Stepped gate, gate structure and stepped gate parameter determination method and system

A grid structure and parameter determination technology, applied in the direction of using plasma, thrust reverser, machine/engine, etc., can solve the problems of poor plasma uniformity, small size of miniature ion thrusters, and reduced ion beam extraction efficiency, etc., to achieve good focus effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

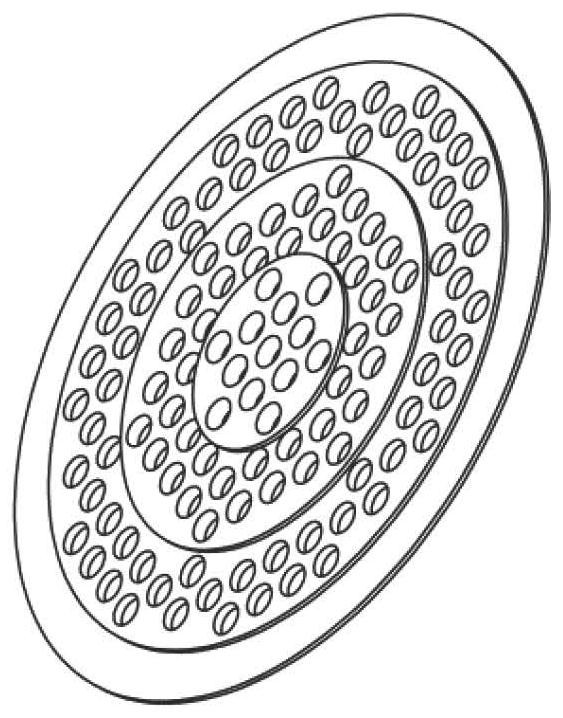

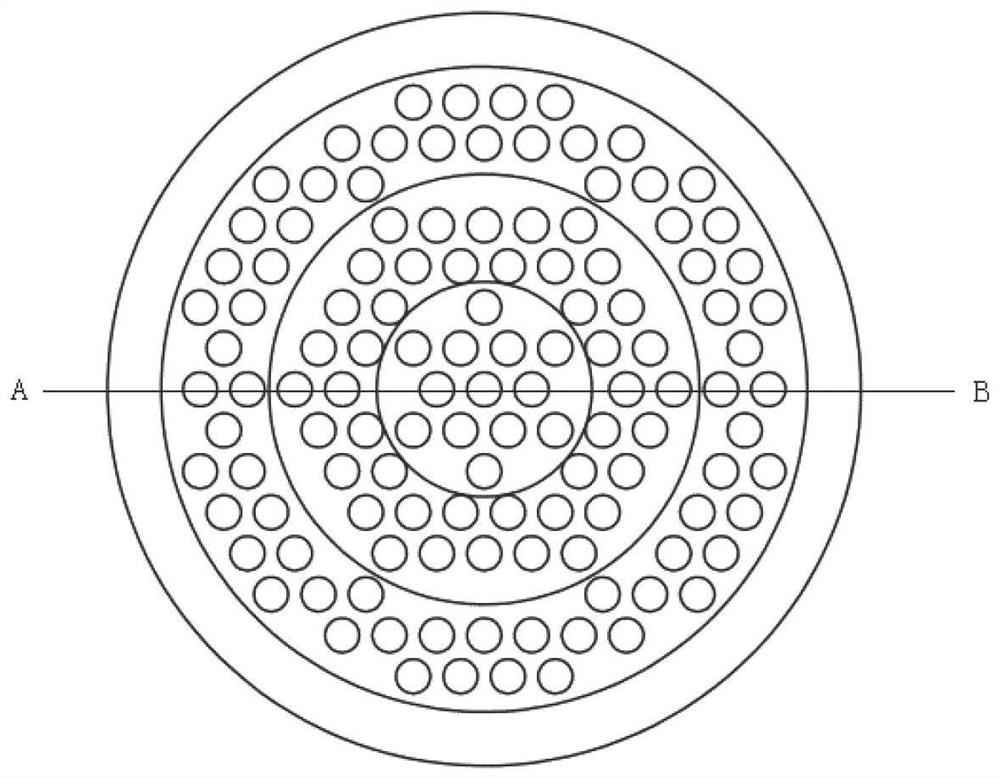

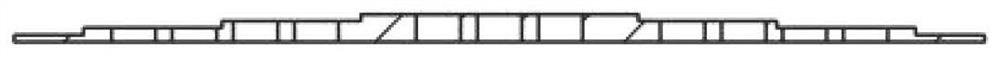

[0052] The invention provides a stepped grid suitable for ion thrusters, such as Figure 1-3 As shown, one side of the ladder gate is stepped, and the other side is flat;

[0053] The stepped grid is divided into a central area, a transition area and an edge area along the radial direction; multiple grid holes are set in the central area, transition area and edge area;

[0054] The thicknesses of the central region, the transition region and the edge region decrease sequentially, and the distances from the central region, the transition region and the edge region to another gate increase sequentially;

[0055] The ion current density in the central area is greater than the upper limit of the ion current density, the ion current density in the edge area is lower than the lower limit of the ion current density, and the ion current density in the transition area is between the ion current density in the central area and the edge area.

[0056] The central region has the largest ...

Embodiment 2

[0060] A grid structure of an ion thruster, such as Figure 5-7 As shown, the gate structure adopts the step gate provided by Embodiment 1 of the present invention, and the gate structure includes: a screen gate and an acceleration gate, at least one of the screen gate and the acceleration gate is a step gate.

[0061] Such as Figure 5 As shown, when the screen grid is a stepped grid and the accelerating grid is a planar grid, the ladder-shaped side of the screen grid faces the accelerating grid; the structure of the planar grid is as follows Figure 4 shown.

[0062] Such as Figure 6 As shown, when the screen grid is a planar grid and the acceleration grid is a stepped grid, the stepped side of the acceleration grid faces the screen grid; Loss of small beams of ions on the screen grid.

[0063] Such as Figure 7 As shown, when both the screen grid and the acceleration grid are stepped grids, the stepped side of the screen grid is opposite to the stepped side of the acc...

Embodiment 3

[0068] The present invention corresponds to the stepped grid of Embodiment 1 and the grid structure of Embodiment 2, and provides a method for determining the parameters of the stepped grid suitable for ion thrusters, such as Figure 8 As shown, the parameter determination methods include:

[0069] Step 101, determine the grid parameters at the center of the ion thruster through the thruster beam extraction experiment, as the grid parameters of the central area of the stepped grid; grid parameters include grid spacing, grid thickness and grid hole diameter; grid The pole pitch is the distance between the central area of the stepped gate and the two opposite faces of another gate in the gate structure; the gate thickness is the thickness of the central area of the stepped gate;

[0070] Step 102, according to the grid parameters of the central area, determine the effective acceleration distance of the central area, specifically including:

[0071] According to the gate p...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com