Construction method for high-speed railway double-track tunnel penetrating through vertical mud gushing karst cave

A technology for double-track tunnels and high-speed railways. It is applied in tunnels, tunnel linings, earthwork drilling and mining, etc., and can solve problems such as difficult construction, mud gushing in disturbed and dissolved cavities, and potential safety hazards.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

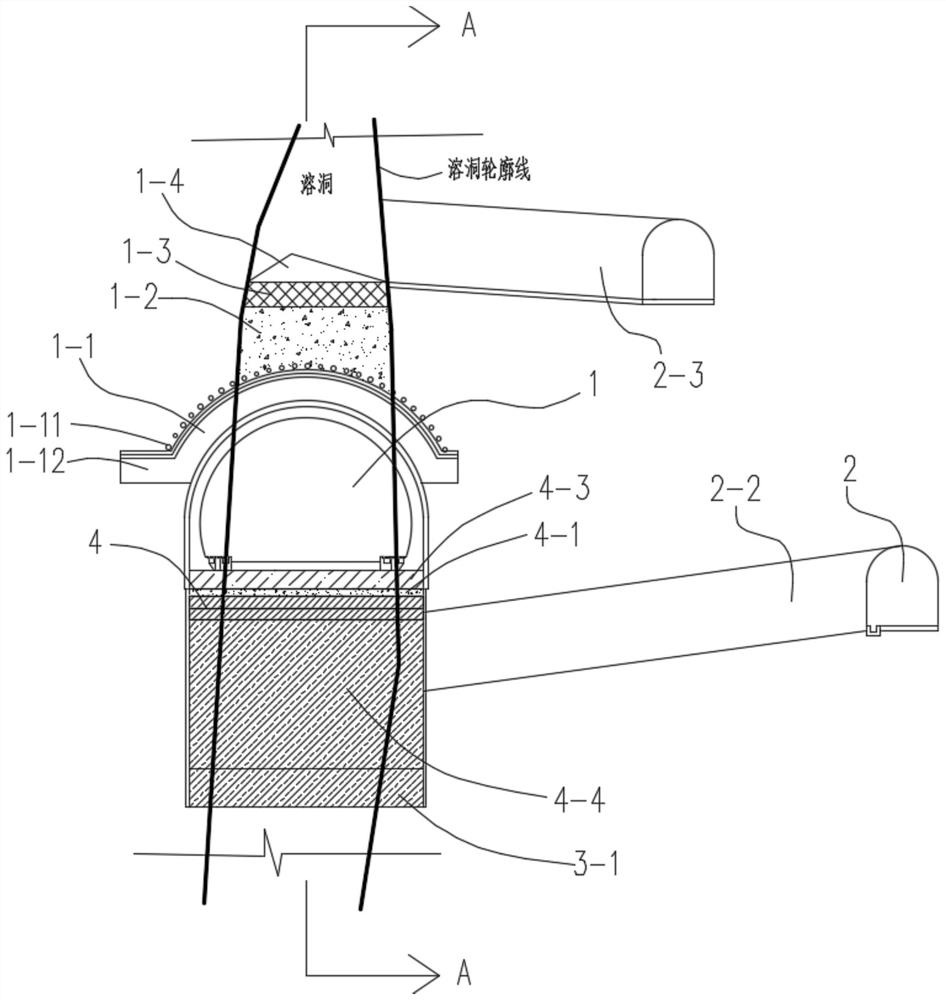

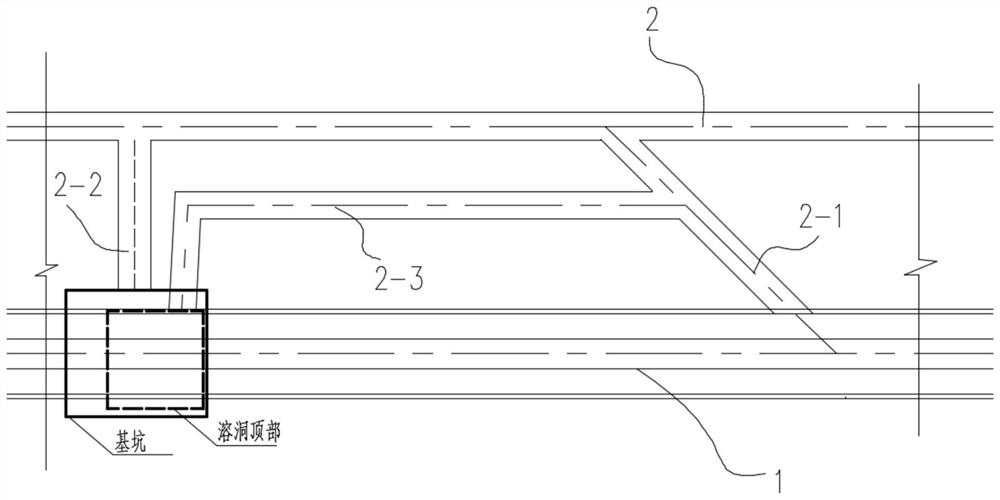

[0041] like figure 1 and figure 2 As shown, a reinforcement system for a high-speed railway double-track tunnel passing through a vertical mud gushing cave, specifically:

