Bifunctional catalyst applied to integration of CO2 capture and methanation in flue gas

A dual-function catalyst and methanation technology, applied in physical/chemical process catalysts, metal/metal oxide/metal hydroxide catalysts, gas fuels, etc., can solve the problems of high catalyst cost, expensive precious metals, and multi-energy

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

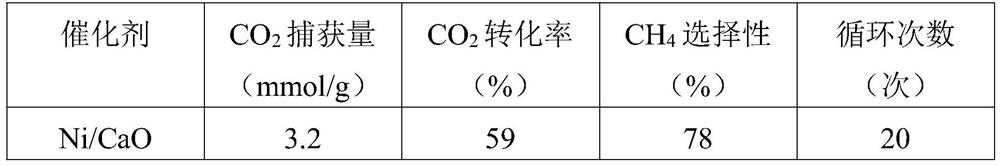

[0028] Embodiment 1.Ni / CaO catalyst is applied to CO in flue gas 2 Capture-methanation integrated reaction

[0029] (1) Catalyst preparation

[0030] 1. Preparation of Vector

[0031] The carrier of the catalyst is prepared by a sol-gel method. Weigh 4.2112g of calcium nitrate tetrahydrate, dissolve it in 50mL of deionized water, add 8.6830g of ammonium citrate to the above solution, after fully dissolving, stir in an oil bath at 90°C until a gel is formed. Then the prepared gel was dried in an oven at 100°C for 12h, calcined in a muffle furnace at 800°C for 4h, and the heating rate was 10°C / min, and finally the CaO support was obtained.

[0032] 2. Catalyst Preparation

[0033] The catalyst is prepared by impregnation method. Weigh 0.4955 g of nickel nitrate hexahydrate, dissolve it in 30 mL of absolute ethanol, and add 1.0000 g of the CaO carrier prepared above. Magnetically stirred at 25°C for 3h, evaporated to dryness in a water bath at 90°C, dried in an oven at 100°...

Embodiment 2

[0037] Embodiment 2.Ni / MgCaO catalyst is applied to CO in flue gas 2 Capture-methanation integrated reaction

[0038] (1) Catalyst preparation

[0039] 1. Preparation of Vector

[0040] The carrier of the catalyst is prepared by a sol-gel method. Weigh 4.2112g of calcium nitrate tetrahydrate and 1.0667g of magnesium nitrate hexahydrate, dissolve them in 50mL of deionized water, add 8.6830g of ammonium citrate to the above solution, after fully dissolving, stir in an oil bath at 90°C until a gel is formed . Then the prepared gel was dried in an oven at 100°C for 12h, calcined in a muffle furnace at 800°C for 4h, and the heating rate was 10°C / min, and finally the MgCaO support was obtained.

[0041] 2. Catalyst preparation

[0042] The catalyst is prepared by impregnation method. Weigh 0.4955 g of nickel nitrate hexahydrate, dissolve it in 30 mL of absolute ethanol, and add 1.1000 g of the above-prepared MgCaO carrier. Stir magnetically at 25°C for 3h, evaporate to drynes...

Embodiment 3

[0046] Embodiment 3.Ni / ZrCaO catalyst is applied to CO in flue gas 2 Capture-methanation integrated reaction

[0047] (1) Catalyst preparation

[0048] 1. Preparation of Vector

[0049] The carrier of the catalyst is prepared by a sol-gel method. Weigh 4.2112g of calcium nitrate tetrahydrate and 0.4706g of zirconium nitrate pentahydrate, dissolve them in 50mL of deionized water, add 8.6830g of ammonium citrate to the above solution, after fully dissolving, stir in an oil bath at 90°C until a gel is formed . Then the prepared gel was dried in an oven at 100°C for 12h, calcined in a muffle furnace at 800°C for 4h at a heating rate of 10°C / min, and finally the ZrCaO support was obtained.

[0050] 2. Catalyst preparation

[0051] The catalyst is prepared by impregnation method. Weigh 0.4955 g of nickel nitrate hexahydrate, dissolve it in 30 mL of absolute ethanol, and add 1.1000 g of the ZrCaO carrier prepared above. Stir magnetically at 25°C for 3h, evaporate to dryness in...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com