An installation method of spot heat flow sensor for aerodynamic thermal test in wind tunnel

A technology of heat flow sensor and aerodynamic heat, applied in aerodynamic tests, instruments, measuring devices, etc., can solve problems such as fluctuations in heat flow distribution, occurrence of shunt vortices, local flow field structure and influence of aerothermal test results, and achieve improved measurement Data accuracy, the effect of reducing installation errors

- Summary

- Abstract

- Description

- Claims

- Application Information

AI Technical Summary

Problems solved by technology

Method used

Image

Examples

Embodiment 1

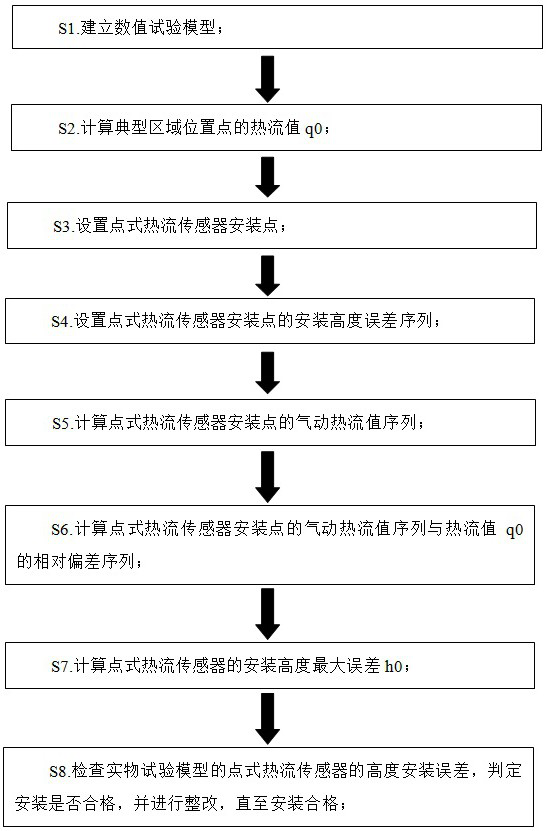

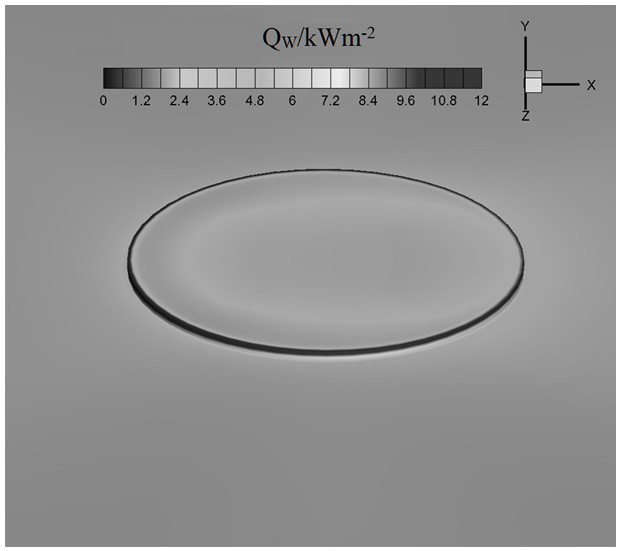

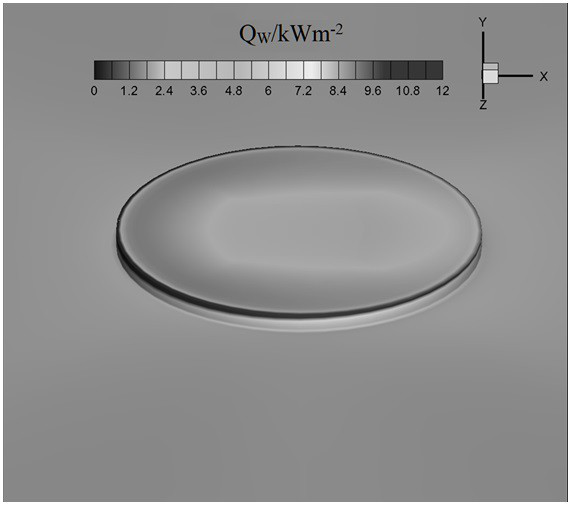

[0053] The physical test model of the present embodiment is a flat plate, and the flow Mach number Ma ∞ =12.0, the flow unit Reynolds number Re ∞ =4.03×10 6 / m, the typical area point is about 0.22m away from the head of the flat model, the diameter is 2mm, the height of the protrusion / depression is 0.05mm and 0.1mm, and the angle of attack is 0°. The obtained local heat flow nephogram is shown in Figure 2a ~ Figure 2d , the obtained aerodynamic heat flow value, aerodynamic heat flow value and h0 value are shown in Table 1.

[0054]

[0055] From Figure 2a ~ Figure 2d It can be seen in the figure that the discontinuity of the plate is caused by the installation of the simulated point heat flow sensor protrusion / depression, so that the local heat flow has a strong discontinuous distribution. It can be seen that there is a significant difference in the B(h) value for different heights of sensor bumps / sags. Taking N=0.05, comparative analysis shows that only when the bum...

PUM

Login to View More

Login to View More Abstract

Description

Claims

Application Information

Login to View More

Login to View More - R&D

- Intellectual Property

- Life Sciences

- Materials

- Tech Scout

- Unparalleled Data Quality

- Higher Quality Content

- 60% Fewer Hallucinations

Browse by: Latest US Patents, China's latest patents, Technical Efficacy Thesaurus, Application Domain, Technology Topic, Popular Technical Reports.

© 2025 PatSnap. All rights reserved.Legal|Privacy policy|Modern Slavery Act Transparency Statement|Sitemap|About US| Contact US: help@patsnap.com