[0042] On the top where the main tunnel 1 passes through the karst cave, a protective arch 1-1, a concrete layer 1-2, a flexible buffer layer 1-3 and a protective layer 1-4 are sequentially built from bottom to top;

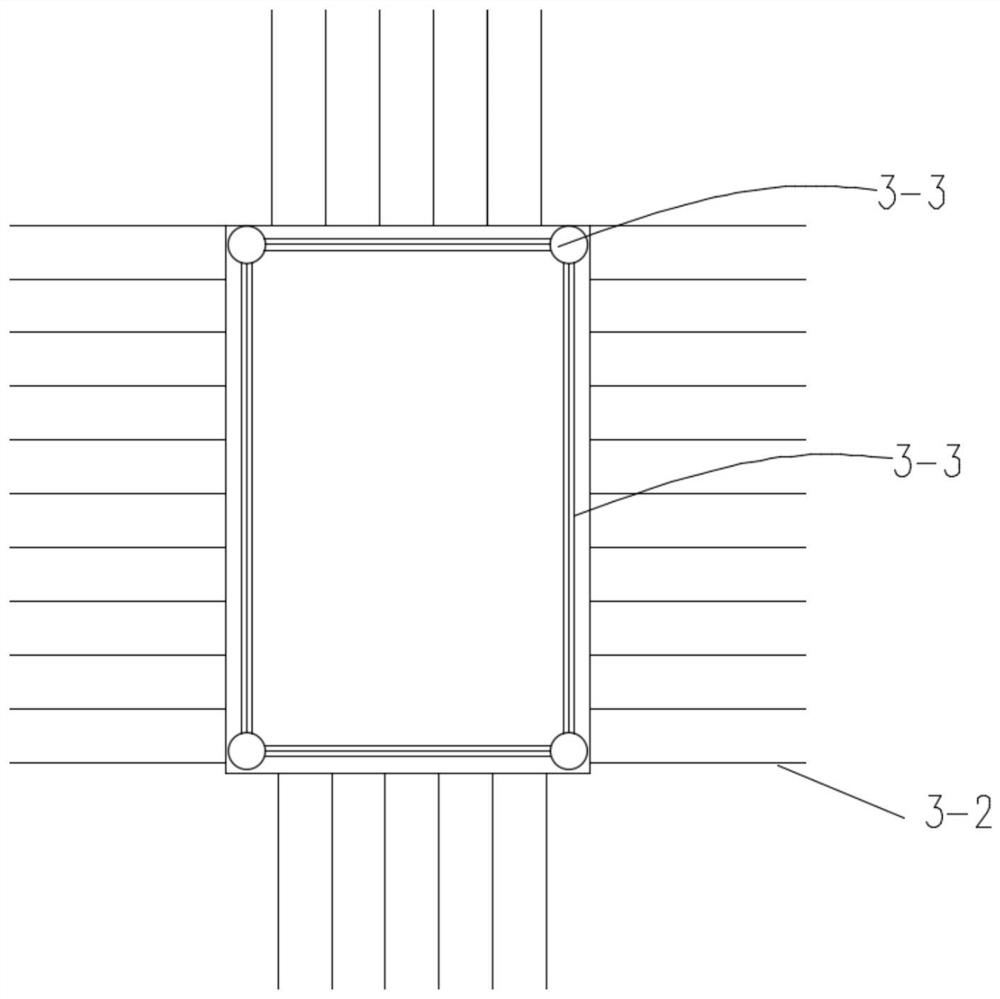

[0043] An arch bridge 4 is built at the bottom where the main tunnel 1 passes through the karst cave. The top of the arch bridge 4 is filled with a filling layer 4-1 of concrete material. Two arched door openings 4-2 are reserved on both sides of the arch bridge 4. A base plate 4-3 of reinforced concrete material is poured above the filling layer 4-1; a foundation cushion 3-1 is provided at the bottom of the foundation pit 3 below the arch bridge 4; a foundation cushion 3-1 is built between the arch bridge 4 and the foundation cushion 3-1 Bearing vertical wall 4-4.

[0044] like Figure 1...

Embodiment 2

[0050] A construction method for a high-speed railway double-track tunnel passing through a vertical mud gushing karst cave, the specific steps are as follows:

[0051] (1) Construct the protective structure on the top of the tunnel

[0052] Build the protective arch 1-1 at the top where the tunnel main hole 1 passes through the karst cave, and then fill the top of the protective arch 1-1 with plain concrete to form a concrete layer 1-2; stack sandbags on the top of the concrete layer 1-2, as Flexible buffer layer 1-3; finally, pouring reinforced concrete on top of the flexible buffer layer 1-3 to form a protective layer 1-4;

[0053] When constructing the arch protection arch 1-1, the pipe-shed method (pipe-shed method) is used for pre-support first, and then the reinforced concrete arch protection arch is constructed; specifically: φ159 steel pipe 1-11 is used for pre-support at a position 10cm outside the outline of the arch protection arch , steel pipes 1-11 with a distan...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com