Suction filtration experiment device and method

An experimental device and filter paper technology, applied in separation methods, chemical instruments and methods, filtration and separation, etc., can solve the problems that affect the accurate reading of filtrate volume, affect the accuracy of reading, and filter paper is easy to hang pulp, etc., which is conducive to accurate measurement. Effect

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

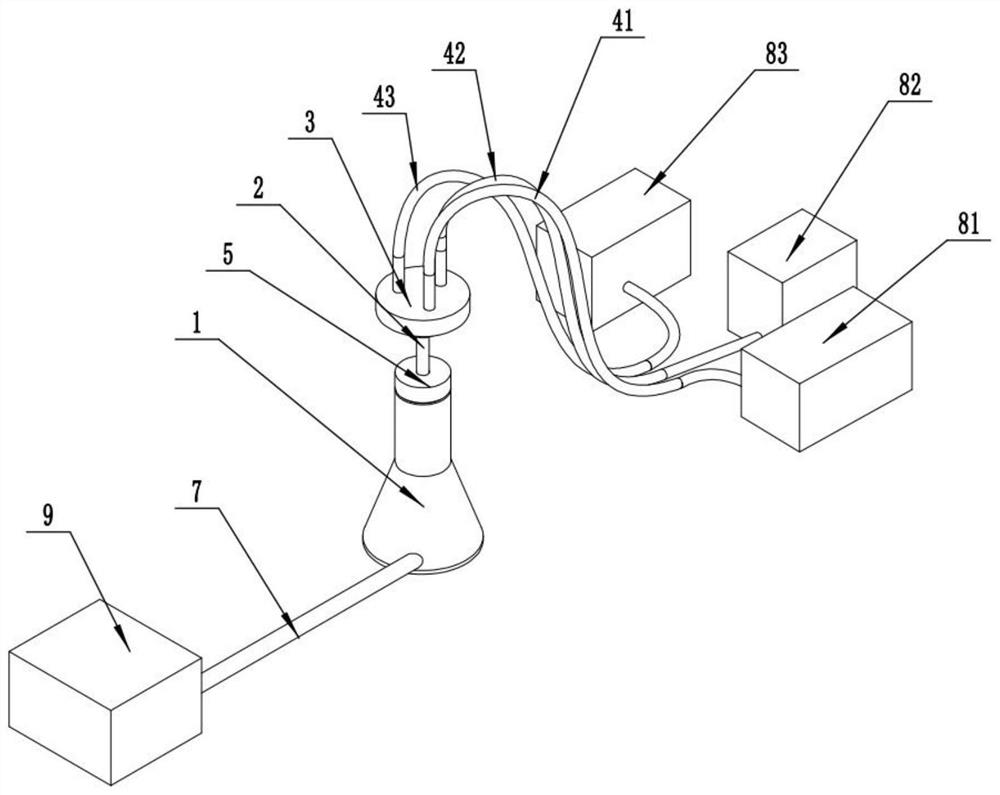

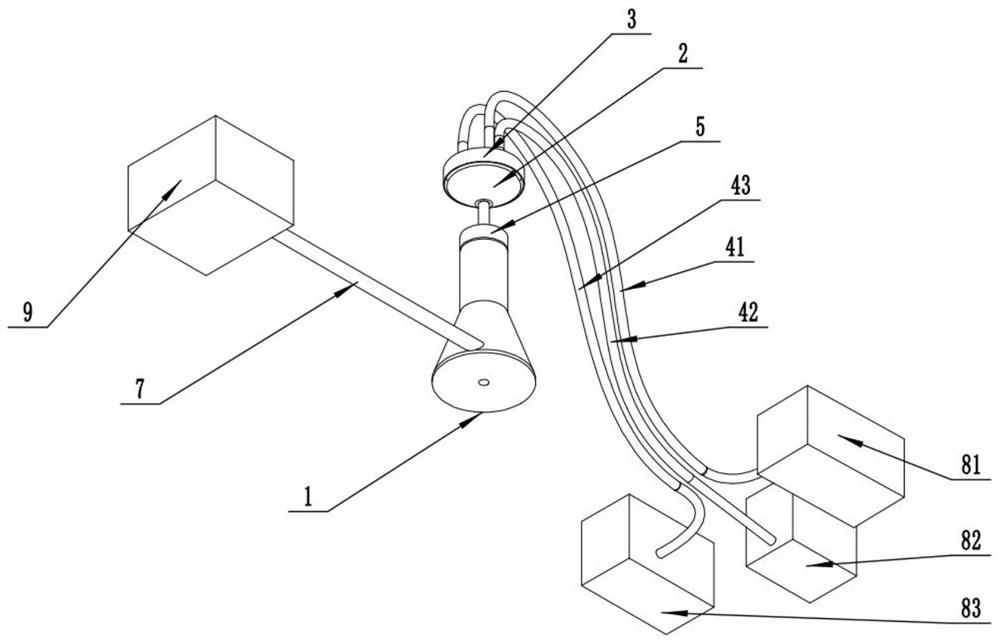

[0051] In a typical implementation of the present invention, this embodiment discloses a suction filtration experimental device, comprising:

