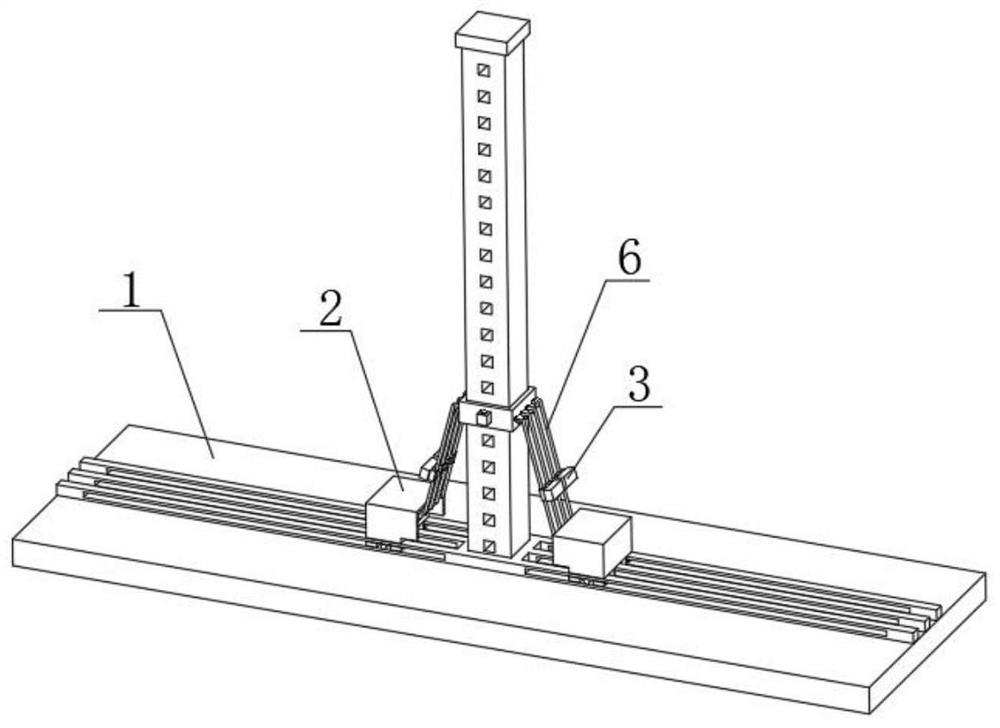

Box girder hogging moment prestress tension protection device

A protection device and negative bending moment technology, applied in bridges, bridge materials, bridge construction, etc., can solve problems such as hidden safety hazards, losses, personnel accidents, etc., and achieve increased load-bearing capacity, increased stability, and increased contact area. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

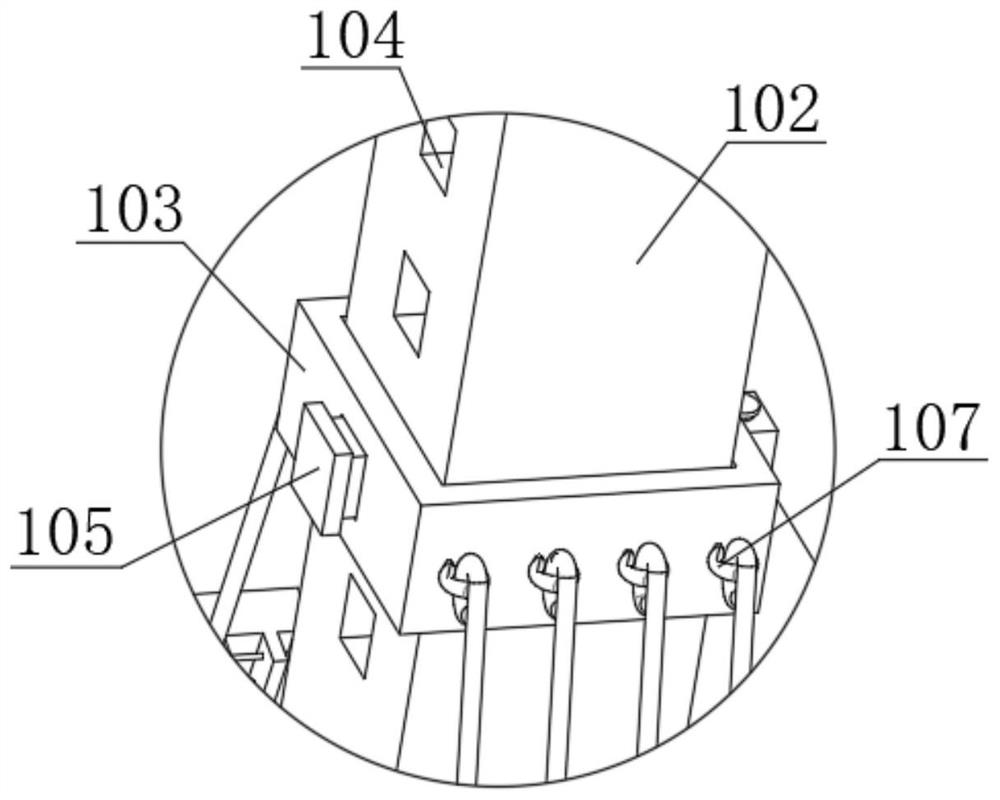

[0049] Embodiment 1: Negative bending moment tension member 1 includes a buffer base plate 101, a central column 102, a predetermined height adjustment seat 103, a positioning hole 104, a positioning rod 105, a limit ring 106, a steel cable twist ring 107, a tension guide rail 108 and The center column 102 is fixedly connected to the middle position of the upper surface of the balance groove 109 and the buffer base plate 101 , and a predetermined height adjustment seat 103 is provided slidingly on the side of the center column 102 .

