Automatic tray discharging mechanism for carrier tape production

An automatic unloading and palletizing technology, which is used in thin material handling, strip winding, transportation and packaging, etc., can solve the problems of easy damage and deformation of the reel, heavy reel weight, etc., to improve the feeding efficiency, unloading The effect of convenient material and prevention of damage and deformation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0040] The following is attached Figure 1-8 The application is described in further detail.

[0041] The embodiment of the present application discloses an automatic unloading mechanism for trays used for tape production.

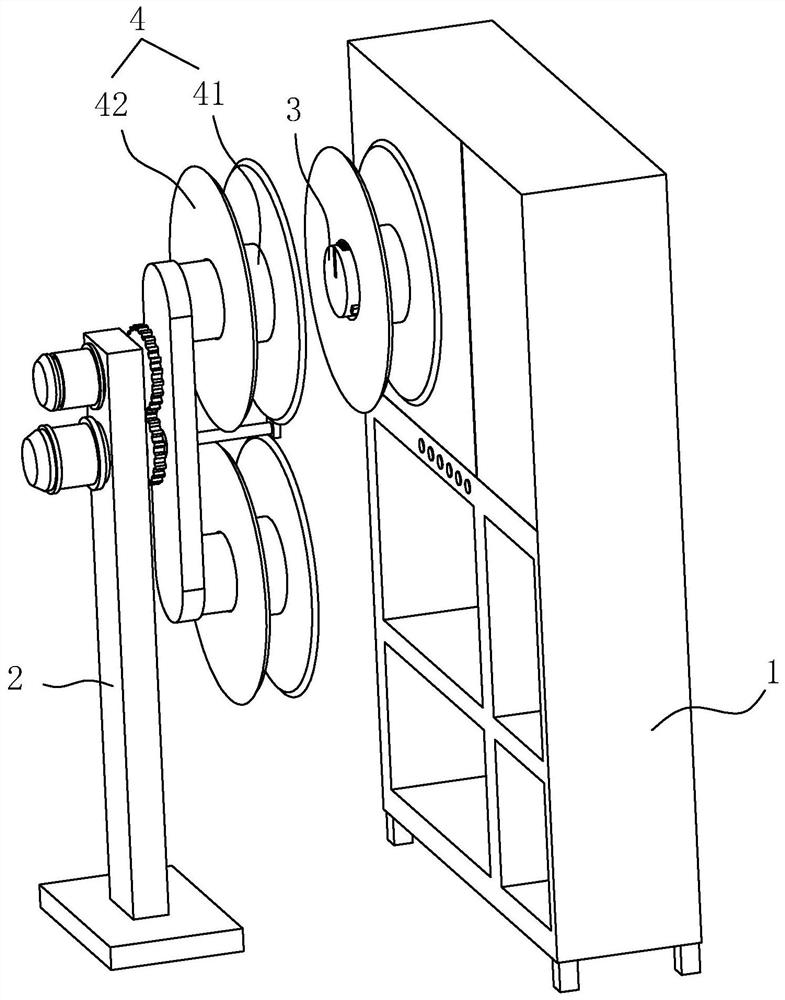

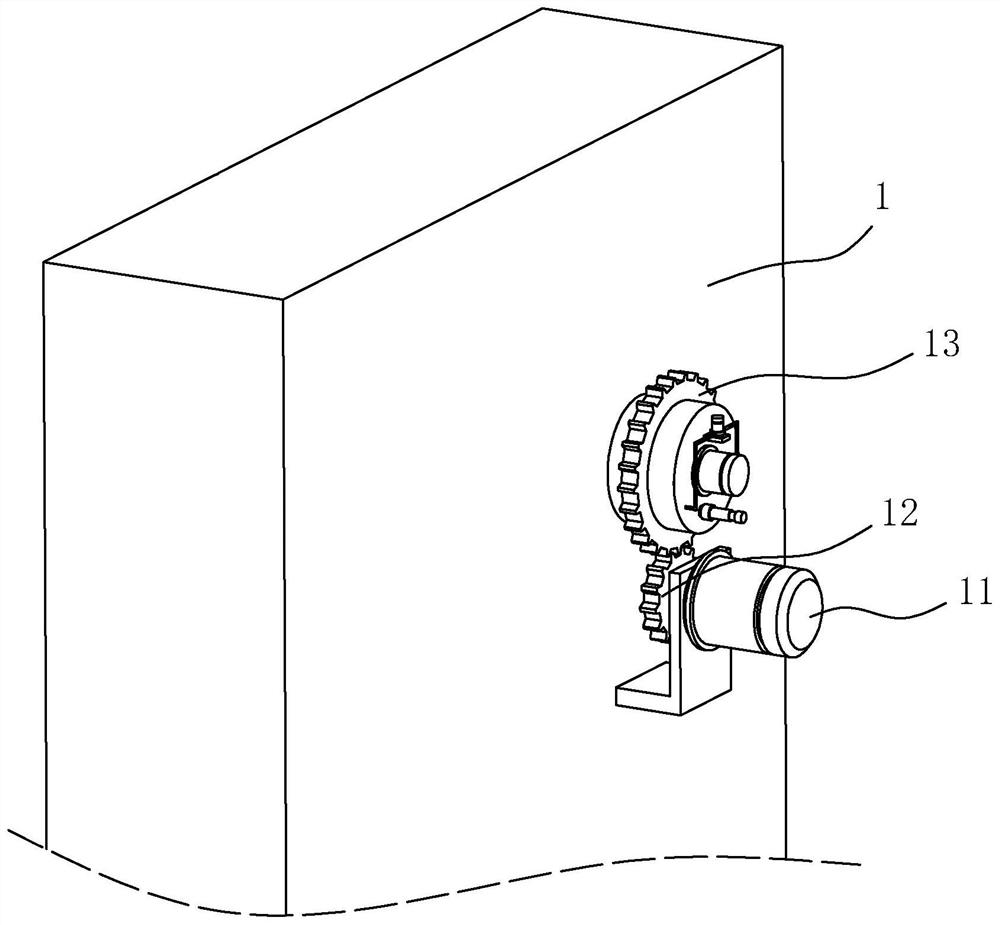

