Drying device for plastic granules

A drying device and technology of plastic particles, applied in the field of plastic processing, can solve the problems of thermal fatigue loss of peripheral components, heat dissipation of heaters, affecting drying efficiency, etc., so as to reduce loss efficiency, reduce loss degree, and avoid heat scattered effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

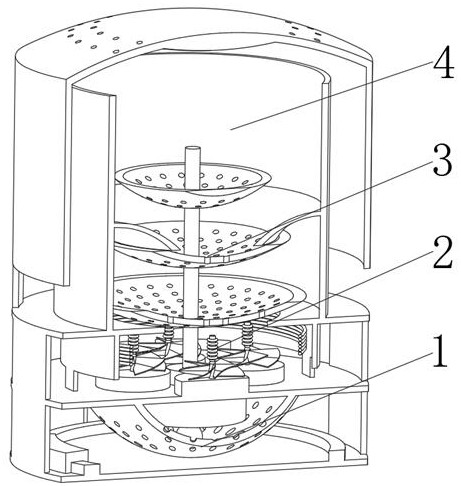

[0042] see Figure 1-5 , the present invention provides a technical solution: a drying device for plastic granules, specifically comprising:

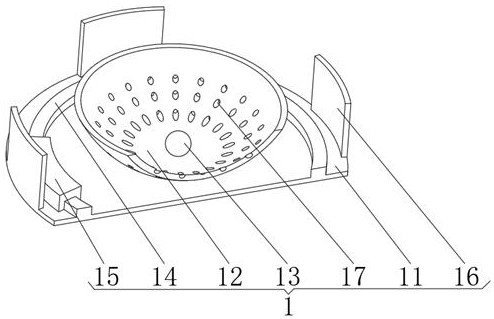

[0043] Reversing seat 1, the reversing seat 1 has a columnar body, and a hot air drying device 2 installed on the top of the reversing seat 1, and a loading tray 3 installed on the top of the hot air drying device 2, and a loading tray arranged on the top of the loading tray 3 The material guiding cylinder 4 on the outer surface, and the hot air drying device 2 include:

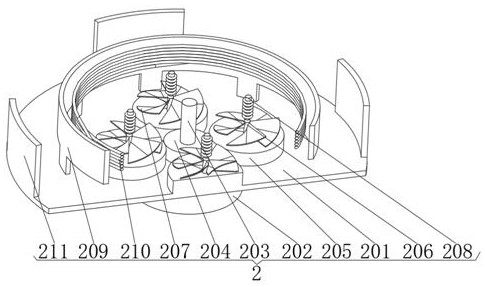

[0044] The temperature insulating plate 201, which has a circular plate body, divides the equipment components through the setting of the temperature insulating plate 201, avoids the relative influence of the temperature between the components, and affects the safety and security of the components themselves. Smoothness is guaranteed. And the drive motor 202 installed in the middle of the bottom of the circular plate body, the transmission shaft 203 installed at the ...

Embodiment 2

[0060] see Figure 1-5 On the basis of Embodiment 1, the present invention provides a technical solution: a method for using a drying device for plastic granules, comprising the following steps,

[0061] Step 1: Pour the plastic particles into the spherical carrier plate 33 in the material carrier plate 3, and accumulate them on the spherical carrier plate 33 with the largest diameter;

[0062] Step 2: The whole device is powered by an external energy source, the current flows through the energy-conducting ring plate 209 and the high-frequency coil 210, and the eddy current is used to make the heat-generating column 208 generate heat;

[0063] Step 3: The current is further transmitted to the driving motor 202, so that the transmission shaft 203 and the transmission sheave 204 are rotated, and the friction force of the transmission sheave 204 is used to drive the driven runner 205 to rotate, so that the fan blade shaft 206 and the fan blade plate 207 are rotated , agitate the...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com