Zero-lactose full milk powder and preparation method thereof

A technology of whole milk powder and zero lactose, applied in dairy products, milk preparations, other dairy products, etc.

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

[0021] Embodiment 1: long-term hydrolysis at low temperature

[0022] A preparation method of zero-lactose whole milk powder, comprising the following steps:

[0023] 1.1) The raw milk has passed the inspection and is collected into the milk storage tank, and the temperature is maintained at 6°C;

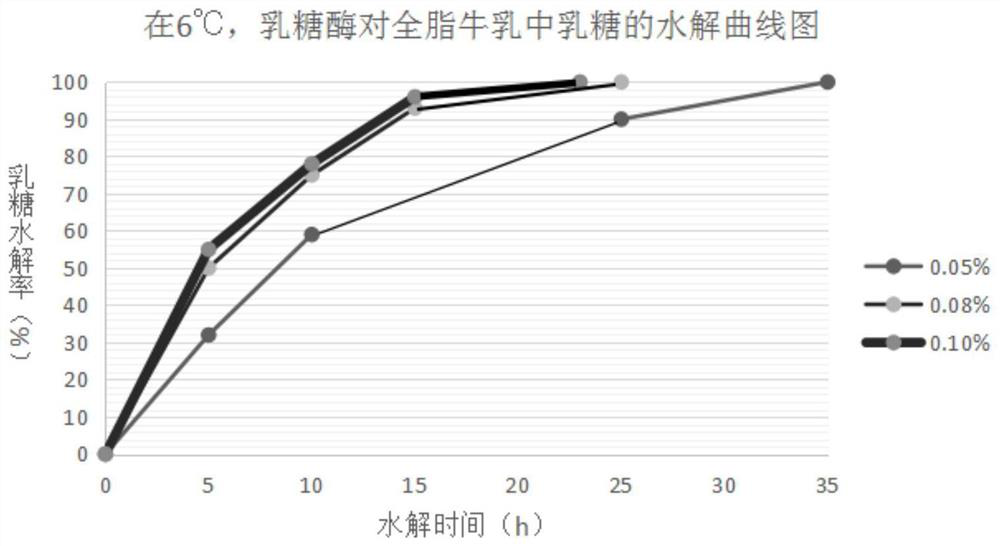

[0024] 1.2) Add β-galactosidase to raw milk, the addition amount is 0.05%, 0.08%, 0.10%, stir evenly; and carry out hydrolysis at 6°C;

[0025] 1.3) Re-sampling and testing require that the lactose hydrolysis rate is above 98% and the residual lactose content is below 0.06%, to obtain lactose-free whole milk;

[0026] 1.4) The obtained lactose-free whole milk is subjected to fat separation and powder milling to obtain lactose-free whole milk powder; and sampling and testing are carried out to meet the national standard zero-lactose requirement.

[0027] like figure 1 As shown, the lactose detection results of the whole milk powder prepared by the preparation method of Example 1: ...

Embodiment 2

[0028] Embodiment 2: high temperature short time hydrolysis

[0029] A preparation method of zero-lactose whole milk powder, comprising the following steps:

[0030] 2.1) After passing the inspection, the raw milk is put into the milk storage tank, and the temperature is maintained at 6°C;

[0031] 2.2) Raw milk is pasteurized at 65°C to 85°C / 15 seconds, then cooled to 40°C;

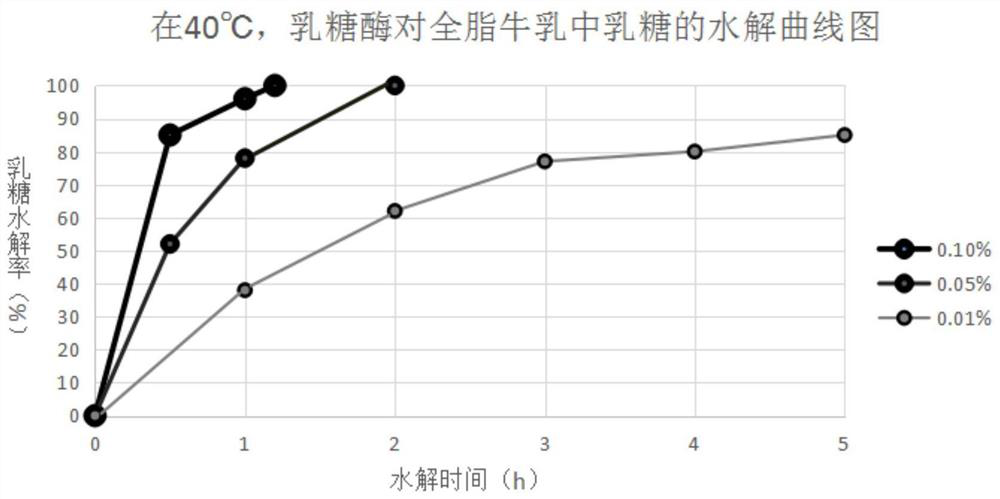

[0032] 2.3) Add β-galactosidase to the raw milk, respectively, in the amounts of 0.01%, 0.05%, and 0.10%, stir evenly, and perform hydrolysis at 40°C;

[0033] 2.4) Re-sampling and testing, it is required that the lactose hydrolysis rate is above 98%, and the lactose residue is below 0.06%, to obtain lactose-free whole milk;

[0034] 2.5) The obtained lactose-free whole milk is subjected to fat separation and powder milling to obtain lactose-free whole milk powder; and sample testing is carried out to meet the national standard zero-lactose requirement.

[0035] like figure 2 As shown, the lactose d...

Embodiment 3

[0036] Embodiment 3: making whole milk powder

[0037] Process flow: raw milk inspection→pretreatment→preheating homogenization and sterilization→lactose hydrolysis→concentration→spray drying→cooling→powder sieving→packaging→finished product

[0038] 3.1) Raw milk inspection and pretreatment: Raw milk must be fresh, not mixed with abnormal milk, with a specific gravity of 1.028-1.032 (20°C), acidity not exceeding 20°T, fat content of not less than 3.1%, and milk solids not low 11.5%; the number of miscellaneous bacteria does not exceed 200,000 / ml; qualified milk must be filtered and purified to obtain raw milk;

[0039] 3.2) Preheating and homogenizing sterilization: the purpose is to kill microorganisms in raw milk and destroy enzyme activity; generally adopt high-temperature short-time sterilization method, or ultra-high temperature instantaneous sterilization method; if using sheet or tube type sterilizer, usually use The best sterilization conditions are 80-85°C for 30 se...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com