Rapid activation method of lactococcus lactis and application of lactococcus lactis in yoghourt

A technology of Lactococcus lactis and activation method, applied in the direction of Streptococcus/Lactococcus, microorganism-based methods, biochemical equipment and methods, etc., can solve the problems of low viable bacteria, poor stability and poor activity of liquid starter, etc. Achieve the effects of saving production costs, reducing the risk of bacterial contamination, and increasing the effective number of viable bacteria in the product

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

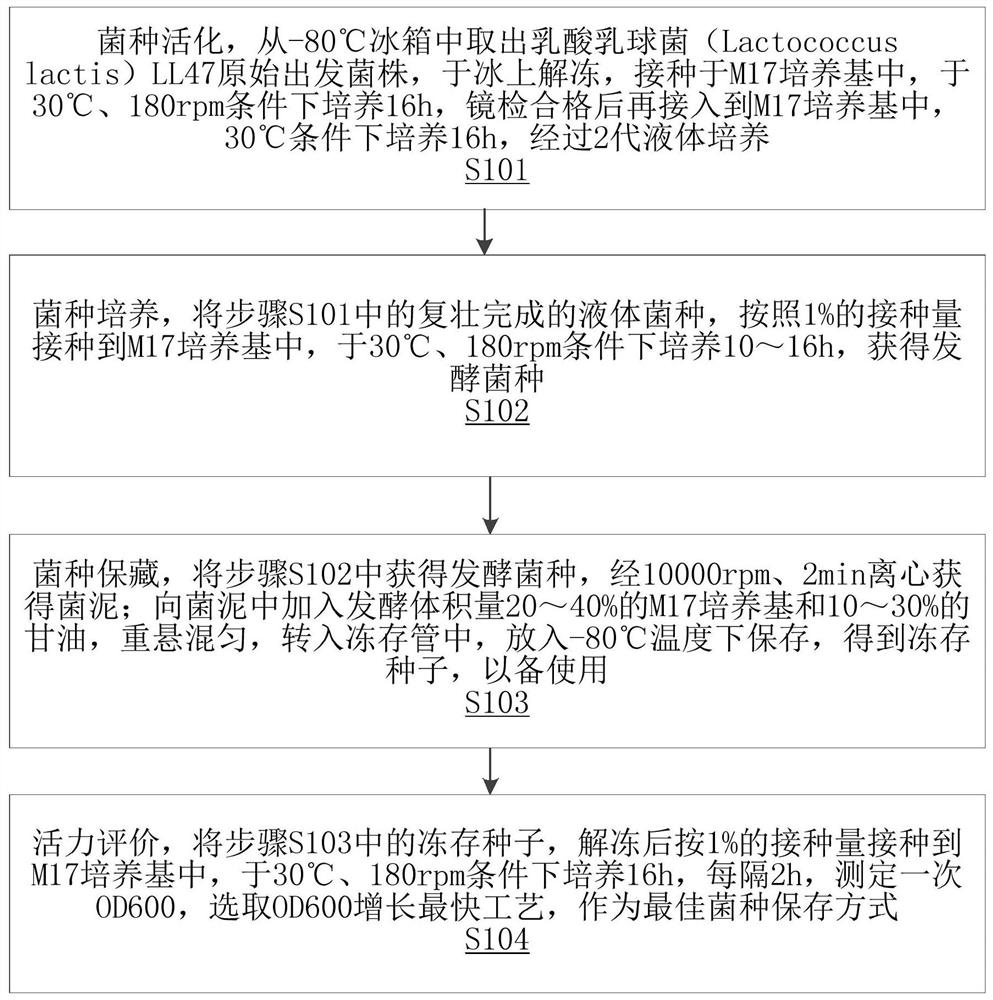

[0024] Example 1, see figure 1 , In this embodiment, the present invention provides the following technical solution: a rapid activation method for Lactococcus lactis, the activation method comprising:

[0025] S101: Strain activation, take out the original starting strain of Lactococcus lactis (Lactococcus lactis) LL47 from the -80°C refrigerator, thaw it on ice, inoculate it in M17 medium, culture it at 30°C and 180rpm for 16 hours, and pass the microscopic examination Then it was inserted into the M17 medium, cultivated at 30°C for 16 hours, and underwent 2 generations of liquid culture to improve the viability of the strain;

[0026] S102: Strain culture, inoculate the liquid strain that has been rejuvenated in step S101 into the M17 medium according to the inoculum amount of 1%, and cultivate it at 30° C. and 180 rpm for 10 hours to obtain the fermented strain;

[0027] S103: strain preservation, the fermented strains obtained in step S102 were centrifuged at 10,000 rpm ...

Embodiment 2

[0029] Example 2, see figure 1 , In this embodiment, the present invention provides the following technical solution: a rapid activation method for Lactococcus lactis, the activation method comprising:

[0030] S101: Strain activation, take out the original starting strain of Lactococcus lactis (Lactococcus lactis) LL47 from the -80°C refrigerator, thaw it on ice, inoculate it in M17 medium, culture it at 30°C and 180rpm for 16 hours, and pass the microscopic examination Then it was inserted into the M17 medium, cultivated at 30°C for 16 hours, and underwent 2 generations of liquid culture to improve the viability of the strain;

[0031] S102: Strain cultivation, inoculate the liquid strain that has been rejuvenated in step S101 into the M17 medium according to the inoculation amount of 1%, and cultivate it at 30° C. and 180 rpm for 12 hours to obtain the fermented strain;

[0032] S103: strain preservation, the fermented strains obtained in step S102 were centrifuged at 10,0...

Embodiment 3

[0034] Example 3, see figure 1 , In this embodiment, the present invention provides the following technical solution: a rapid activation method for Lactococcus lactis, the activation method comprising:

[0035] S101: Strain activation, take out the original starting strain of Lactococcus lactis (Lactococcus lactis) LL47 from the -80°C refrigerator, thaw it on ice, inoculate it in M17 medium, culture it at 30°C and 180rpm for 16 hours, and pass the microscopic examination Then it was inserted into the M17 medium, cultivated at 30°C for 16 hours, and underwent 2 generations of liquid culture to improve the viability of the strain;

[0036] S102: Strain cultivation, inoculate the rejuvenated liquid strain in step S101 into the M17 medium according to the inoculation amount of 1%, and cultivate it at 30° C. and 180 rpm for 14 hours to obtain the fermented strain;

[0037] S103: strain preservation, the fermented strains obtained in step S102 were centrifuged at 10,000 rpm for 2 m...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com