[0050] The side of the central column 102 is provided with a positioning hole 104, and a positioning rod 105 is provided through the positioning hole 104. The side of the positioning rod 105 is fixedly connected to the limit ring 106, and the side of the center column 102 top is fixedly connected to the limit ring 106, and the predetermined height is adjusted. The side of the seat 103 is fixedly connected with a steel cable hinge 107, and the side...

Embodiment 2

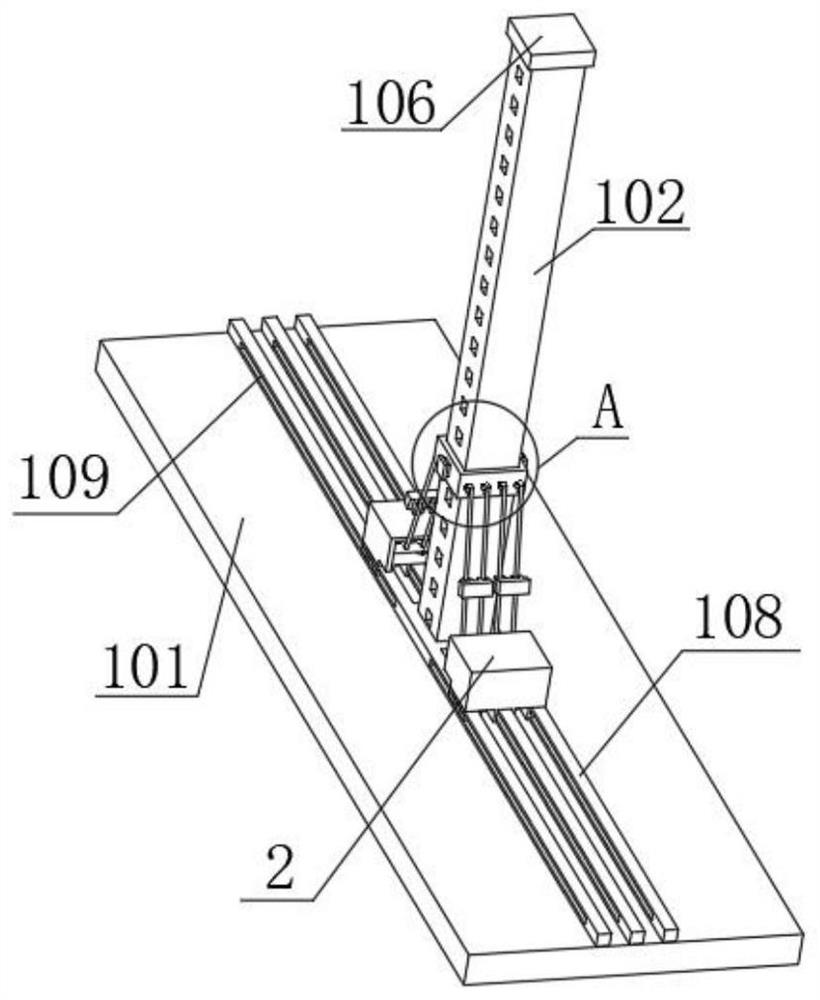

[0053] Embodiment 2: The prestress adjusting part 2 comprises a stretching cart 201, a balance plate 202, a pressing plate 203, a sliding block 204, a pressing wheel 205 and a limit strip 206, and the stretching cart 201 is arranged above the buffer base plate 101, and is connected with The tension guide rail 108 cooperates with the layout of the tension steel cable 6 .

[0054] The side of the tensioning trolley 201 is fixedly connected with a balance plate 202, and the side of the tensioning trolley 201 close to the central column 102 is fixedly connected with a pressing plate 203, and the side of the tensioning trolley 201 is fixedly connected with a sliding block 204 adapted to the balance groove 109 , the balance plate 202 is fixedly connected to the side of the sliding block 204, and the balance plate 202 extends into the inner side of the balance groove 109, the upper surface of the balance plate 202 is fixedly connected with the pressing wheel 205, and the inner wall of...

Embodiment 3

[0057] Embodiment 3: Segmental tensioning fall-off protection piece 3 includes connecting plate 301, roller 302, connecting cable 303 and counterweight plate 304, the lower surface of connecting plate 301 is fixedly connected with roller 302, and the bottom of roller 302 is provided with connecting cable 303 The end of the connecting cable 303 away from the roller 302 is fixedly connected with a weight plate 304 .

[0058]The connecting plate 301 is vertically arranged with the tension steel cable 6, the lower surface of the connecting plate 301 is fixedly connected with a fixed plate 7, and the two fixed plates 7 are fixedly connected with a rotating shaft 8, and the bearing of the roller 302 is connected to the side of the rotating shaft 8, and the roller 302 A limit rolling groove 9 compatible with the tensioning steel cable 6 is opened on the side of the side, and the roller 302 is clamped with the tensioning steel cable 6 through the limit rolling groove 9 .

[0059] The ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com