Cutting device for modified plastic master batch production and using method thereof

A technology of plastic masterbatch and cutting device, applied in heating device, drying gas arrangement, dryer, etc., can solve the problem of difficulty in ensuring uniform particle shape

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment

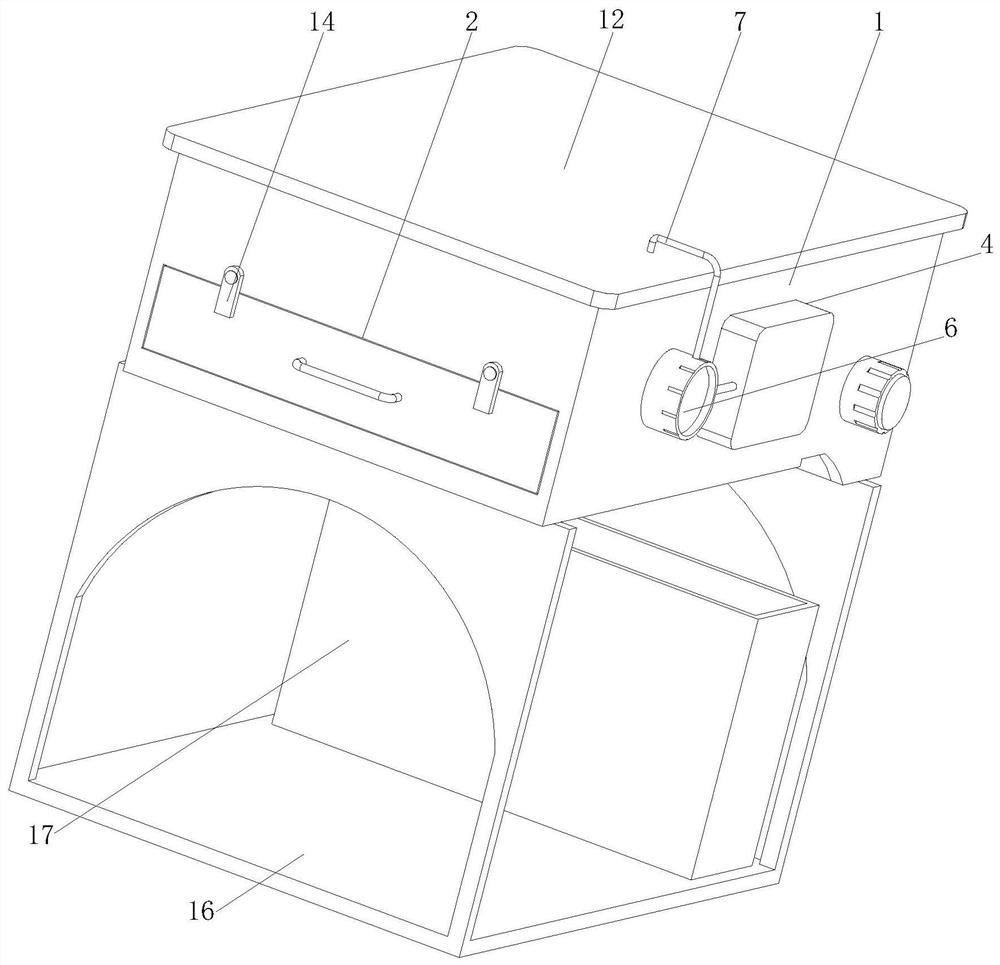

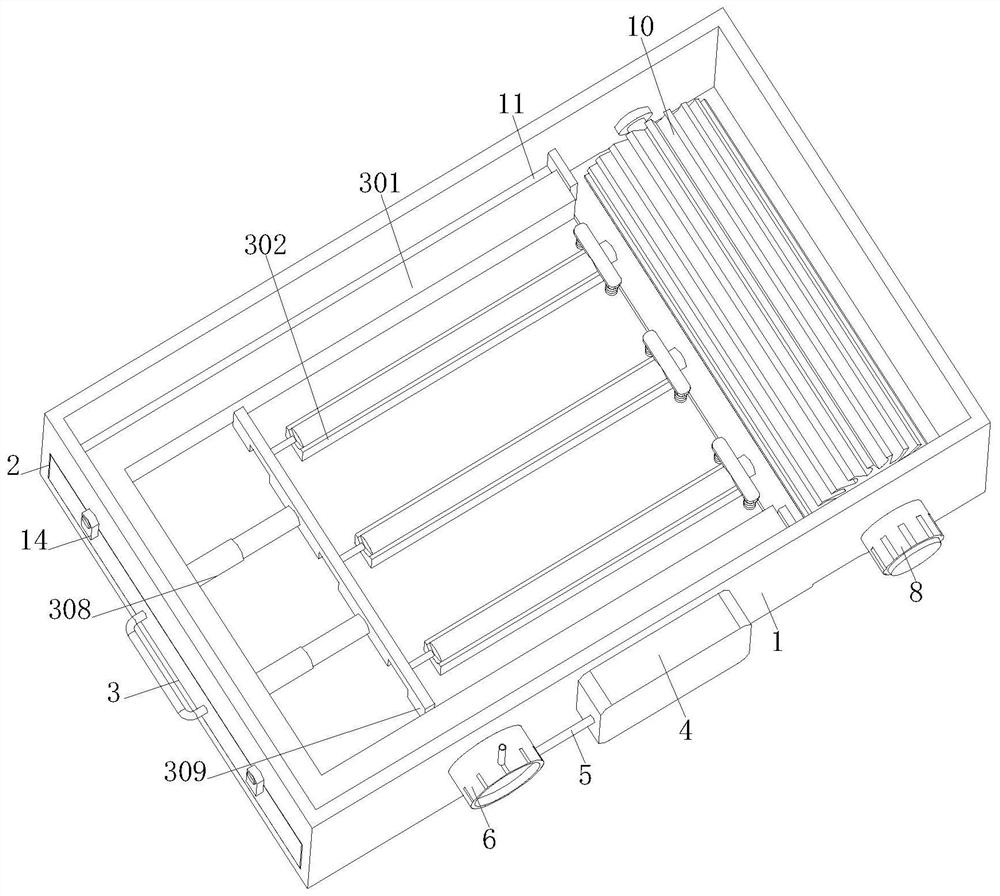

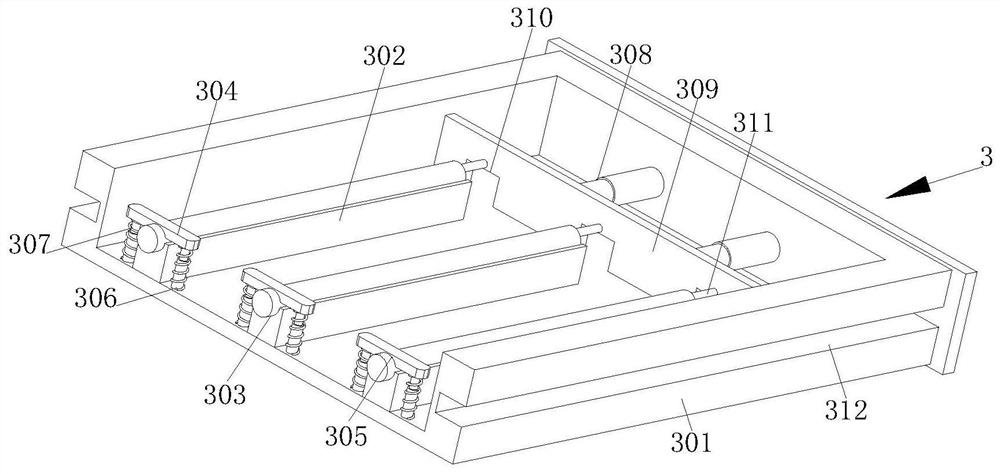

[0032] Such as Figure 1-4 As shown, a cutting device for the production of modified plastic masterbatch proposed by an embodiment of the present invention includes a cutting box 1, one side of the cutting box 1 is provided with a feeding port 2, and the inner wall of the feeding port 2 is connected with a conveying mechanism 3. The feeding port 2 is arranged on one side of the cutting box 1 and communicated with the inside of the cutting box 1, so that the conveying mechanism 3 can pass through the feeding port 2 and move horizontally and linearly inside the cutting box 1. When loading the plastic rods, only the conveying mechanism 3 needs to be slid out from the feeding port 2, and then the plastic rods are placed in the first arc-shaped groove 303 on the top of the discharge plate 302, when the plastic rods are placed When in the first arc groove 303, when the telescopic rod 306 and the spring 307 interact, the second arc groove 305 at the bottom of the positioning plate 304 ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com