Novel supporting column porcelain bottle wire fixing and eddy current wire damage preventing device

A pillar porcelain and anti-eddy current technology, which is applied in the direction of cable suspension, overhead installation, cable installation, etc., can solve the problems of increased wire galloping, damage, and drop of distribution wires, so as to ensure stability and easy use , the effect of easy replacement

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

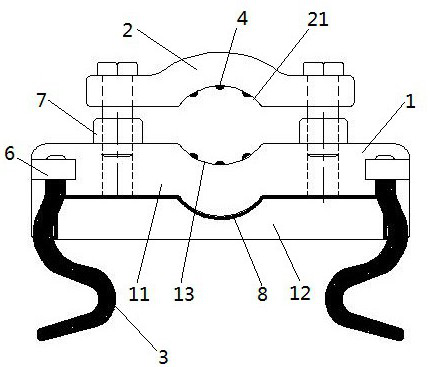

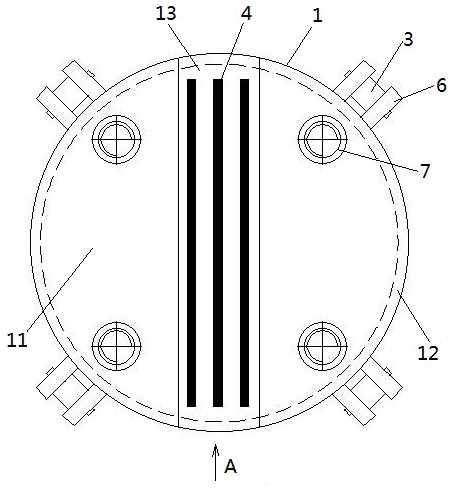

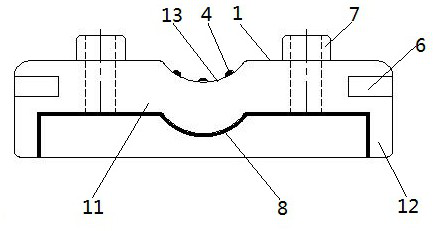

[0020] Refer to attached figure 1 , attached figure 2 , attached image 3 , attached Figure 4 , attached Figure 5 , attached Image 6 , a new type of pillar porcelain bottle solid line anti-eddy current loss line device of the present invention, it is composed of base 1, pressure plate 2, buckle 3, anti-slip rib 4, cable tie 5, connecting seat 6, stud 7, rubber protective layer 8 , there are four connecting seats 6 on the circumference of the base 1; buckles 3 are hinged on the connecting seats 6; studs 7 are arranged symmetrically on both sides of the wire slot I13; Trough II 21, bolt hole 22; the bolt hole 22 is set corresponding to the stud 7; the cable tie 5 is used to bind the buckle 3; the stud 7 is an internal thread stud; the wire slot I13, the wire slot II21 Anti-slip ribs 4 are respectively provided inside; rubber protective layers 8 are respectively provided on the contact surfaces of the bottom plate 11, the hanging plate 12, the buckle 3 and the porcelain ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com