Method for biosynthesizing phenolic acid compounds by using lignin and application of phenolic acid compounds

A technology for biosynthesis and phenolic acids, applied in microorganism-based methods, biochemical equipment and methods, microorganisms, etc., can solve the problems of a large number of waste liquids, waste residues, environmental pollution, pollution, and high waste water treatment costs, and achieve less raw materials. , high efficiency and low cost

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

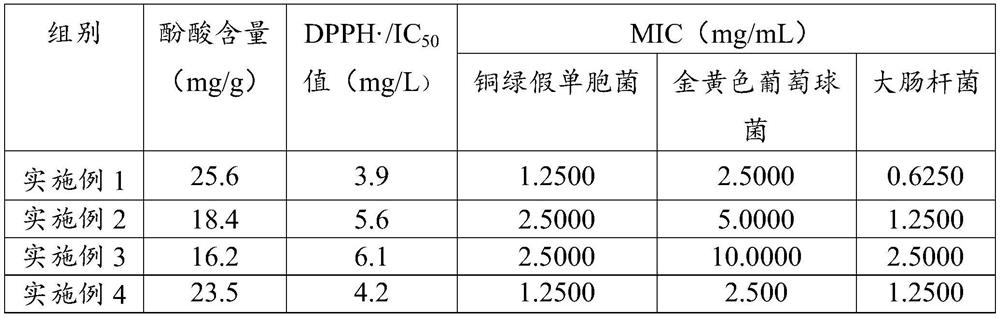

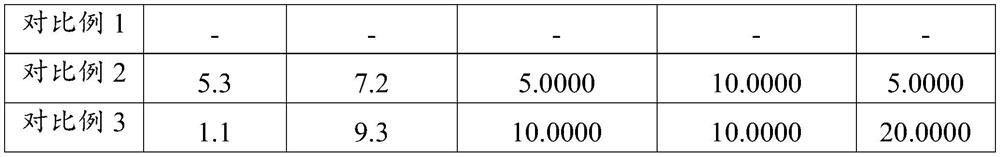

Examples

Embodiment 1

[0035] A method for utilizing lignin to biosynthesize phenolic compounds, comprising the following steps:

[0036] 1) Pick Bacillus siamensis (Bacillus siamensis) L5 single colony into LB liquid medium for pre-cultivation for 12h to obtain a premix, centrifuge the premix at 4000r / min for 2min, then discard the supernatant and leave the bacteria The body was washed with Tris-HCl solution and resuspended to obtain Bacillus siamese L5 bacterial solution, and the concentration of Bacillus siamese L5 in the bacterial solution was 10 5 ~10 6 CFU / mL, more preferably, the concentration of Bacillus siamese L5 in the bacterial liquid is 10 6 CFU / mL;

[0037] 2) Inoculate 500uL of Bacillus siamese bacterial liquid and 250uL of laccase into a 250mL conical flask of 50mL Tris-HCl solution, and add alkali lignin to obtain a mixed solution, so that the final concentration of alkali lignin in the mixed solution is 1000mg / L, the mixture was shaken and cultured for 1 day at a temperature of...

Embodiment 2

[0040]A method for utilizing lignin to biosynthesize phenolic compounds, comprising the following steps:

[0041] 1) Pick Bacillus siamensis (Bacillus siamensis) L5 single colony into LB liquid medium for pre-cultivation for 12h to obtain a premix, centrifuge the premix at 4000r / min for 2min, then discard the supernatant and leave the bacteria The body was washed with Tris-HCl solution and resuspended to obtain Bacillus siamese L5 bacterial solution, and the concentration of Bacillus siamese L5 in the bacterial solution was 10 5 ~10 6 CFU / mL;

[0042] 2) Inoculate 500uL of Bacillus siamese bacterial liquid and 500uL of laccase into a 250mL conical flask of 50mL Tris-HCl solution, and add alkali lignin to obtain a mixed solution, so that the final concentration of alkali lignin in the mixed solution is 1000mg / L, the mixture was shaken and cultured for 1 day at a temperature of 30 °C and a rate of 150 r / min, centrifuged to take the supernatant, added 50 mL of ethyl acetate an...

Embodiment 3

[0045] A method for utilizing lignin to biosynthesize phenolic compounds, comprising the following steps:

[0046] 1) Pick Bacillus siamensis (Bacillus siamensis) L5 single colony into LB liquid medium for pre-cultivation for 12h to obtain a premix, centrifuge the premix at 4000r / min for 2min, then discard the supernatant and leave the bacteria The body was washed with Tris-HCl solution and resuspended to obtain Bacillus siamese L5 bacterial solution, and the concentration of Bacillus siamese L5 in the bacterial solution was 10 5 ~10 6 CFU / mL;

[0047] 2) Inoculate 500uL of Bacillus siamese bacterial liquid and 1mL of laccase into a 250mL conical flask of 50mL of Tris-HCl solution, and add alkali lignin to obtain a mixed solution, so that the final concentration of alkali lignin in the mixed solution is 1000mg / L, the mixture was shaken and cultured for 1 day at a temperature of 30 °C and a rate of 150 r / min, centrifuged to take the supernatant, added 50 mL of ethyl acetate ...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap