Intelligent self-service rice husking machine

A rice milling machine and intelligent technology, applied in the field of rice milling machines, can solve problems such as unwillingness to buy rice, and achieve the effect of increasing interest in use, improving the effect of shelling, and facilitating the increase of stock.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

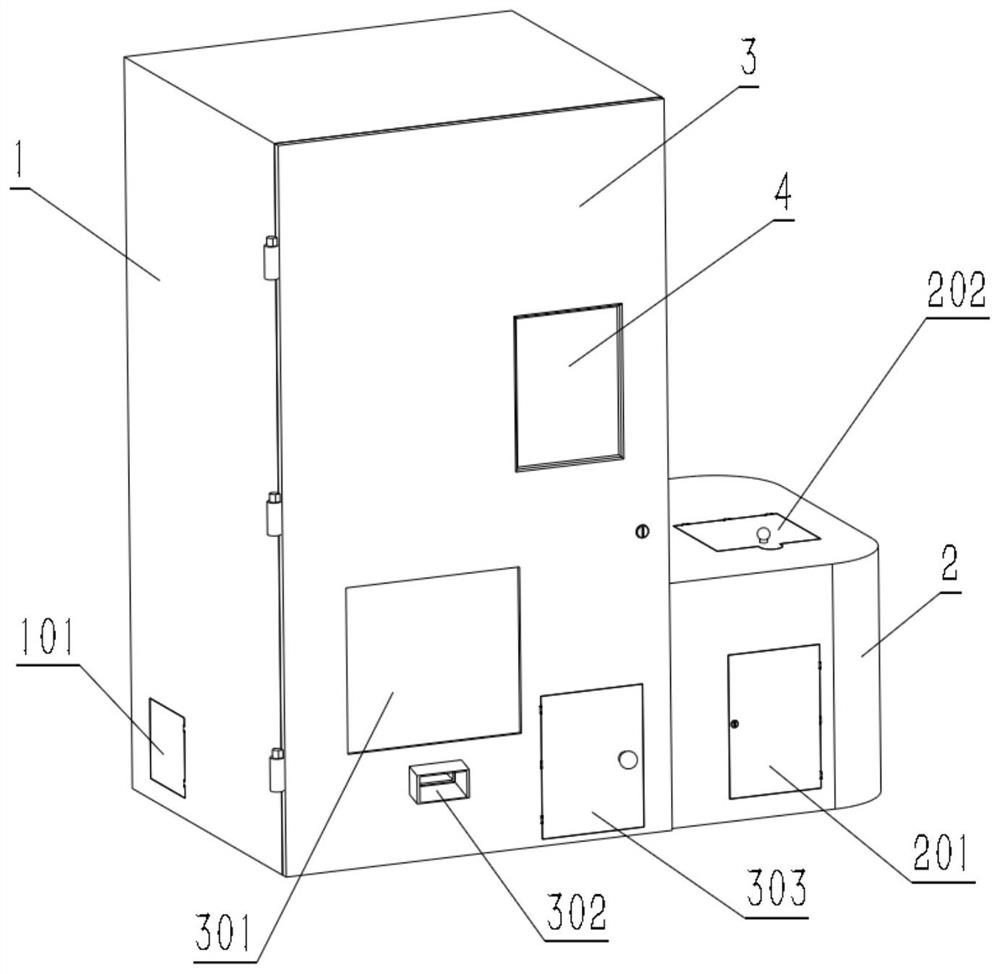

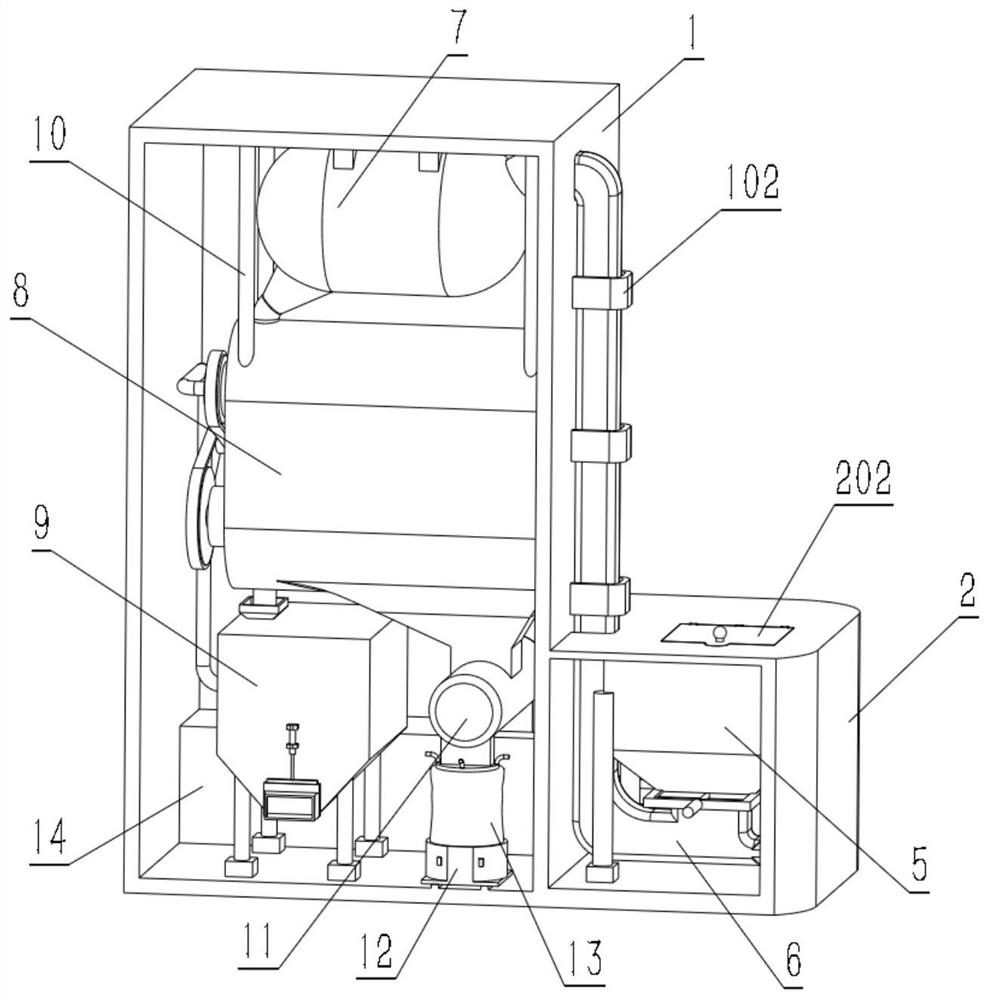

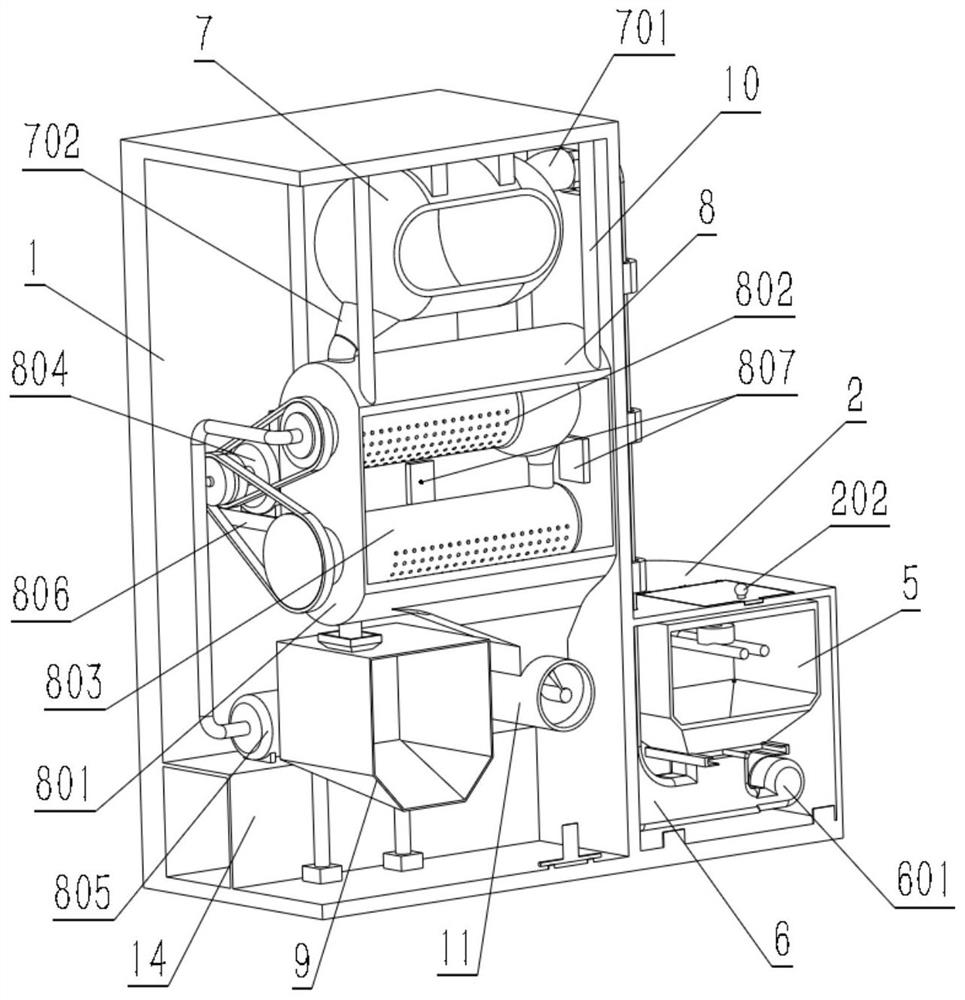

[0026] like Figure 1 to Figure 11 As shown, a kind of intelligent self-service rice milling machine of the present invention adopts the technical scheme that comprises a main frame 1, a main frame door 3 is installed on the front of the main frame 1, and a side frame 2 is fixedly connected to the right side, and the left side of the main frame 1 A chaff bin door 101 is installed at the rear part of the side, the chaff bin door 101 is fixedly connected with a chaff collection bin 14 in the inner cavity of the main engine box 1 corresponding to the chaff bin door 101, and a pushing device 15 is installed at the other end of the chaff bin 14, The pressing device 15 includes a chaff pressing electric telescopic rod 1501 fixedly connected to the side wall of the main chassis 1, and the telescoping end of the chaff pressing electric telescopic rod 1501 stretches into the chaff collection bin 14 and is fixedly connected with a pushing plate 1502, which slides and fits Located in the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com