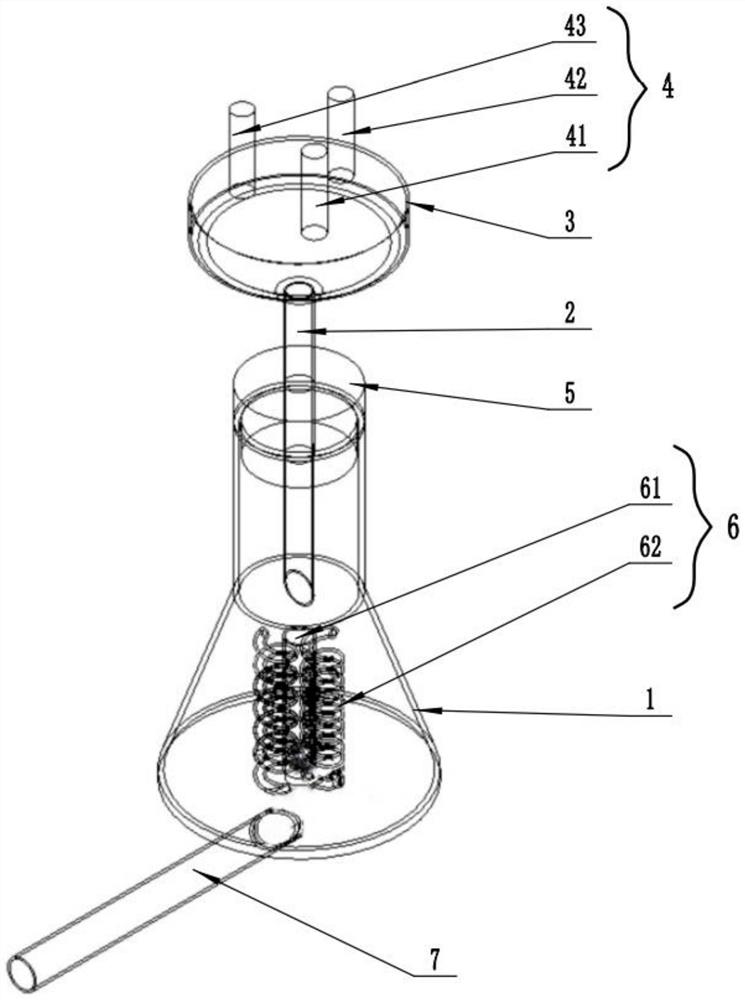

[0052] The bottle body 1 has a cavity inside, an opening is opened on the top, and the bottle stopper 5 is detachably connected to the opening;

[0053] Funnel 2, the top opening is laid with filter paper, and the bottom opening passes through the bottle stopper 5 and enters the bottle body 1;

[0054] The pressurized container 3 is provided with a detachable cover on the top of the funnel 2, and can close the top of the funnel 2. The pressurized container 3 is provided with a plurality of pressurized gas inlets, and each pressurized gas inlet is respectively connected to a pressure source 8;

[0055] The negative pressure source 9 is connected to the bottle body 1;

[0056] The measuring pipe 6 with the main body in a spiral shape is arranged in the bottle body 1, the entrance of the measuring pipe 6 is located directly below the funn...

Embodiment 2

[0083] In a typical implementation of the present invention, this embodiment discloses a suction filtration experimental method, using the suction filtration experimental device as described in Example 1, comprising the following steps:

[0084] Assemble the suction filtration experimental device, and keep the top opening of the funnel 2 open;

[0085] Put the sludge on the filter paper;

[0086] The pressurized container 3 is covered and connected to the top opening of the funnel 2;

[0087] start the server;

[0088] According to the experimental requirements, select any one or several of the first pressure source 81 to the third pressure source 83, and start the pressure source 8;

[0089] Start negative pressure source 9;

[0090] Take the reading from the server; or take the reading manually.

PUM

| Property | Measurement | Unit |

|---|---|---|

| Central angle | aaaaa | aaaaa |

Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com