Integrated three-dimensional liquid cooling pipe network flow distribution device

A technology of a distribution device and a liquid cooling tube, which is applied in the field of radar detection, can solve the problems of inability to adapt to large heat consumption and a highly integrated front environment, and achieve the effect of reducing front space requirements, facilitating processing, and realizing front effects.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

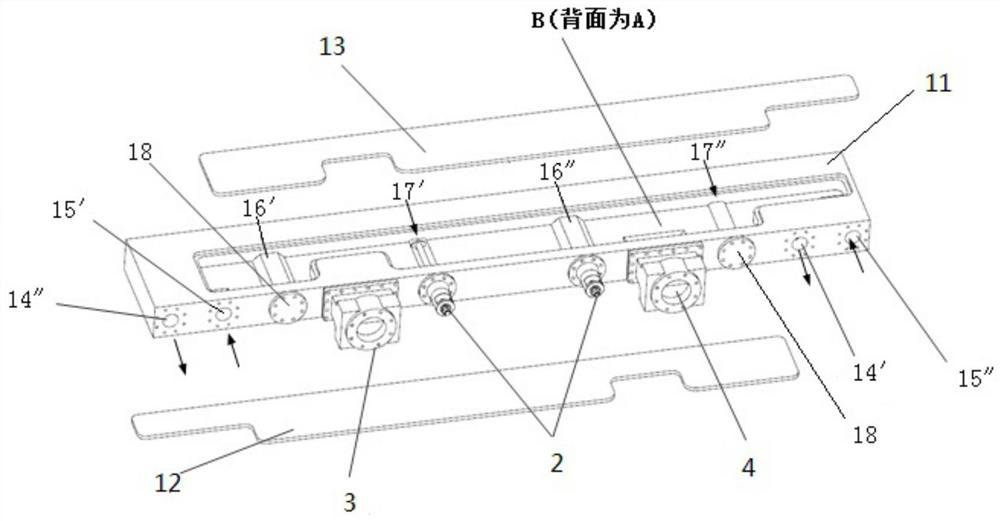

[0048] like figure 1 As shown, an integrated three-dimensional liquid-cooled pipe network flow distribution device includes a distribution assembly 1, a liquid supply adapter 3, and a liquid return adapter 4. The distribution assembly 1 includes a liquid supply collection chamber A, a liquid return A collection chamber B, the liquid supply collection chamber A includes a plurality of liquid supply ports for connecting to the integrated network pipe, and the liquid return collection chamber B includes a plurality of liquid return ports connected to the integrated network pipe; the liquid supply The adapter 3 is connected to the distribution assembly 1 and communicated with the liquid supply collection chamber A, and the liquid return adapter 4 is connected to the distribution assembly 1 and communicated with the liquid return collection chamber B.

[0049] Specifically, such as figure 1 As shown, the distribution assembly 1 includes a distribution main body 11, a first cover p...

Embodiment 2

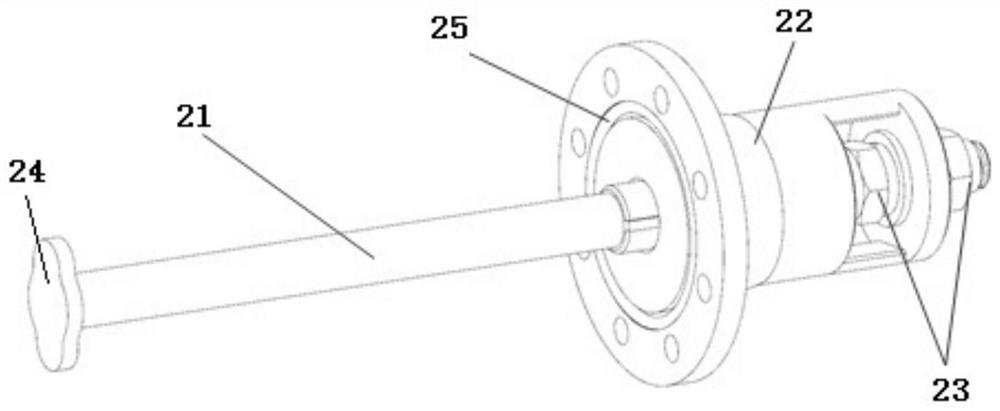

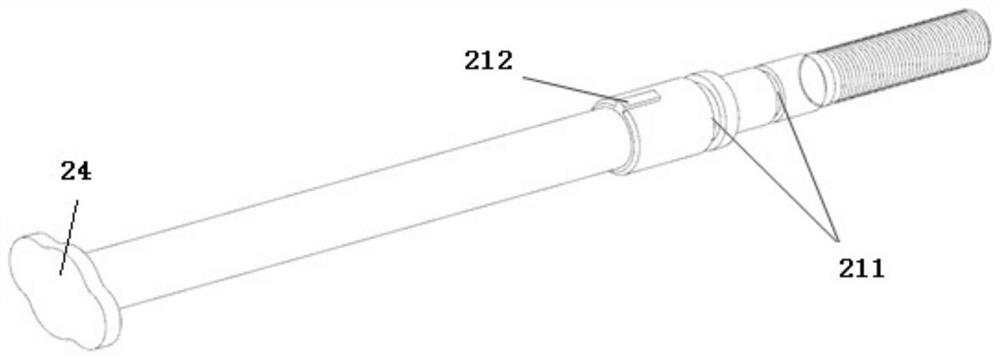

[0060] like figure 1 , figure 2 As shown, on the basis of the first embodiment above, this embodiment also includes two flow adjustment assemblies 2; the flow adjustment that can change the cross-sectional area at the liquid supply port or / and liquid return port The assembly 2 is connected to the distribution assembly 1. Since the middle front pipeline is integrated with the middle front, the inlet of the flow channel is located inside the distribution / collection cavity. Therefore, in this embodiment, the middle front The integrated network management 7 has two groups of cooling pipelines, and each cooling pipeline is provided with a flow regulating assembly 2 for fine-tuning the flow of the integrated network management 7 at the center front. Specifically, the middle front liquid return channel corresponding to the middle front liquid return port 17' is connected to the flow adjustment assembly 2, and the middle front liquid supply channel corresponding to the middle front ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com