Intelligent rotating disc type in-mold component inserter

A turntable, insert-in technology, used in household components, household appliances, other household appliances, etc., can solve problems such as poor control of manual insertion, inability to ensure injection quality, affecting production efficiency, etc., and achieve high work efficiency. , the effect of good quality and low labor intensity

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment Construction

[0032] The present invention will be further described below in conjunction with specific embodiments and accompanying drawings.

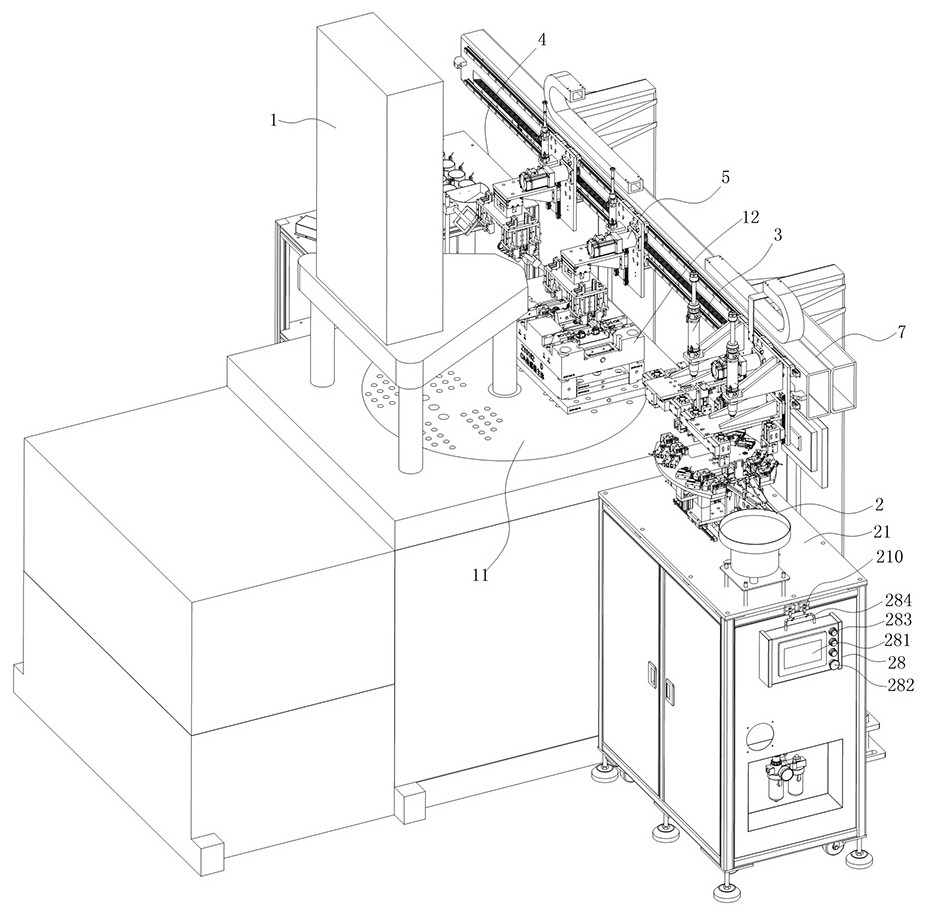

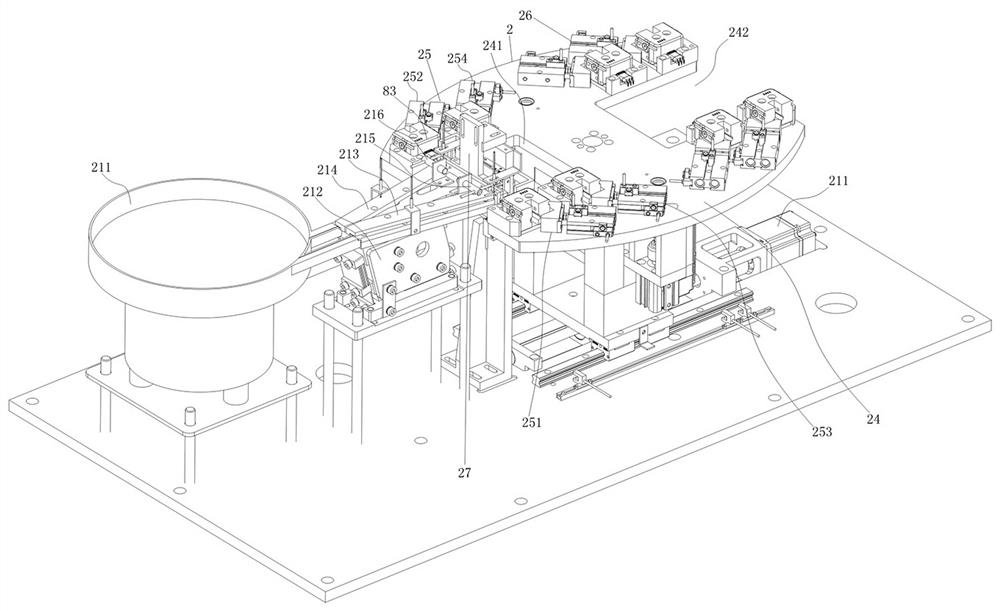

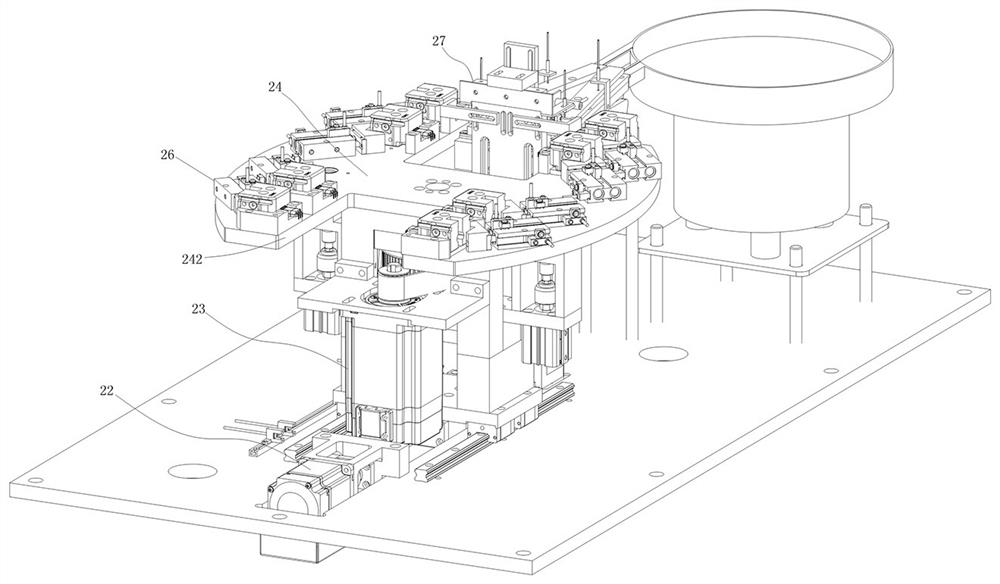

[0033] See Figure 1-13 As shown, it is an intelligent turntable type in-mold inserter, which includes: a vertical injection molding machine 1 , a feeding inserter device 2 , a first conveying device 3 , an unloading device 4 , and a second conveying device 5 .

[0034] Both the first conveying device 3 and the second conveying device 5 are installed on the same gantry 7, which has a more compact structure, lower cost and less space.

[0035] The vertical injection molding machine 1 has a rotatable turntable 11 and a motor assembly for driving the turntable 11 to rotate. The turntable 11 is equipped with a mold 12 for positioning hardware 81 and jig 83, and the motor assembly drives the turntable 11. Rotate to transfer the mold 12 to the vertical injection molding machine 1, and the vertical injection molding machine 1 injects plastic parts 82 on ...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com