Asymmetry calibration method for overlay error measurement

An overlay error and symmetry technology, applied in the field of photolithography, can solve problems affecting measurement accuracy and changes in the intensity distribution of diffracted light

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

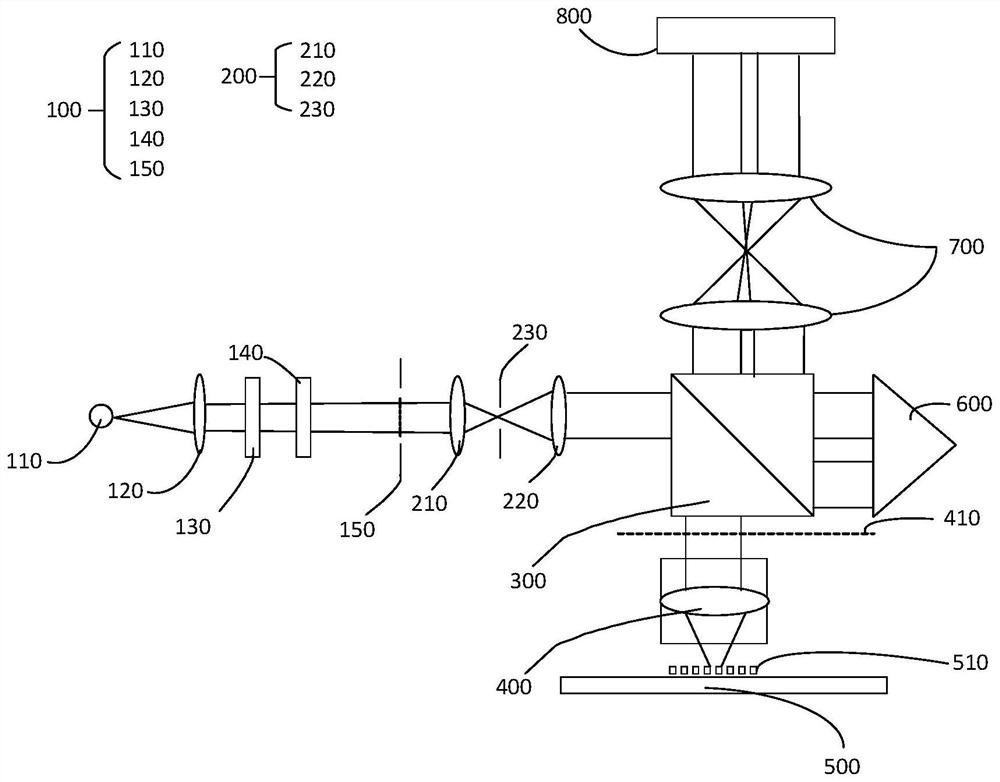

[0051] figure 1 This is a schematic structural diagram of a device for measuring overlay error in this embodiment. like figure 1 As shown, the device for measuring the overlay error includes:

[0052] The light source module 100 is used to provide a measurement spot. The light source module 100 is sequentially provided with: a light source 110 , a collimating lens 120 , a narrow-band filter 130 , a polarizer 140 and an aperture stop 150 along the optical path.

[0053] The light source 110 may be a white light source 110 , a broadband light source 110 or a composite light source 110 composed of several discrete spectral lines. The light source 110 may be a surface light source 110, a line light source 110 or a point light source 110, and a light source 110 with other spot shapes, and the measurement spot generated by the light source module 100 is several of ultraviolet light, visible light, and infrared light. Preferably, the measurement spot is light of a single waveleng...

Embodiment 2

[0115] In the method for asymmetry calibration of overlay error measurement provided in this embodiment, the same parts as those in Embodiment 1 will not be described here, and only different points will be described below.

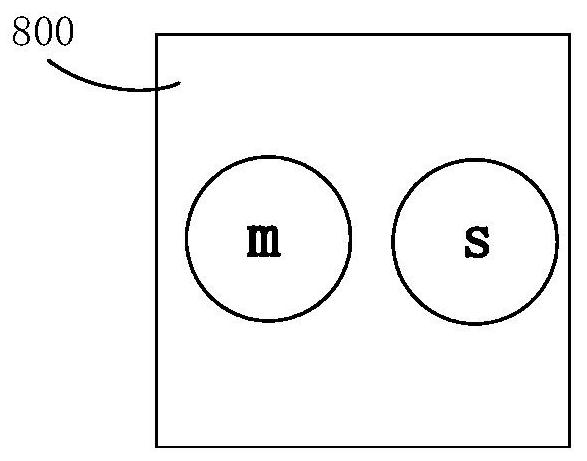

[0116] The difference between this embodiment and the first embodiment is that the step of acquiring the light intensity of the diffracted light by the detector 800 and generating the first reference signal further includes:

[0117] When the detector 800 acquires the diffracted light, the overlay mark 510 moves in multiple steps along the direction of the horizontal component of the measurement spot, and after each step movement, the detector 800 acquires the The light intensity of the diffracted light of the mark 510 is overwritten to generate a first measurement signal, and the average value of the first measurement signals is taken as the first reference signal.

[0118] The step of acquiring the light intensity of the diffracted light by the detector...

Embodiment 3

[0126] In the method for asymmetry calibration of overlay error measurement provided in this embodiment, the same parts as those in Embodiment 1 and Embodiment 2 will not be described here, and only different points will be described below.

[0127] The difference between this embodiment and Embodiment 1 and Embodiment 2 is that, in this embodiment, the device for measuring overlay error may not be provided with the variable field diaphragm 230 or use the variable field diaphragm 230 . The method for asymmetry calibration of overlay error measurement provided by this embodiment includes the following steps:

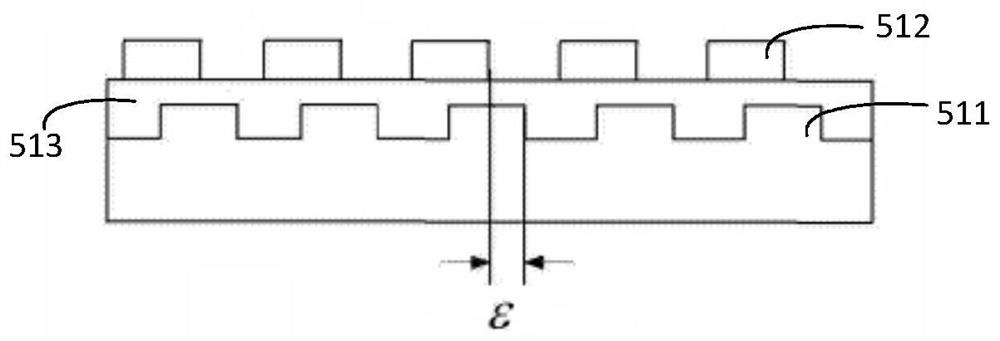

[0128] Step S1: providing an overlay mark 510, projecting the measurement light spot on the overlay mark 510, and being reflected by the overlay mark 510 to form diffracted light;

[0129] Step S2: adjust the overlay mark 510 to the first position, move the overlay mark 510 in multiple steps along the direction of the horizontal component of the measurement spot, and obta...

PUM

| Property | Measurement | Unit |

|---|---|---|

| Diameter | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com