Novel rubber ball joint

A rubber ball joint, a new type of technology, is applied in the direction of shafts and bearings, pivots, and pivot connections. It can solve the problems of increasing the yaw torsion angle, reducing the yaw torsion stiffness, and increasing the radial stiffness, etc., so as to increase the yaw The effect of torsion angle, reduced torsional stiffness, and increased radial stiffness

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

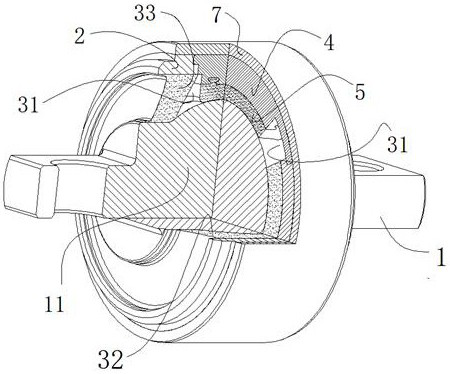

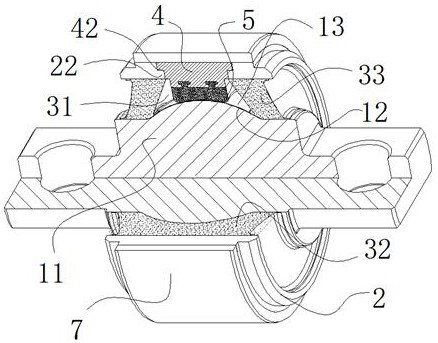

[0036] Such as figure 1 As shown in -7, a new type of rubber ball joint includes a mandrel 1, an outer coat 2 that is coaxial with the mandrel 1 outside the mandrel 1, and is respectively connected to the core by vulcanization between the mandrel 1 and the outer mandrel 2. The rubber layer 3 to which the shaft 1 and the casing 2 are bonded. In the rubber layer 3 on the upper side and the lower side of the mandrel 1, there are symmetrically arranged rubber cavities 31 . In the rubber cavity 31, there is a supporting body whose rigidity is greater than that of the rubber body. The outer side of the supporting body is installed on the jacket, and there is a universal deflection structure between the inner side of the supporting body and the mandrel 1. There are offset gaps between the 31 inner walls. Under working conditions, the supporting body can provide a radial support between the mandrel 1 and the outer casing 2 with a stiffness greater than that of the rubber body. At th...

Embodiment 2

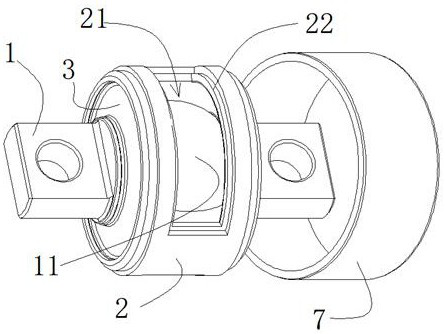

[0046] Such as Figure 8 -shown in 10, its difference with embodiment one is:

[0047] The difference between the spherical radius of the concave spherical surface 51 and the spherical radius of the outer spherical surface 13 is 0.1mm-0.3mm. Since the spherical radius of the outer spherical surface 13 is smaller than that of the concave spherical surface 51 , compared with the first embodiment, the spherical radius of the outer spherical surface 13 remains unchanged, but actually increases the spherical radius of the concave spherical surface 51 . For the processing and assembly of each part of the rubber ball joint of the present invention, the larger the difference between the spherical radius of the concave spherical surface 51 and the spherical radius of the outer spherical surface 13, the processing and assembly can allow a certain centering deviation (concave spherical surface 51 and two sphere centers of the outer spherical surface 13 require to be on a straight line w...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Thickness | aaaaa | aaaaa |

| Thickness | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap