Material mixing device for ceramic clay manufacturing

A mixing device and clay technology, applied in the field of clay mixing, can solve the problems of poor control of the input time of mixing materials, uneven clay firing, etc., and achieve the effect of sufficient combustion

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

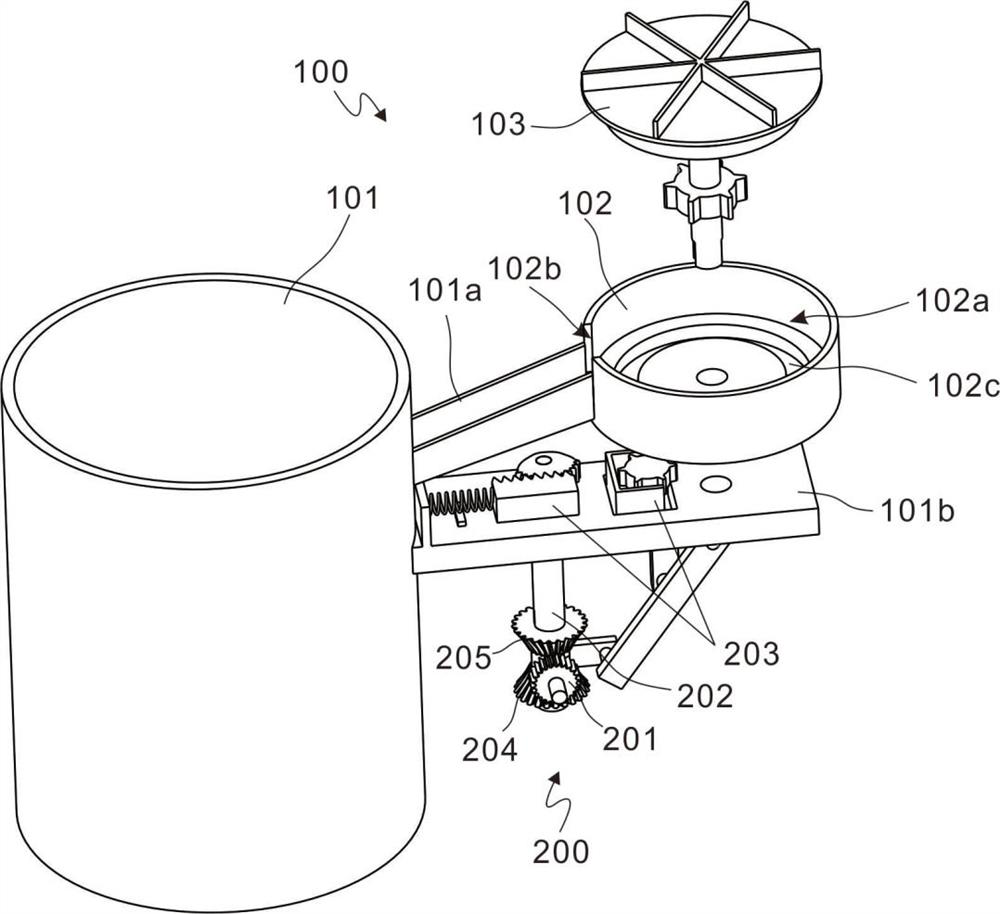

[0022] refer to figure 1 , figure 2 , is the first embodiment of the present invention, which provides a mixing device for ceramic clay production, including a mixing assembly 100 and a driving assembly 200 .

[0023] The mixing assembly 100 includes a melting furnace 101, a feeding tray 102 and a steering wheel 103. An inclined slideway 101a is provided on the outer wall of the melting furnace 101, and the sliding path 101a is connected to the feeding tray 102, and the steering wheel 103 is installed in the feeding tray 102 and Can rotate in the feeding tray 102. A mounting plate 101 b is disposed on the outer wall of the melting furnace 101 , and the mounting plate 101 b extends toward the bottom of the feeding tray 102 . A round shaft 103a is provided at the bottom of the steering wheel 103, and the round shaft 103a passes through the feeding tray 102 and is connected to the mounting plate 101b.

