for expansion; for example, there are many bird nests in the power transmission scene, but there are very few bird nests in the power distribution scene, so a new...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com