Co2 separation & liquefaction system and method

A liquefaction system, CO2 technology, applied in the field of CO2 capture technology, can solve problems such as reducing the effect of system capture CO2

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0021] The operating environment of the present invention is described for a CO2 separation and liquefaction system for exhaust gases from fossil fuel combustion. However, those skilled in the art will appreciate that the present invention is equally applicable to the separation and liquefaction of CO2 from other carbon gas streams. While embodiments of the invention will be described with respect to carbon capture and storage systems for fossil fuel fired power plants, embodiments of the invention are equally applicable to CO2 separation and liquefaction for other industrial processes.

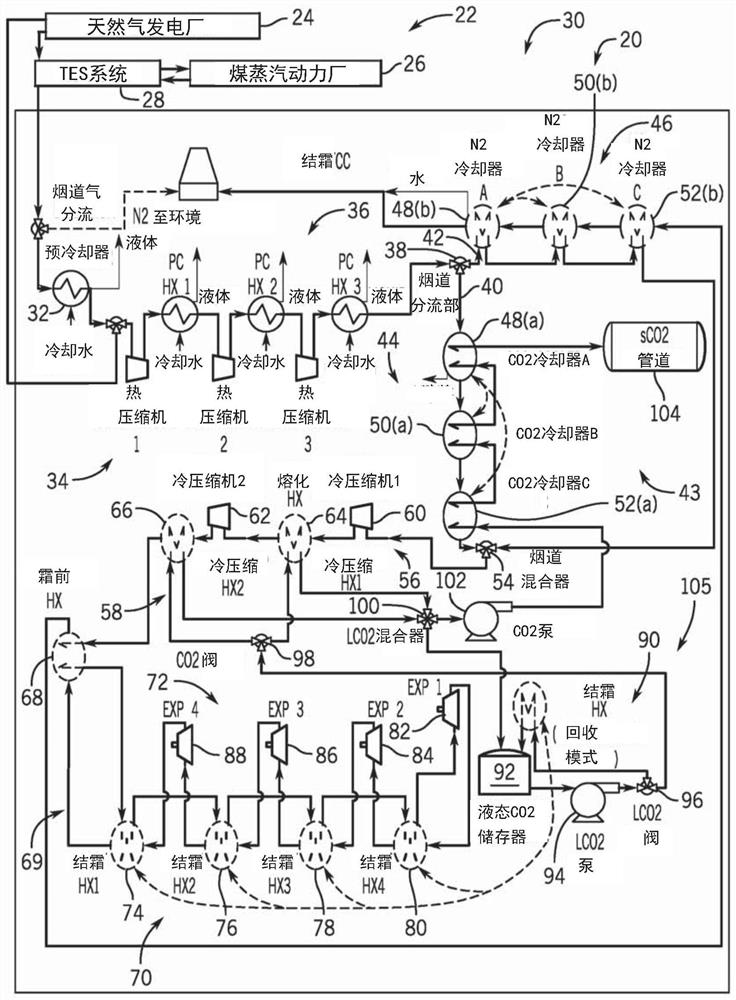

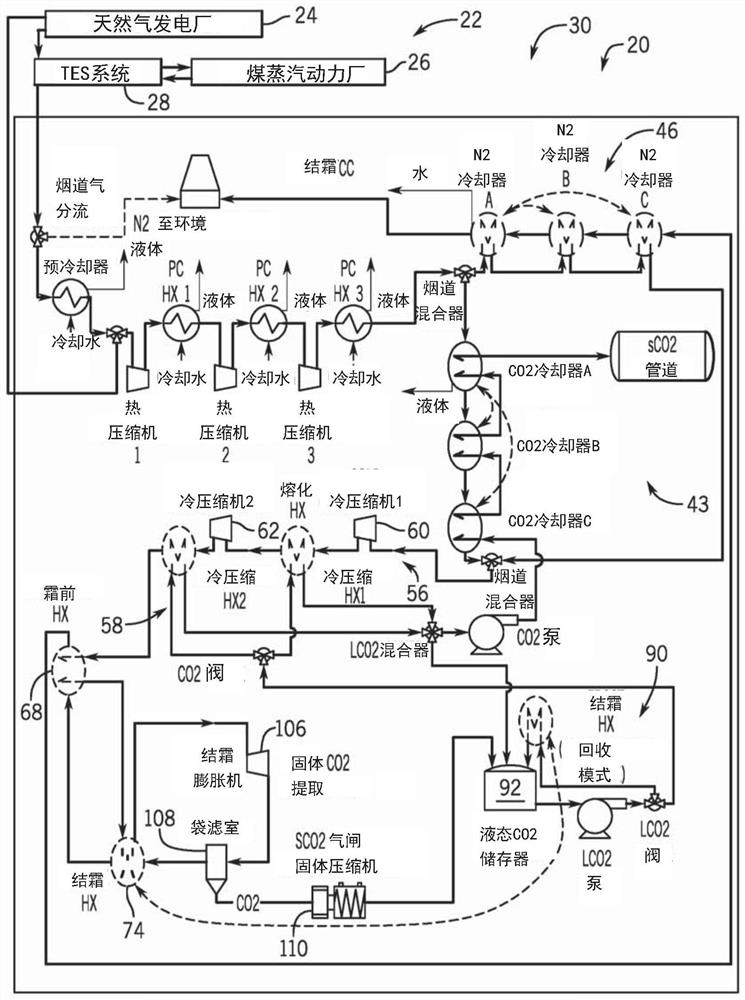

[0022] refer to figure 1 , according to an embodiment of the present invention, a CO2 separation and liquefaction system 20 with interstage warming expansion is shown. CO 2 separation and liquefaction system 20 is shown coupled to combined cycle power plant 22 including natural gas power plant 24 , coal steam power plant 26 , and thermal energy storage (TES) system 28 . Natural gas power pl...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - Generate Ideas

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com