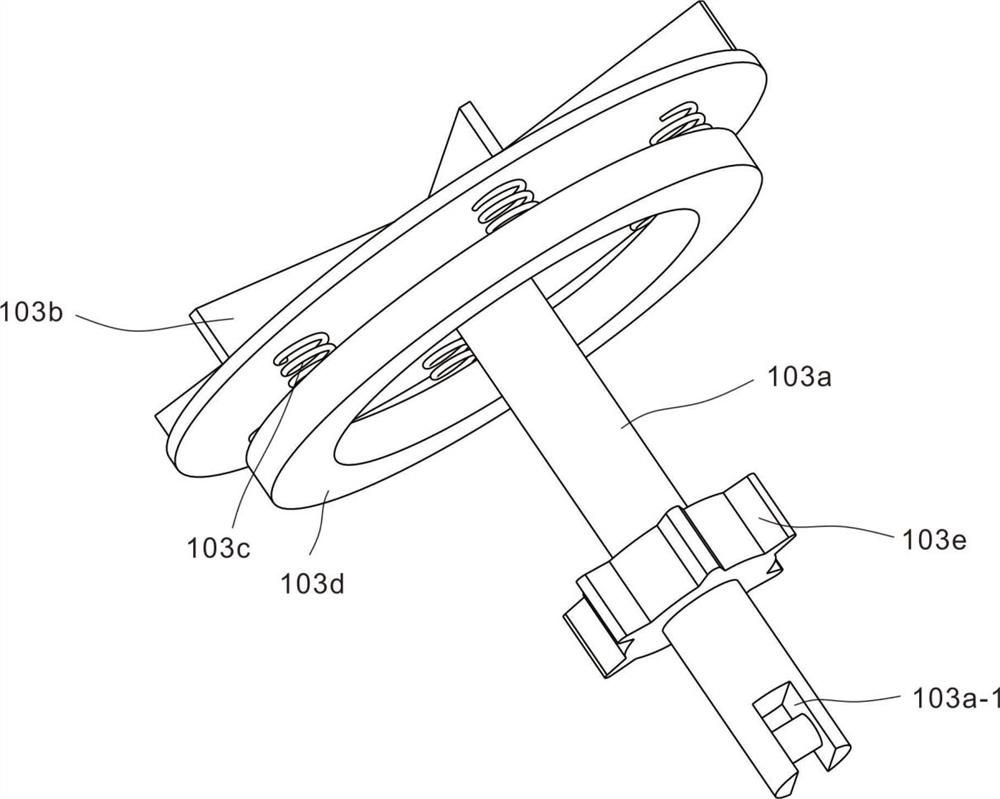

[0024] The top surface of the steering plate 103 has a tendency to inclin...

Embodiment 2

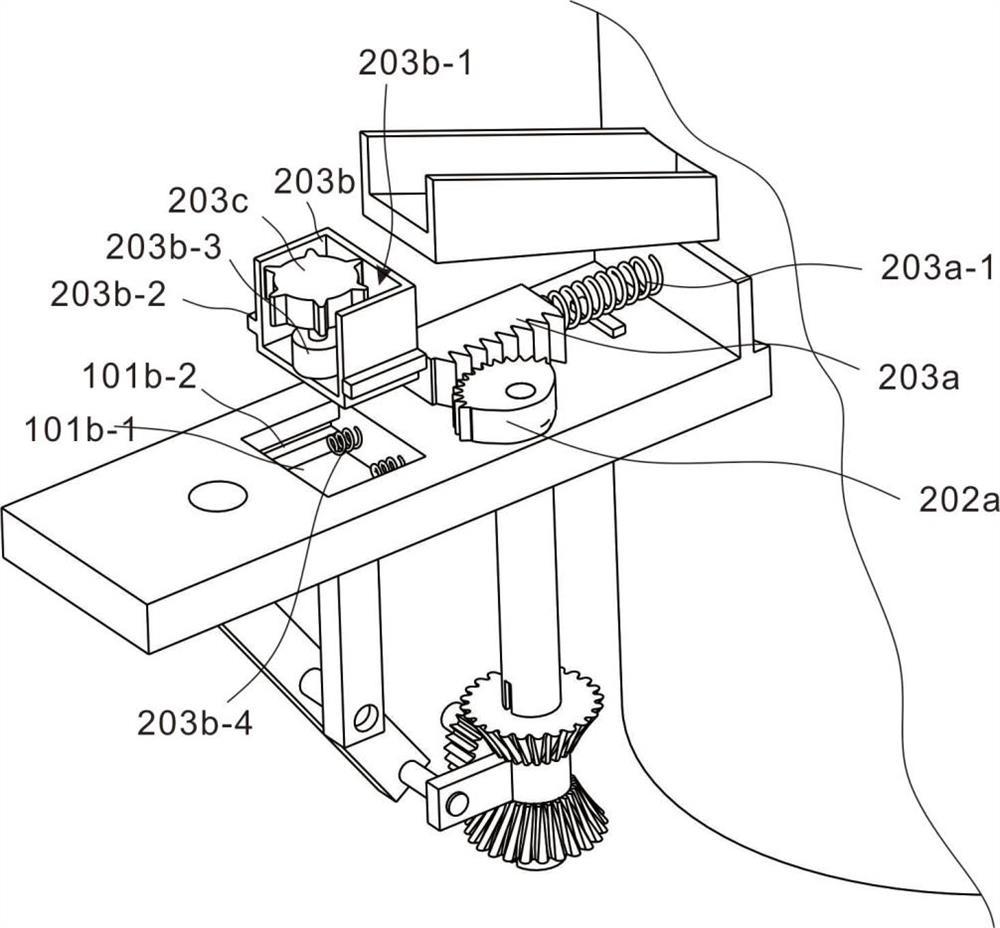

[0030] refer to Figure 2~Figure 4 , which is the second embodiment of the present invention, this embodiment is based on the previous embodiment, the toggle member 203 includes a tooth block 203a, a tooth seat 203b and a second gear 203c, and the tooth seat 203b is movably installed on the mounting plate 101b; the second The gear 203c is located in the gear seat 203b and driven by the second motor 203b-3; the gear block 203a is horizontally installed on the mounting plate 101b to move horizontally.

[0031] The drive assembly 200 also includes a first bevel gear 204 and a second bevel gear 205, the first bevel gear 204 and the second bevel gear 205 are connected through the sleeve A and the first bevel gear 204 and the second bevel gear 205 are connected to the sleeve. A is symmetrically arranged; the motor gear 201 can mesh with the first bevel gear 204 or the second bevel gear 205 respectively. The first bevel gear 204 and the second bevel gear 205 are sleeved on the rotat...

PUM

Login to view more

Login to view more Abstract

Description

Claims

Application Information

Login to view more

Login to view more - R&D Engineer

- R&D Manager

- IP Professional

- Industry Leading Data Capabilities

- Powerful AI technology

- Patent DNA Extraction

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic.

© 2024 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap