Pintle chain automatic assembling device and assembling method thereof

A technology of automatic assembly device and pinning chain, applied in the direction of metal chain, etc., can solve the problems of low efficiency and labor consumption, and achieve the effect of high degree of automation, improved quality and reasonable design

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

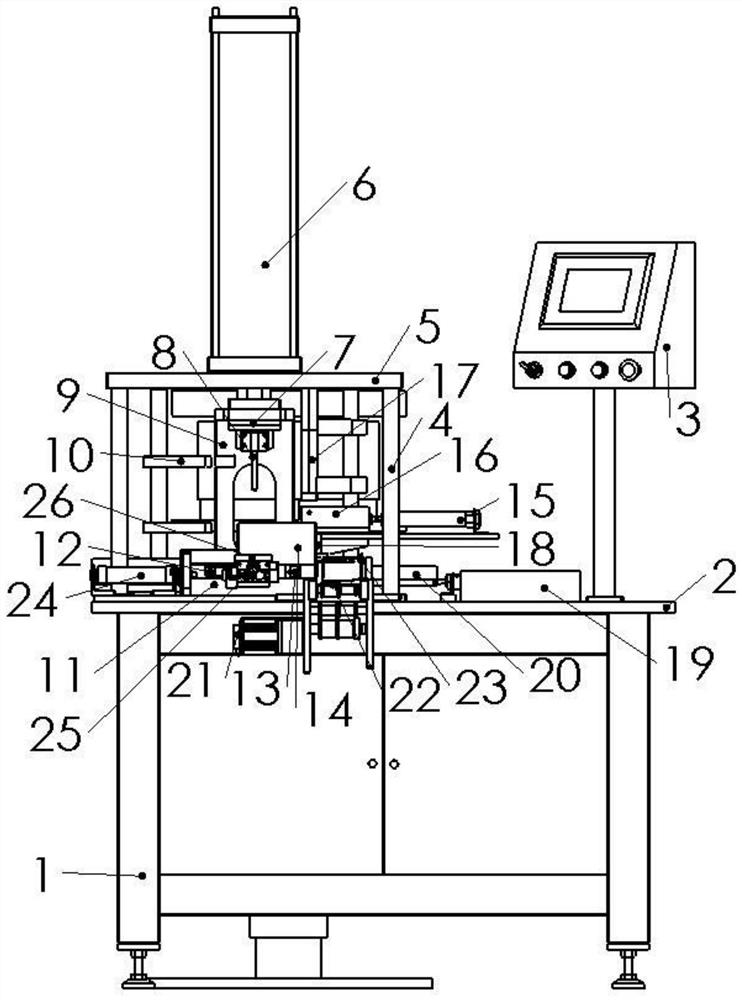

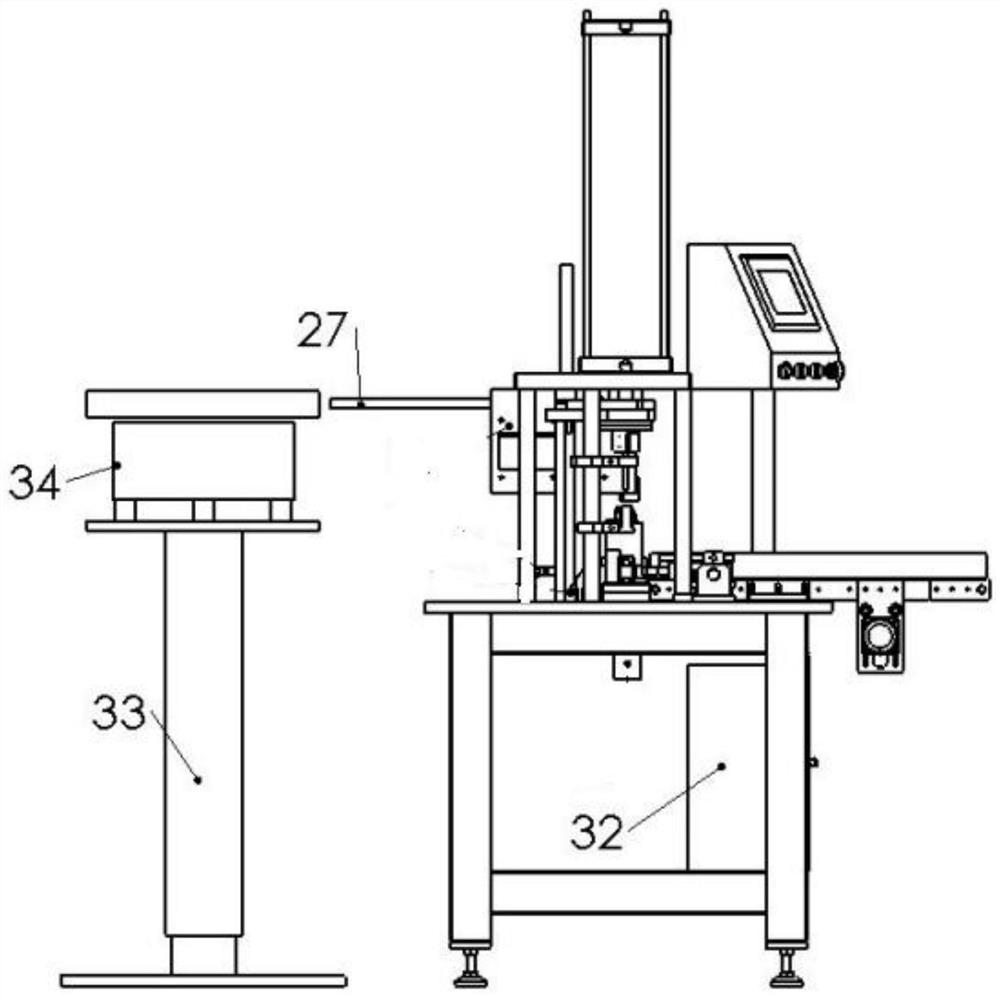

[0029] refer to Figure 1-2 , an automatic assembly device for pin-joint chains, comprising a work frame 1, a workbench 2 is fixed on the upper end of the workbench 1, a control panel 3 is installed on one side of the top surface of the workbench 2, and a vibration plate support 33 is placed on the rear side 33 is fixed with a vibrating plate 34, the output end of the vibrating plate 34 is fixedly connected with a feeding pipe 27, an electrical box 32 is arranged in front of the work frame 1, and a column 4 is installed on the workbench 2, and the column 4 is provided with four and is rectangular. Distributed on the workbench 2, a hydraulic cylinder installation table 5 is fixed on the top of the column 4, a hydraulic cylinder 6 is fixed on the hydraulic cylinder installation table 5, and the output end of the hydraulic cylinder 6 is connected with a flange 7 and a flange 7 by screws. A thimble 8 and a positioning base part 9 are fixed, guide rails 10 are provided on both side...

Embodiment 2

[0032] This embodiment is basically the same as Embodiment 1, preferably, the assembly method of the device

[0033] S1. Put the pin shaft on the vibrating plate 34. After the vibrating plate 34 is started, the pin shaft will be automatically put in place through the feeding pipe 27 and the feeding steering member 17, and the chain link workpiece will be placed on the conveyor belt 22 and automatically transported in place, and the signal will be fed back to the system.

[0034] S2. The signal of the system feeding chain link cylinder 19 is closed, the pushing cylinder is in place, the signal is fed back to the system, the signal of the system feeding chain link cylinder 19 is disconnected, the pushing cylinder returns to the position, and the signal is fed back to the system.

[0035] S3. The system sends a signal to the pin delivery cylinder 15 to close, the push cylinder is in place, the signal is fed back to the system, the system sends a signal to the pin delivery cylinder...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com