[0042] refer to figure 1 , figure 2 , an automatic pallet unloading mechanism for carrier tape production, comprising a body 1 and an unloading frame 2, a roll 3 is rotated on the body 1, a reel 4 is set on the roll 3, and the reel 4 includes a reel 41 And baffle plate 42. A motor 11 is fixedly arranged on the body 1, a first gear 12 is fixedly arranged on the output shaft of the motor 11, and a second gear 13 is fixedly arranged coaxially on one end of the winding roller 3 passing through the body 1, and the first gear 12 and the second gear 13 meshes.

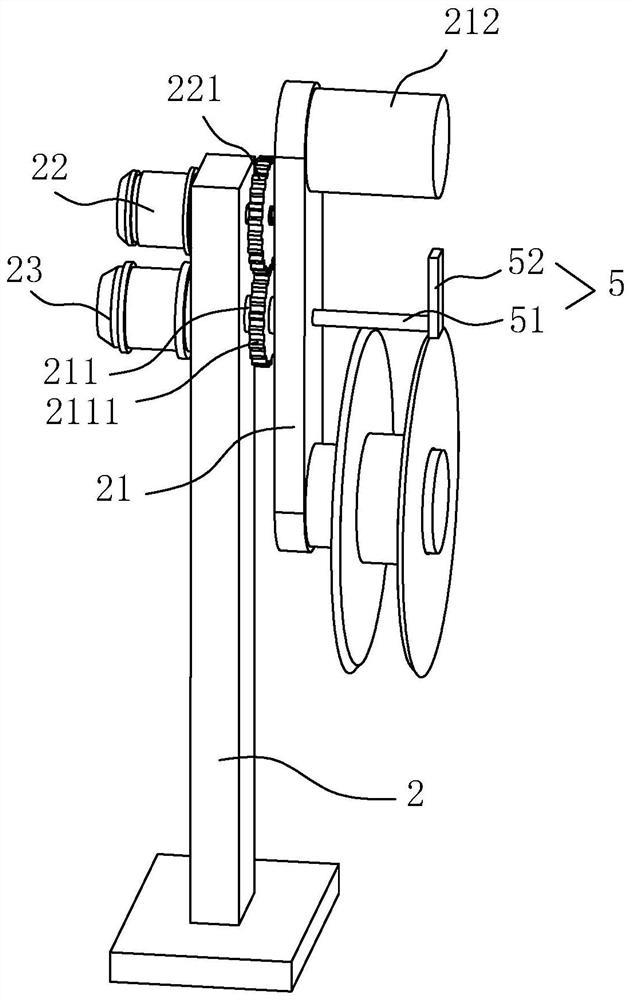

[0043] refer to figure 1 , image 3 , the unloading frame 2 is provided with a rotating arm 21, the unloading frame 2 is provided with a rotating cylinder 211, and the rotating arm 21 is fixedly a...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com