An air separation device and method capable of exchanging the internal and external compression processes of oxygen

A technology of air separation and oxygen, applied in the field of air separation, to achieve the effect of reducing occupied space, simple operation, convenient placement and installation

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

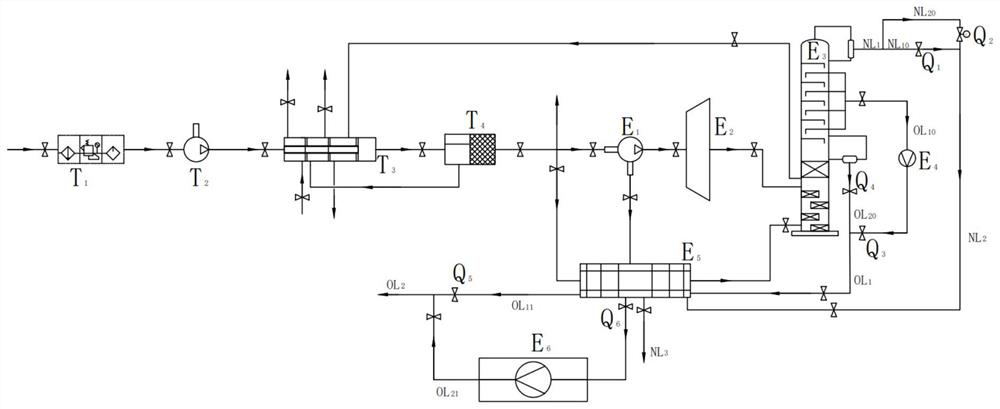

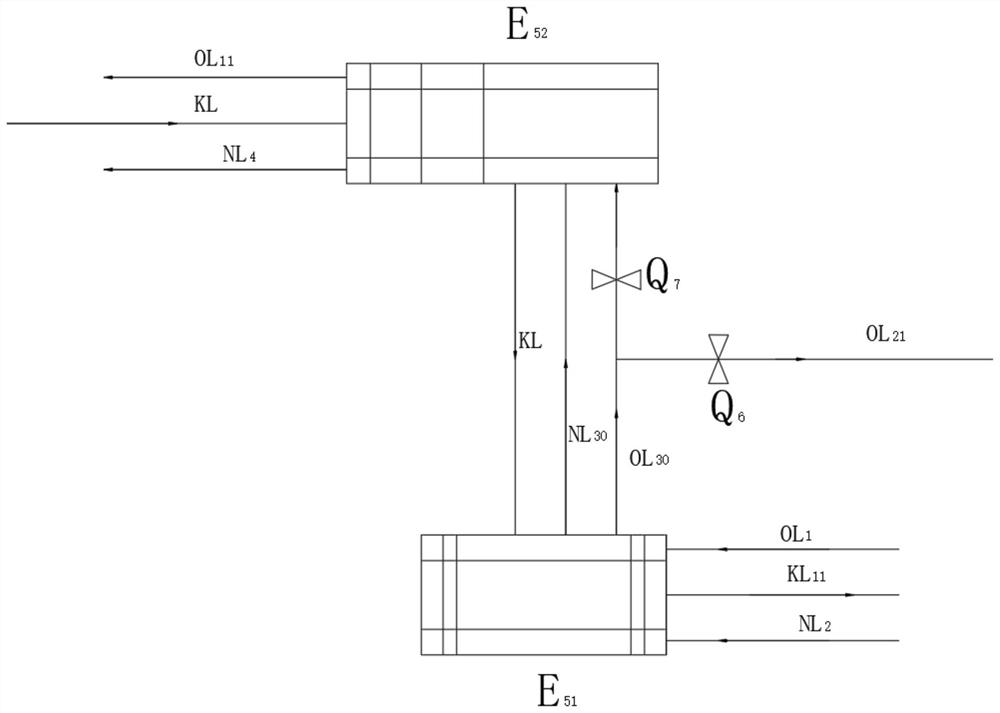

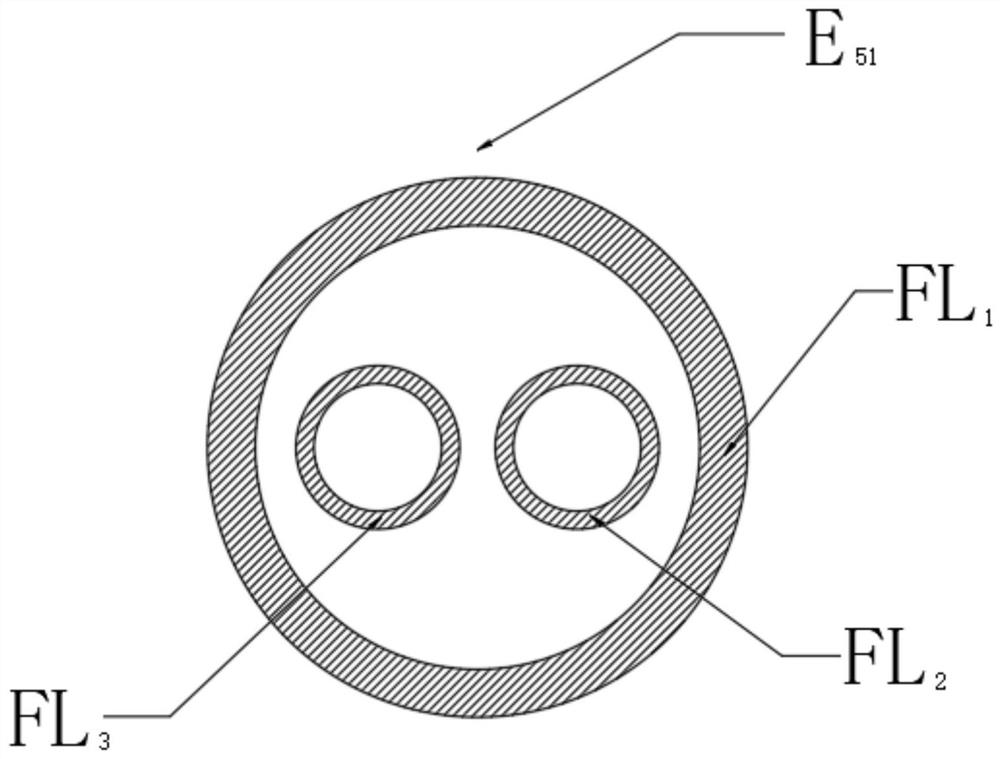

[0035] see Figure 1-6The present invention provides a technical solution: an air separation device and method capable of exchanging the internal and external compression processes of oxygen, including a self-cleaning filter T1, a centrifugal compressor T2, a pre-cooling system T3, a molecular purifier T4, Air booster E1, turbo expander E2, rectification tower E3, liquid oxygen pump E4, main heat exchanger E5 and oxygen compressor E6, self-cleaning filter T1 is connected to centrifugal compressor T2 through pipelines, and centrifugal Type compressor T2 is connected to the precooling system T3 through pipelines, and the precooling system T3 is connected to the molecular purifier T4 through pipelines. The molecular purifier T4 is provided with a reverse flow pipeline, and the reverse flow pipeline is connected to the precooling system T3;

[0036] Air booster E1 and main heat exchanger E5 are respectively connected to molecular purifier T4 through pipelines, air booster E1 is re...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com