Intelligent radar liquid level meter

A radar level gauge, intelligent technology, applied in the field of measuring instruments, can solve problems such as cumbersome operation, affecting the measurement accuracy of radar level gauge, inconvenient disassembly, etc., to achieve the effect of ensuring measurement accuracy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

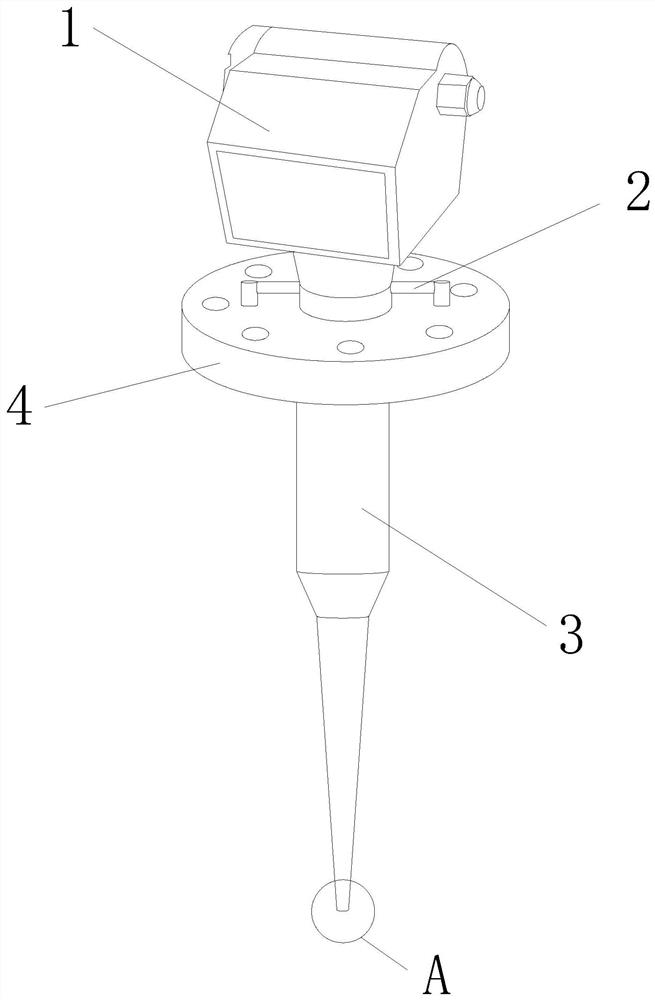

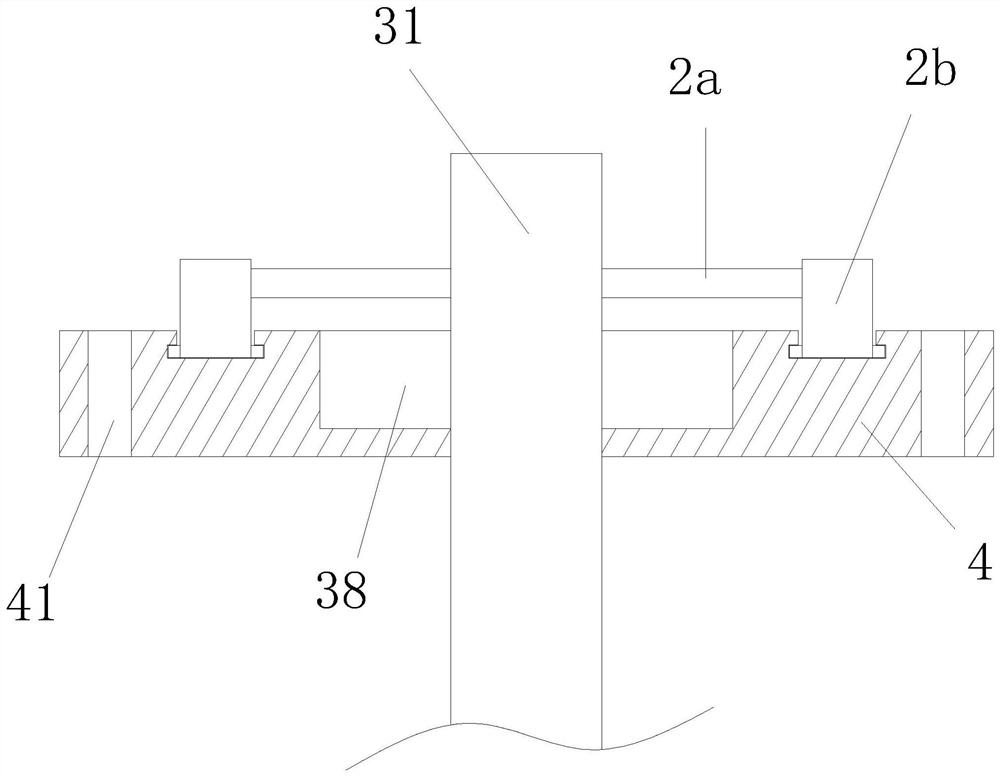

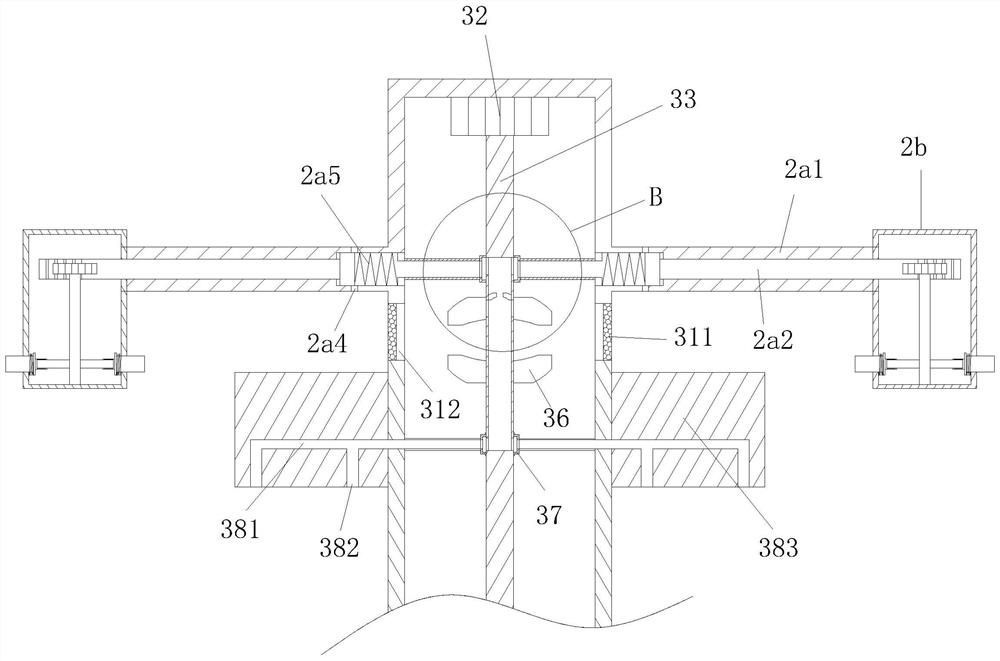

[0028] see Figure 1-4 , the present invention provides an intelligent radar liquid level gauge, the structure of which includes a main body 1, a fixing device 2, a probe 3, and a mounting flange 4, the bottom of the main body 1 is fixed on the top of the probe 3, and the outer surface of the probe 3 is A fixing device 2 is installed on the upper body, the fixing device 2 is located under the main body 1, the fixing device 2 is matched with the mounting flange 4, the mounting flange 4 is located under the fixing device 2 and connected with the probe 3, the probe 3 includes a rod body 31. Micromotor 32, main shaft 33, No. 1 connection ring 34, upflow fan 35, downflow fan 36, No. 2 connection ring 37, adsorption mechanism 38, air jet 39, micromotor 32 and micromotor 32 are installed on the inner top of rod body 31 The output shaft is connected with the top of the main shaft 33, and the outer surface of the main shaft 33 is movably connected with a No. 1 connecting ring 34 and a ...

Embodiment 2

[0037] see Figure 1-4 , the present invention provides an intelligent radar liquid level gauge, the structure of which includes a main body 1, a fixing device 2, a probe 3, and a mounting flange 4, the bottom of the main body 1 is fixed on the top of the probe 3, and the outer surface of the probe 3 is A fixing device 2 is installed on the upper body, the fixing device 2 is located under the main body 1, the fixing device 2 is matched with the mounting flange 4, the mounting flange 4 is located under the fixing device 2 and connected with the probe 3, the probe 3 includes a rod body 31. Micromotor 32, main shaft 33, No. 1 connection ring 34, upflow fan 35, downflow fan 36, No. 2 connection ring 37, adsorption mechanism 38, air jet 39, micromotor 32 and micromotor 32 are installed on the inner top of rod body 31 The output shaft is connected with the top of the main shaft 33, and the outer surface of the main shaft 33 is movably connected with a No. 1 connecting ring 34 and a ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com